Nitrogen-sulfur co-doped carbon material with electro-catalytic oxygen reduction activity and preparation method of carbon material

A nitrogen-sulfur co-doping, electrocatalytic oxygen technology, applied in chemical instruments and methods, physical/chemical process catalysts, circuits, etc., can solve problems such as multi-step, labor-intensive, time-consuming, etc. Remove effects with simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 3g of chicken feathers into a beaker, pour 50ml of acetone into a sonication for 15min, dry in an oven at 110°C, cut the chicken feathers into pieces (about 5mm), pour the broken chicken feathers into the lining of the hydrothermal reaction kettle, add 45g for analysis Pure ammonia water (mass ratio of hair to ammonia water is 1:15), hydrothermal reaction at 120°C for 2 hours. After the reaction kettle is cooled to room temperature, put the ammonia solution in which the amino acid is dissolved in an oven at 110°C until it is dried, and grind the obtained solid with a mortar to obtain solid powder amino acid.

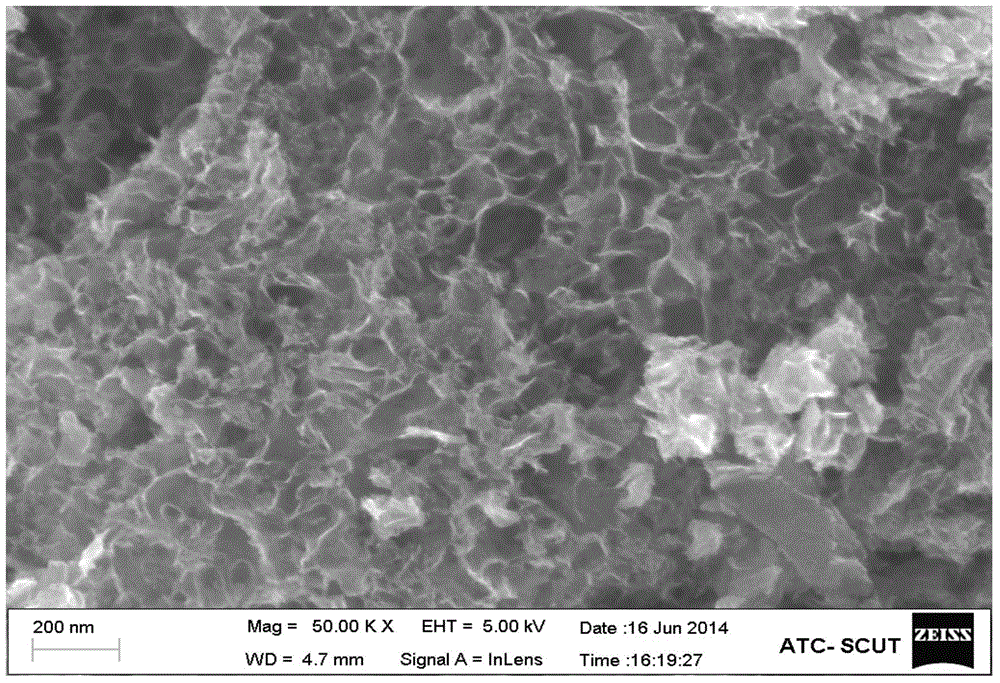

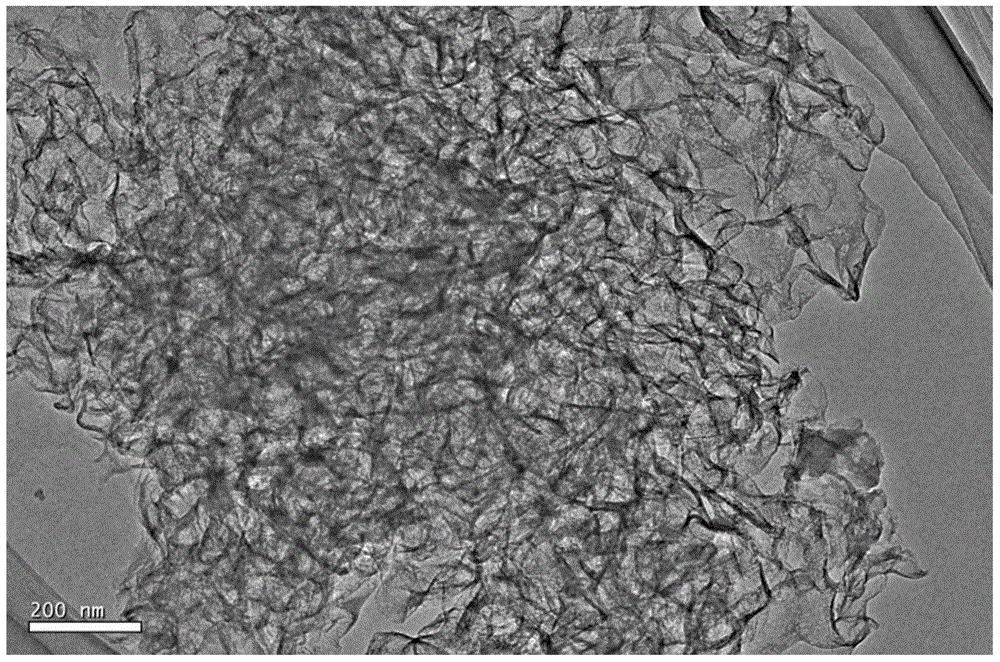

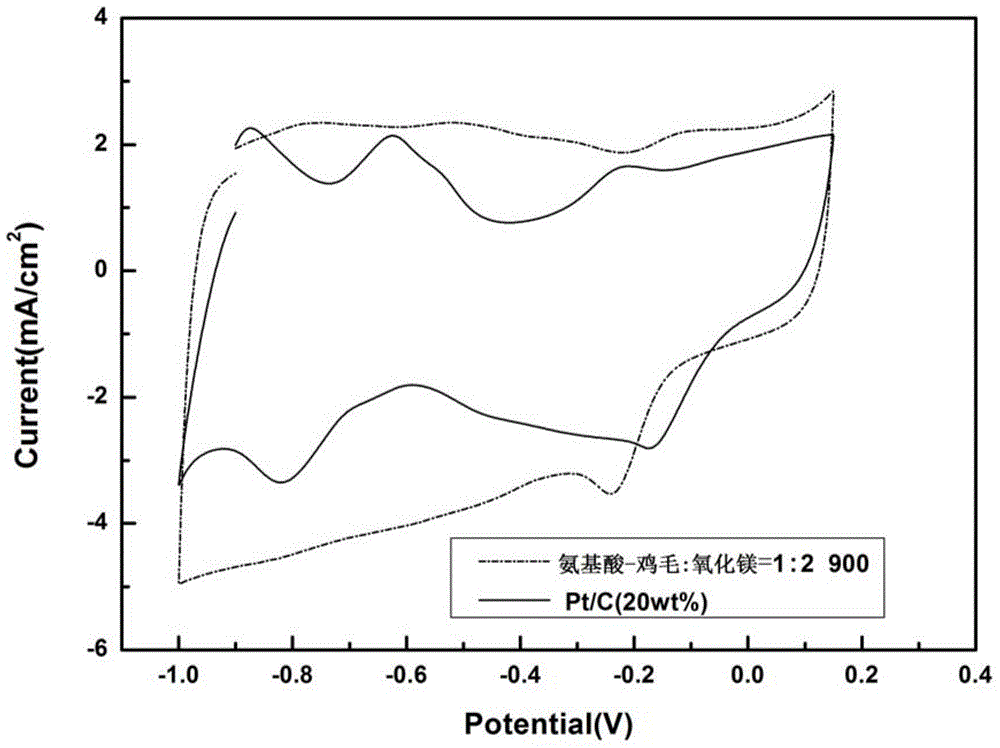

[0035]Weigh 0.4g of the above-mentioned amino acid powder and 0.2g of MgO (that is, the mass ratio of the precursor to the template is 1:0.5), pour both into a mortar, and grind them evenly. Place the mixture in a porcelain boat. The heating rate of the tube furnace was 5°C / min, from room temperature to 700°C, kept at 700°C for 3 hours, and finally cooled t...

Embodiment 2

[0037] Weigh 5g of pig hair into a beaker, pour 50ml of acetone into the ultrasonic for 20min, put it in an oven at 110°C for drying, cut the pig hair into pieces (about 5mm), pour the broken pig hair into the lining of the hydrothermal reaction kettle, add 55g of analytically pure ammonia water (mass ratio of hair to ammonia water is 1:11), hydrothermally reacted at 130°C for 5h. After the reaction kettle is cooled to room temperature, put the ammonia solution in which the amino acid is dissolved in an oven at 110°C until it is dried, and grind the obtained solid with a mortar to obtain solid powder amino acid.

[0038] Weigh 0.3g of the amino acid powder prepared in Example 2 and 0.45g of MgO, that is, the mass ratio of the precursor to the template is 1:1.5, and pour them into a mortar together, and grind them evenly. Place the mixture in a porcelain boat. The heating rate of the tube furnace was 5°C / min, from room temperature to 800°C, kept at 800°C for 2 hours, and final...

Embodiment 3

[0041] Weigh 6g of hair into a beaker, pour 50ml of acetone into the ultrasonic for 25min, put it in an oven at 110°C for drying, cut the hair into pieces (about 5mm), pour the broken hair into the lining of the hydrothermal reaction kettle, add 60g of analytical pure Ammonia water (mass ratio of hair to ammonia water is 1:10), hydrothermal reaction at 150°C for 3 hours. After the reaction kettle is cooled to room temperature, put the ammonia solution in which the amino acid is dissolved in an oven at 110°C until it is dried, and grind the obtained solid with a mortar to obtain solid powder amino acid.

[0042] Weigh 0.5g of the amino acid prepared in Example 3 and 0.5g of MgO, that is, the mass ratio of the precursor to the template is 1:1, and pour them into a mortar together, and grind them evenly. Place the mixture in a porcelain boat. The heating rate of the tube furnace was 5°C / min, from room temperature to 800°C, kept at 800°C for 2 hours, and finally cooled to room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peak current density | aaaaa | aaaaa |

| Peak current density | aaaaa | aaaaa |

| Peak current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com