Fluorescence analysis method for element content of iron-based alloy

An iron-based alloy, element content technology, applied in fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of long analysis period, short analysis period, cumbersome operation, etc., achieve complete and accurate theoretical strength, shorten analysis period, and improve detection. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A method for fluorescence analysis of element content in iron-based alloys, comprising the steps of:

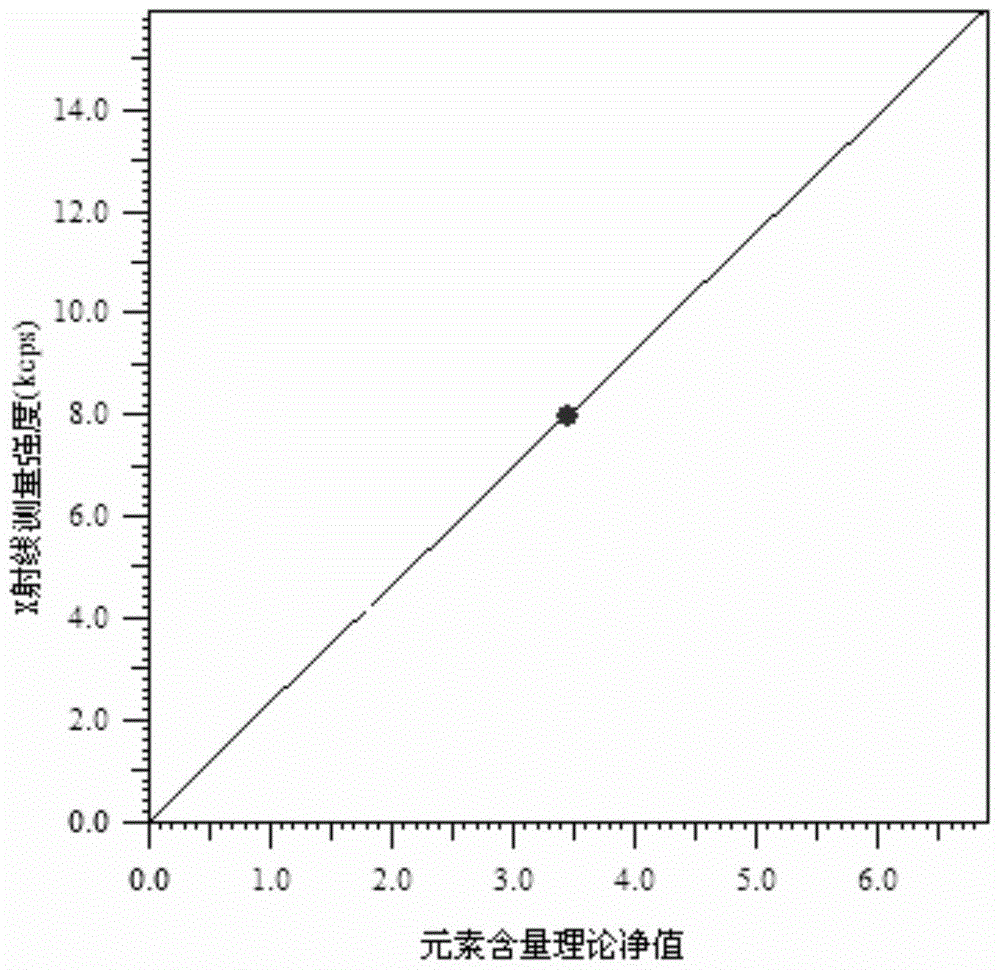

[0023] (1) Measure the iron-based alloy standard sample. The fluorescence spectrometer used is Shimadzu XRF-1800 sequential spectrometer. Utilize the fluorescence spectrometer to measure the existing various iron-based alloy standard samples, and use the basic parameters of the fluorescence spectrometer FP working software A comprehensive calibration curve for these iron-based alloys was drawn;

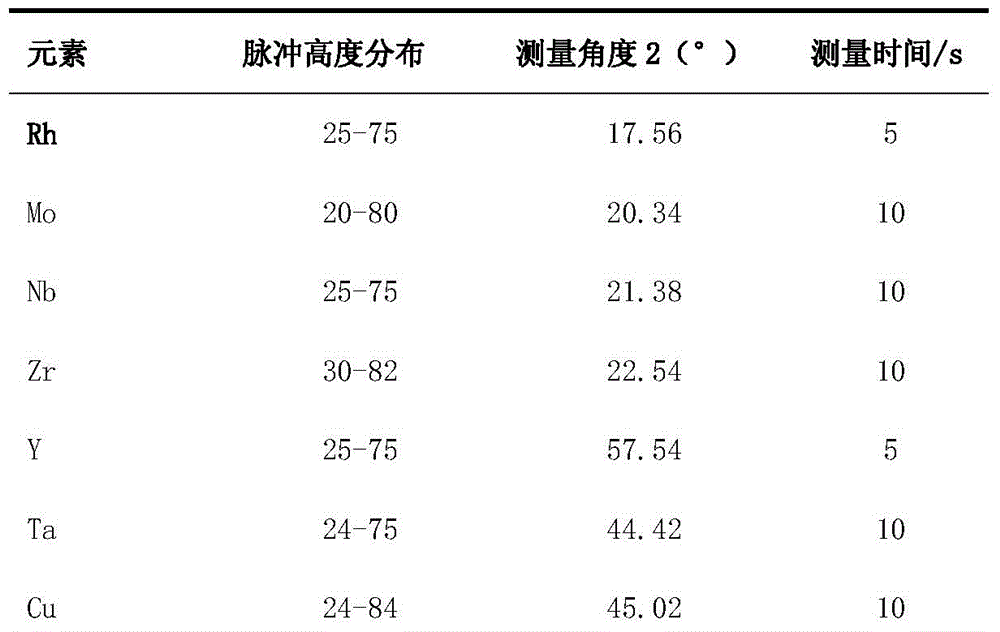

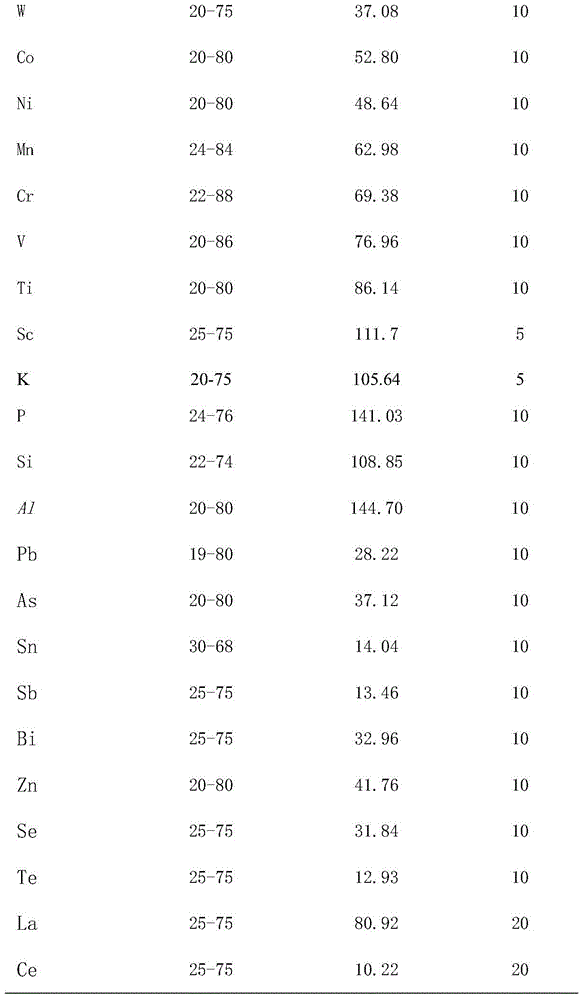

[0024] (2) Compare the comprehensive standard curve to determine the best measurement parameters of the fluorescence spectrometer for various elements of the iron-based alloy, including excitation angle, pulse range, excitation voltage and excitation current, etc., its mask diameter is 20mm, titanium and atomic Elements whose ordinal number is greater than it select voltage 60kV, current 55mA, scandium and elements whose atomic number is less than it select voltage 30kV, curre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com