Preparation method and application of porous silicon dioxide microsphere adsorbent

A porous silica and microsphere adsorption technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc. Promotion and application, etc., to achieve the effect of simple process, economical and practical, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

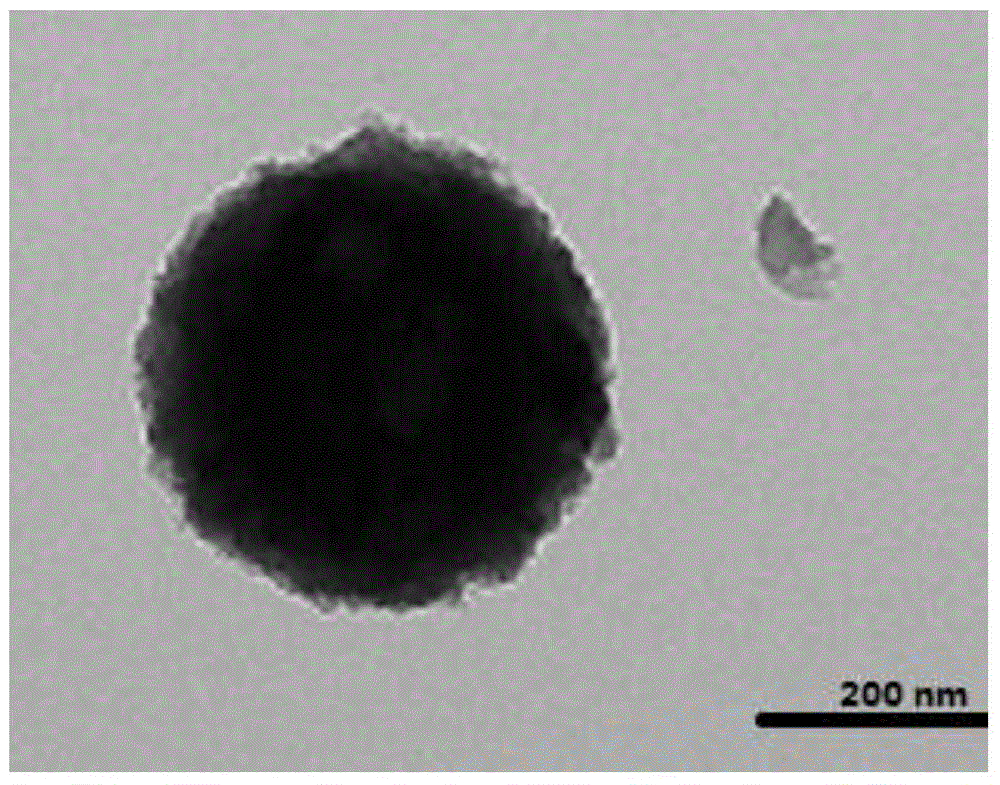

Image

Examples

preparation example Construction

[0023] A preparation method of porous silica microsphere adsorbent, comprising the following steps:

[0024] 1) Add ammonia water to isopropanol and deionized water to prepare a mixed solution of ammonia water-isopropanol-deionized water, then add ethyl orthosilicate to the above mixed solution, and stir at room temperature for 1.5-2.5 hours;

[0025] The volume ratio of the ethyl orthosilicate, ammonia water, isopropanol and deionized water is 1:0.8-1.2:18-22:3-5;

[0026] 2) Centrifuge the above-mentioned mixed solution after stirring for 4-6 min at a rotating speed of 8000-10000 r / min, discard the supernatant to obtain a precipitate, and then wash the above-mentioned precipitate with water for 2-4 times to obtain silica microspheres ;

[0027] 3) The above-mentioned silica microspheres are dispersed in water, and the add-on of the water is 28-32 times of ethyl orthosilicate, and then soluble polyvinylpyrrolidone is added, and the mol ratio of the polyvinylpyrrolidone and s...

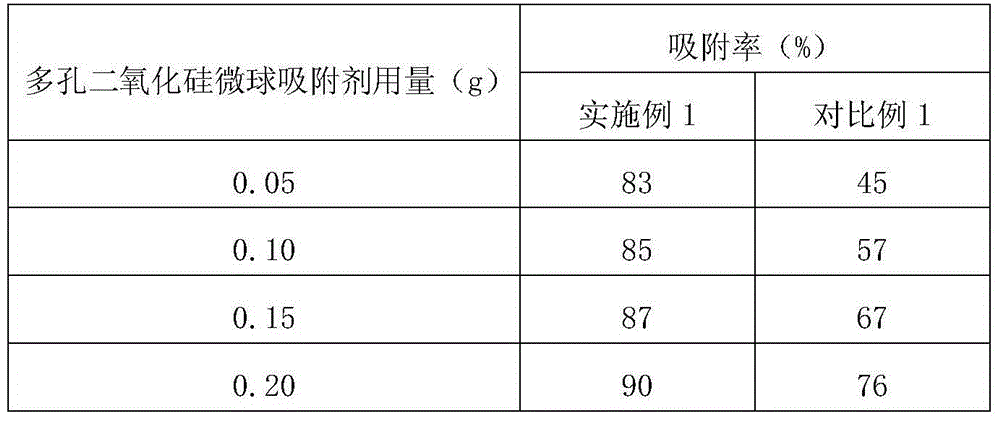

Embodiment 1

[0035] A preparation method of porous silica microsphere adsorbent, comprising the following steps:

[0036] 1) Add 10 mL of ammonia water to 200 mL of isopropanol and 40 mL of deionized water to prepare a mixed solution of ammonia water-isopropanol-deionized water, then add 10 mL of ethyl orthosilicate to the above mixed solution, and stir at room temperature for 2 hours;

[0037] 2) Centrifuge the above-mentioned mixed solution at a rotating speed of 9000 r / min for 5 min, discard the supernatant to obtain a precipitate, then wash the above-mentioned precipitate 3 times with water for 5 min each time to obtain silicon dioxide Microspheres;

[0038] 3) Disperse the above-mentioned silica microspheres in 300 mL of water, add soluble polyvinylpyrrolidone K30, the molar ratio of polyvinylpyrrolidone to silica is 10:1, and the mixed solution is cooled to room temperature after being condensed by water circulation for 3 hours;

[0039] 4) Add 0.15g / mL NaOH solution to the above co...

Embodiment 2

[0058] A preparation method of porous silica microsphere adsorbent, comprising the following steps:

[0059] 1) Add 8 mL of ammonia water to 180 mL of isopropanol and 30 mL of deionized water to prepare a mixed solution of ammonia water-isopropanol-deionized water, then add 10 mL of ethyl orthosilicate to the above mixed solution, and stir at room temperature for 1.5 h ;

[0060] 2) Centrifuge the above-mentioned mixed solution at a rotating speed of 8000 r / min for 6 min, discard the supernatant to obtain a precipitate, and then wash the above-mentioned precipitate 4 times with water for 4 min each time to obtain silicon dioxide solid;

[0061] 3) Disperse the above-mentioned silica microspheres in 280 mL of water, add a certain amount of soluble polyvinylpyrrolidone K 30, the molar ratio of polyvinylpyrrolidone to silica is 12:1, and after the mixed solution is condensed by water circulation for 3.5h, cooled to room temperature;

[0062] 4) Add 0.15g / mL NaOH solution to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com