High-activity iron-based low-temperature Fischer-Tropsch synthesis catalyst and preparation method thereof

A Fischer-Tropsch synthesis, iron catalyst technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, catalysts for physical/chemical processes, etc. , the preparation method is simple, the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Add iron powder and aluminum powder into the arc induction furnace with a weight ratio of 50:50, and then pass in argon gas after vacuuming, use electric current to stimulate arc heating, and evenly melt under the action of magnetic stirring, and then cool naturally or quickly Cool to room temperature, grind the iron-aluminum alloy to 100-200 mesh;

[0021] (2) Under the protection of argon, add 3 mL of 30% mass fraction potassium hydroxide solution into the stirring container, and wait until the temperature rises to 70 o At C, add 0.5 g of iron-aluminum alloy powder to the lye, and keep it for 1 h after the addition is complete. Then wash with deionized water to neutrality, then replace water with absolute ethanol, finally replace absolute ethanol with polyethylene glycol 200, and store the skeleton iron catalyst precursor therein;

[0022] (3) The framework iron catalyst precursor was dispersed in 20 mL polyethylene glycol 200, and then the catalyst and solvent w...

Embodiment 2

[0024] (1) Same as embodiment 1;

[0025] (2) Same as embodiment 1;

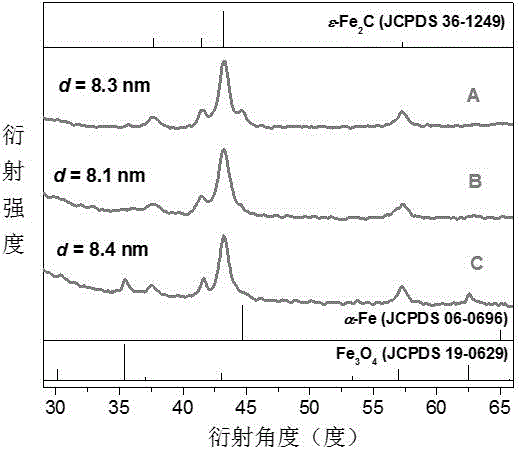

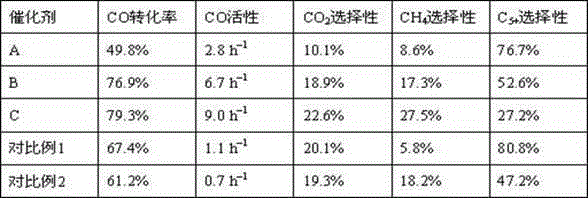

[0026] (3) The framework iron catalyst precursor was dispersed in 20 mL polyethylene glycol 200, and then the catalyst and solvent were transferred to a 50 mL autoclave. H at room temperature 2 The / CO = 2 synthetic gas is replaced and inflated to 3.0 MPa. The temperature of the Fischer-Tropsch synthesis reaction was set at 170 o C, the stirring speed is set to 800 rpm. Under the low-temperature Fischer-Tropsch synthesis reaction conditions, the precursor of the framework iron catalyst was simultaneously carbonized in situ. When the reaction pressure dropped to 3.0 MPa, the reaction was stopped and the autoclave was cooled to room temperature. The catalyst is named as B, and its performance evaluation time is 20 minutes, and the reaction results are shown in Table 1. The X-ray diffraction spectrum of gained catalyst in this example sees figure 1 ,show ε -Fe 2 C is the iron-containing active phase ...

Embodiment 3

[0028] (1) Same as embodiment 1;

[0029] (2) Same as embodiment 1;

[0030] (3) The framework iron catalyst precursor was dispersed in 20 mL polyethylene glycol 200, and then the catalyst and solvent were transferred to a 50 mL autoclave. H at room temperature 2 The / CO = 2 synthetic gas is replaced and inflated to 3.0 MPa. The temperature of the Fischer-Tropsch synthesis reaction was set at 200 oC, the stirring speed is set to 800 rpm. Under the low-temperature Fischer-Tropsch synthesis reaction conditions, the precursor of the framework iron catalyst was simultaneously carbonized in situ. When the reaction pressure dropped to 3.0 MPa, the reaction was stopped and the autoclave was cooled to room temperature. The catalyst is named as C, and its performance evaluation time is 15 minutes, and the reaction results are shown in Table 1. The X-ray diffraction spectrum of gained catalyst in this example sees figure 1 ,show ε -Fe 2 C is the iron-containing active phase i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com