Construction method for antistatic epoxy floor level

An anti-static ring and construction method technology, applied in epoxy resin coatings, conductive coatings, coatings, etc., can solve the problems of complex operation, high cost, difficult maintenance, etc., and achieve good electrical conductivity, low cost, and save operation. effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A construction method of antistatic epoxy floor, comprising the following steps:

[0039] (1) Grinding: adjust the flatness of the concrete foundation by adding water to grind;

[0040] (2) Inspection: Through on-site investigation and inspection of the concrete base, master the overall situation, surface firmness, pollution and moisture content of the concrete base;

[0041] (3) Cleaning: Use a broom to clean the surface of the concrete base, use a deep cleaner to remove surface stains, and rinse with low-pressure water;

[0042] (4) Surface treatment: remove cement foam, curing agent, and mold release agent, and use rough cutting, milling, sandblasting, needle gun, high-pressure water pump or steel shot according to the surface of the floor to be painted and different coating systems Sand blasting to ensure the adhesion between the concrete base and the floor coating material layer;

[0043] (5) Repair: Remove the weak or damaged concrete surface, and then use epoxy...

Embodiment 2

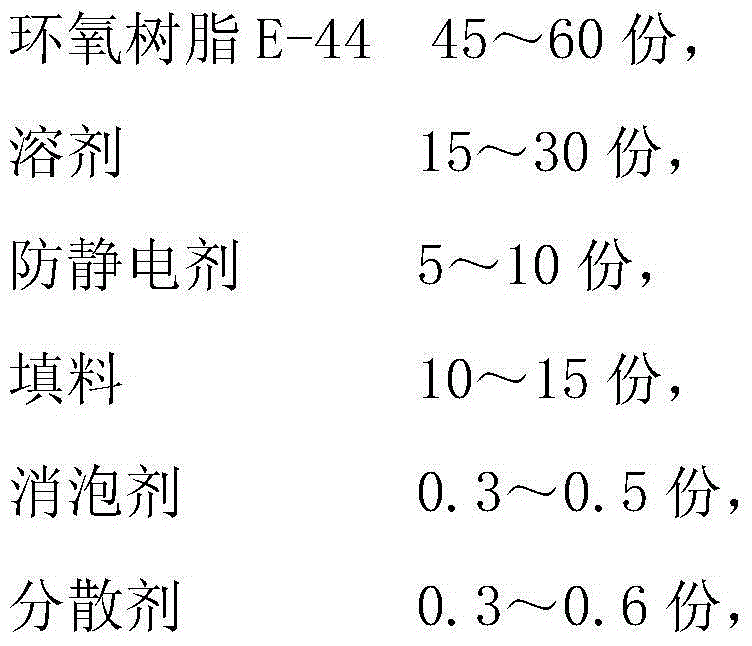

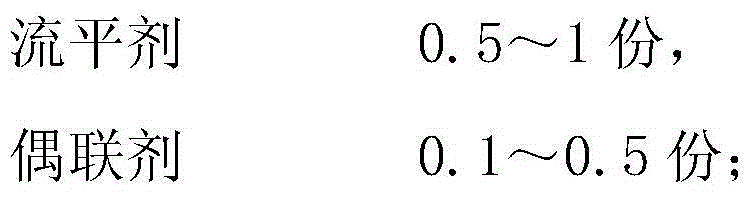

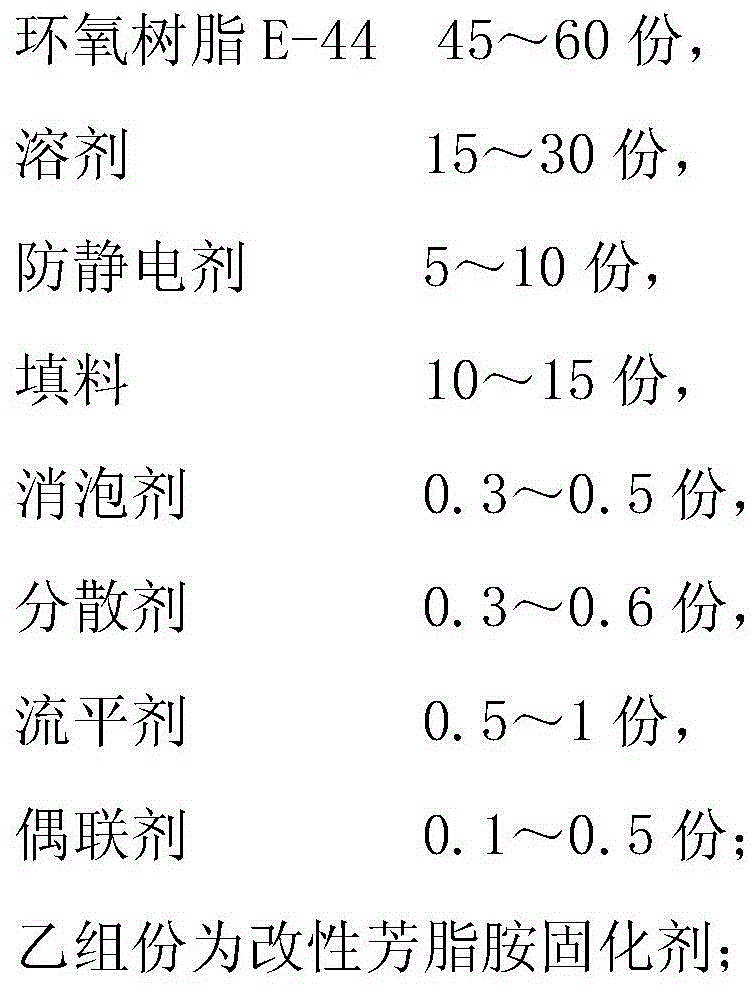

[0055] What is different from Example 1 is that the weight portion of the first component of the antistatic conductive epoxy primer in the step (9) consists of: 60 parts of epoxy resin E-44, 23.8 parts of solvent, 5 parts of antistatic agent, talcum 10 parts of powder, 0.3 parts of polysiloxane, 0.3 parts of triethylhexyl phosphoric acid, 0.5 parts of modified polyacrylate, and 0.1 part of silane coupling agent.

Embodiment 3

[0057] What differs from previous embodiment is the composition by weight of the first component of the antistatic conduction epoxy primer in the step (9): 59.8 parts of epoxy resin E-44, 15 parts of solvents, 9 parts of antistatic agents, talcum 14 parts of powder, 0.4 parts of polysiloxane, 0.5 parts of triethylhexyl phosphoric acid, 0.9 parts of modified polyacrylate, and 0.4 parts of silane coupling agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com