A Method of Increasing the Air Permeability of Investment Casting Ceramic Model Shell

A technology of investment casting and ceramic molding, which is applied in the direction of casting molding equipment, casting molds, and casting mold components. quality, improve the casting pass rate, and the effect of fine void structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

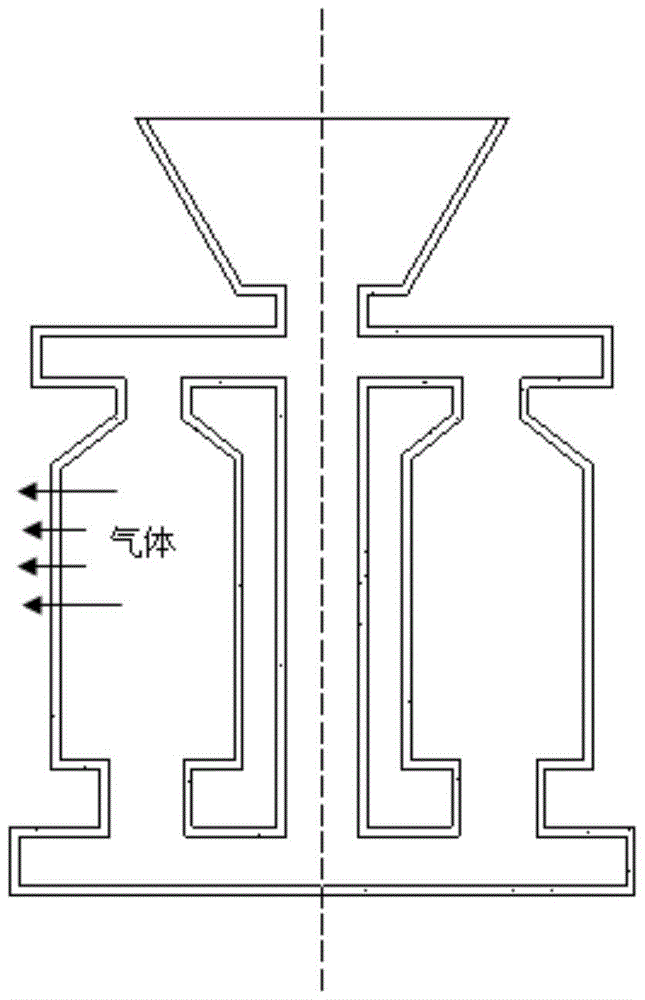

[0023] Make 10 pieces of a small thin-walled structural part, the outer dimension is about 60mm×100mm×250mm.

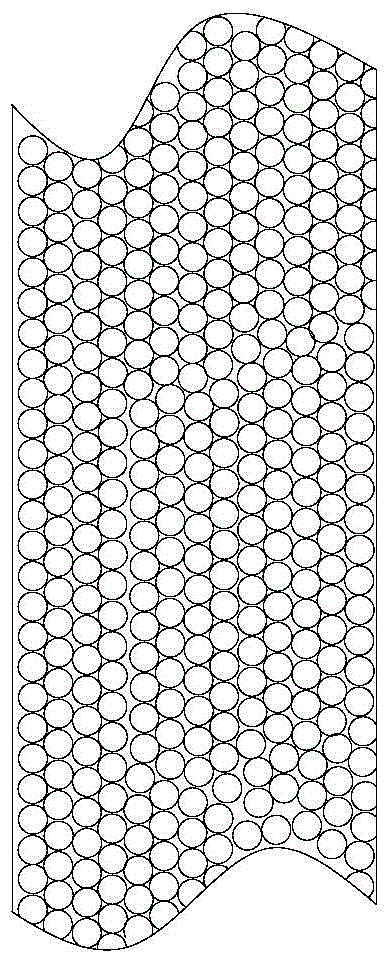

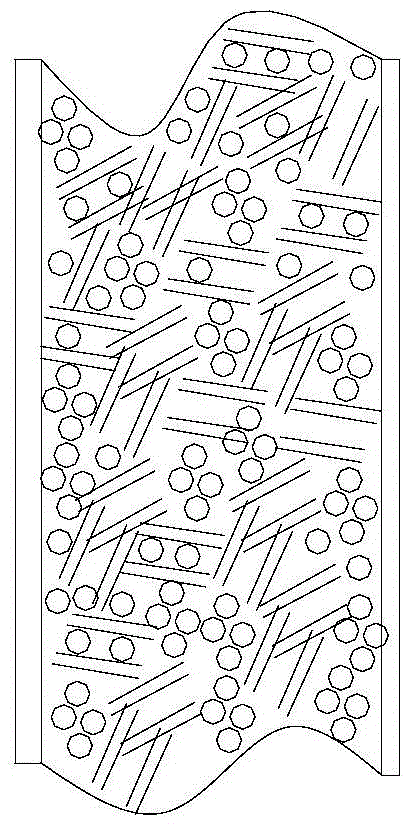

[0024] Weigh the refractory material powder 320# bauxite powder and GRJ26 silica sol of each layer of the reinforcement layer according to the ratio of 4-4.5:1 by mass, and add the polyester fiber into the mixing tank for mixing, and the stirring speed is 400-500r / min , stirred for 24 hours, then added the defoamer n-butanol accounting for 0.5-1wt% of the mass of silica sol in each layer and the wetting agent stearic acid accounting for 0.5-1wt% of the mass of silica sol in each layer, and adjusted the viscosity of the coating to The range required for each layer of coating in the reinforcement layer is to obtain the reinforcement layer coating with polyester fibers added to each layer, and the final sealing layer coating does not add polyester fibers; wherein, the quality of polyester fibers added is 0.5 to 0.7wt of the powder quality of each layer of the reinforcemen...

Embodiment 2

[0036] Make 10 pieces of certain blade parts, the outer dimension is about 150mm×50mm×20mm.

[0037] Weigh the refractory material powder of each layer of the reinforcement layer 320# fused mullite powder and GRJ26 silica sol according to the mass ratio of 3.5-4:1, pour part of the silica sol into the mixing bucket, and put the weighed Pour the powder of each layer into the mixing bucket 3 to 4 times, stir with a mixer while pouring, the stirring speed is 400-500r / min, mix the aramid fiber into the last batch of powder and add it to the mixing bucket, then add the remaining The silica sol was mixed and stirred for 27 hours, and finally, the defoamer n-butanol accounting for 0.5-1 wt% of the mass of each layer of silica sol and the wetting agent stearic acid accounting for 0.5-1 wt% of the mass of each layer of silica sol were added, and the viscosity of the coating was adjusted with deionized water. Adjust to the range required by the coatings of each layer of the reinforcemen...

Embodiment 3

[0041] Make 4 pieces of a large circular part, the outer dimension is about

[0042]Weigh the 320# fused corundum powder and GRJ26 silica sol in the ratio of 3.5-4.5:1 for the refractory material powder of each layer of the reinforcement layer, pour part of the silica sol into the mixing bucket, and divide the weighed powder into Pour into the mixing bucket for 3 to 4 times, stir with a mixer while pouring, the stirring speed is 400-500r / min, mix the aramid fiber into the last batch of powder and add it to the mixing bucket, then add the remaining silica sol and mix for 30 hours , finally add the defoamer n-butanol accounting for 0.5-1wt% of the mass of silica sol in each layer and the wetting agent stearic acid accounting for 0.5-1wt% of the mass of silica sol in each layer, and use deionized water to adjust the viscosity of the coating to the level of each reinforcement layer. The range required for the layer coating is obtained by adding the reinforcement layer coating of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com