Ultraviolet crosslinked polyethylene heat shrinkage package film and preparation method thereof

A technology of cross-linked polyethylene and polyethylene film, which is applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of high energy consumption and high cross-linking cost, and achieve cross-linking cost reduction, convenient cross-linking operation, and good The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

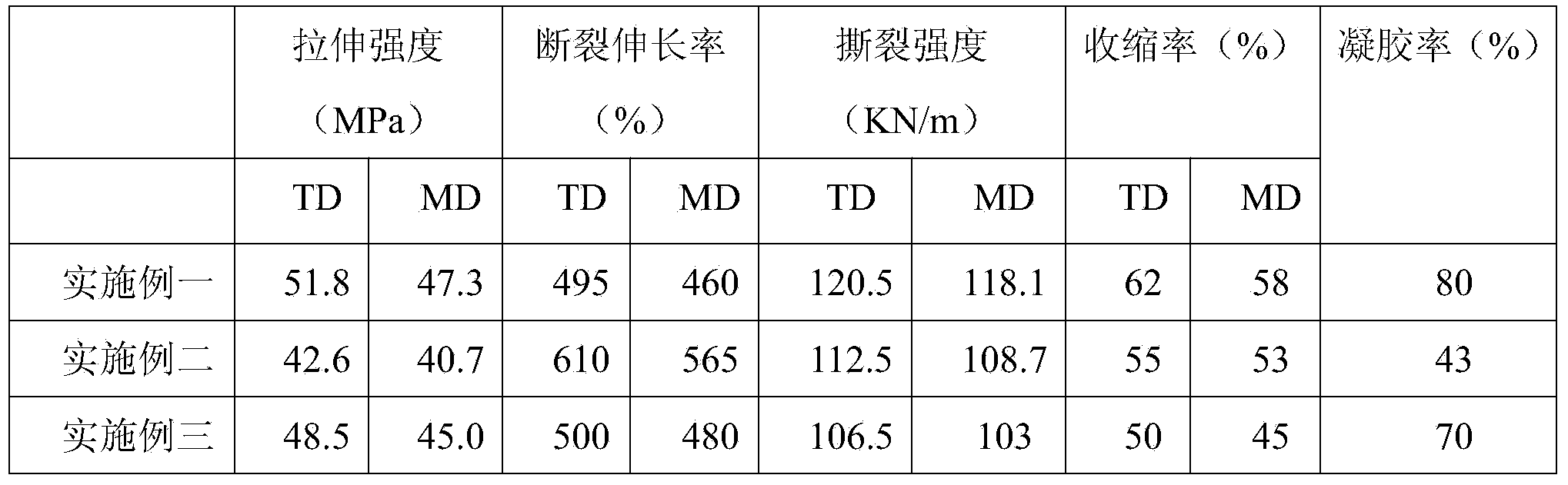

Examples

specific Embodiment approach 1

[0017] Specific embodiment 1: In this embodiment, an ultraviolet light cross-linked polyethylene heat shrinkable packaging film is formed by superposing three layers of polyethylene film; the polyethylene film is composed of 20 to 70 parts by weight of linear low density polyethylene, 10-30 parts of low-density polyethylene, 10-30 parts of metallocene polyethylene and 10-20 parts of ultraviolet photoinitiator masterbatch; wherein the ultraviolet photoinitiator masterbatch is dried from 100 parts by weight The linear low-density polyethylene, 0.04-1.6 parts of photoinitiator, 2-16 parts of auxiliary crosslinking agent and 0.02-0.8 parts of antioxidant.

[0018] The ultraviolet light cross-linked polyethylene heat shrinkable packaging film of this embodiment does not require special and complex cross-linking equipment, which reduces the cost of cross-linking. Through cross-linking, its heat resistance, environmental resistance, and chemical resistance are improved, and it has very ...

specific Embodiment approach 2

[0021] Specific embodiment two: this embodiment is different from specific embodiment one in that: the photoinitiator is benzoin dimethyl ether, dialkoxy acetophenone, anthrone, benzophenone and benzophenone derivatives One or a mixture of several of them, when it is a mixture, mix at any ratio. Others are the same as the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: this embodiment is different from specific embodiment one or two in that: the co-crosslinking agent is triallyl isocyanurate, acrylate, trimethacrylate, tricarboxymethyl propyl, double Ethylene methacrylate, trimethyl diisocyanate, polycarbodiimide and polypropylene glycol glycidyl ether, or a mixture of several of them, are mixed at any ratio when they are mixtures. Others are the same as the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com