Magnetic levitation single shaft direct drive compressor

A magnetic levitation and compressor technology, applied in the direction of magnetic bearings, bearings, shafts and bearings, etc., can solve the problems of large vibration and noise, high frictional heat, low transmission efficiency, etc., to reduce vibration and noise, eliminate friction and wear, and operate efficiently Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

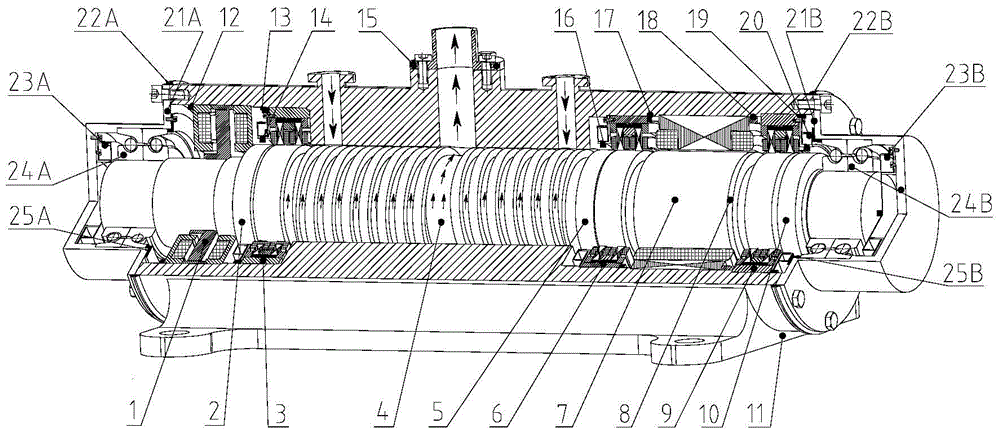

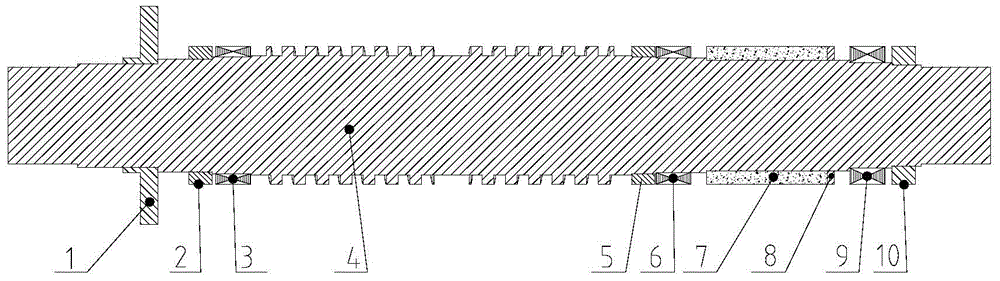

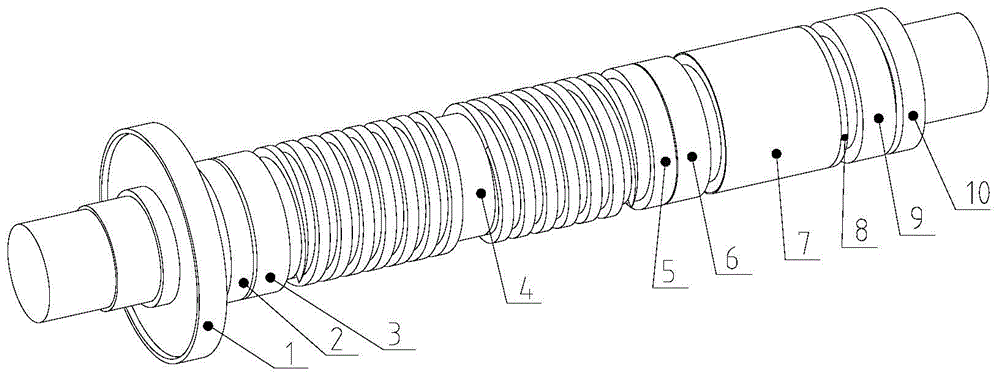

[0035] like figure 1 As shown, the maglev single-shaft direct-drive compressor is mainly composed of two parts: the rotor system and the stator system. The rotor system mainly includes: axial magnetic bearing 1 rotor, left radial displacement sensor detection ring 2, left radial magnetic bearing 3 rotor , screw shaft 4, middle radial displacement sensor detection ring 5, middle radial magnetic bearing 6 rotor, motor 7 rotor, pressure ring 8, right radial magnetic bearing 9 rotor and right radial displacement sensor detection ring 10; the stator system mainly Including: axial magnetic bearing 1 stator, left radial magnetic bearing 3 stators, middle radial magnetic bearing 6 stators, motor 7 stators, right radial magnetic bearing 9 stators, frame 11, axial magnetic bearing stator self-locking nut 12 , Left radial magnetic bearing stator self-locking nut 13, left radial displacement sensor 14, oil outlet joint 15, middle radial magnetic bearing stator self-locking nut 16, middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com