Red fluorescent powder and preparation method thereof

A technology for red phosphor powder and raw materials, applied in the field of red phosphor powder and its preparation, can solve the problems of poor color rendering, low luminous efficiency, lack of red light, etc., and achieve the effect of high color purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

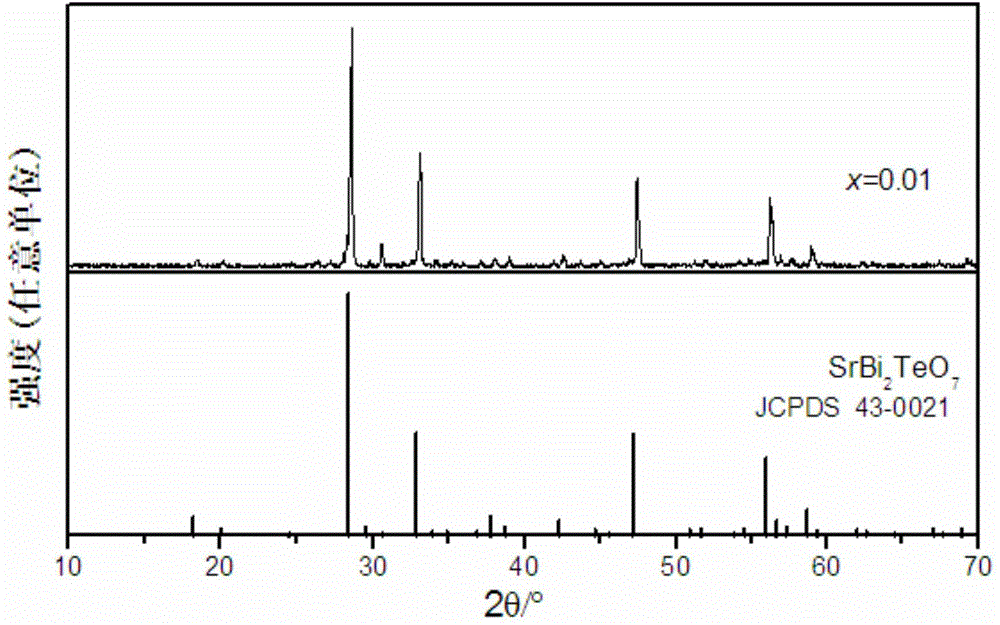

[0024] According to the chemical formula SrBi 1.98 Eu 0.02 TeO 7 The stoichiometric ratio of each element in the formula is weighed separately: strontium carbonate [SrCO 3 ] 0.1845g, bismuth oxide [Bi 2 o 3 ] 0.5766g, tellurium dioxide [TeO 2 ] 0.1995g, europium oxide [Eu 2 o 3 ] 0.0044g, grinding to mix the materials evenly, sintering at 800°C for 2 hours in an air atmosphere, cooling to room temperature, taking out the sample and grinding, and finally the product was obtained. The X-ray diffraction pattern of the phosphor is shown in figure 1 , the position of the diffraction peak is consistent with the standard card #43-0021, indicating that doping has not changed the SrBi 2 TeO 7 The crystalline phase, obtained SrBi 1.98 Eu 0.02 TeO 7 pure phase compounds.

Embodiment 2

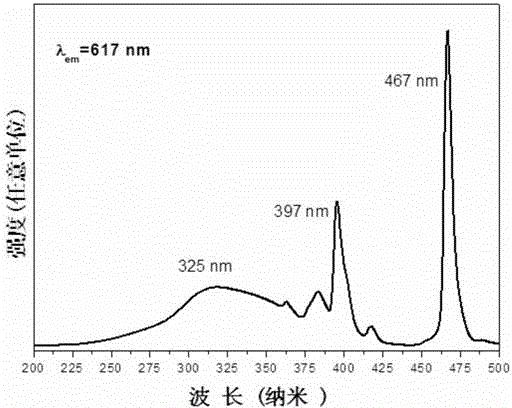

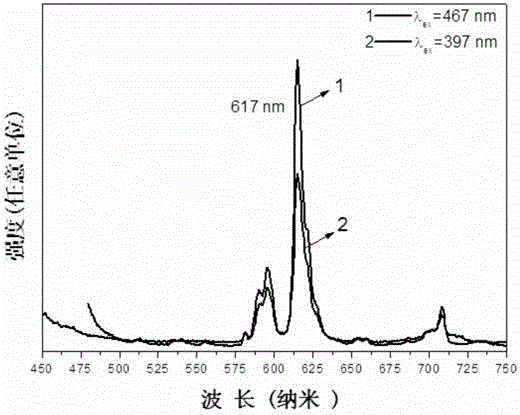

[0026] According to the chemical formula SrBi 1.98 Eu 0.02 TeO 7 The stoichiometric ratio of each element in the formula is weighed separately: strontium carbonate [SrCO 3 ] 0.1845g, bismuth oxide [Bi 2 o 3 ] 0.5766g, tellurium dioxide [TeO 2 ] 0.1995g, europium oxide [Eu 2 o 3 ] 0.0044g, grinding to mix the materials evenly, sintering at 900°C for 8 hours in an air atmosphere, cooling to room temperature, taking out the sample and grinding, and finally the product was obtained. Determination of room temperature excitation spectrum of phosphor see figure 2 . Under the monitoring of 617nm, the sample exhibits a broadband absorption at 300-400nm, and a strong absorption at 397nm and 467nm, indicating that the phosphor is in good agreement with the emission wavelengths of the near-ultraviolet chips and blue LED chips used in current LED devices , can realize high-efficiency excitation of near-ultraviolet chips and blue-light chips, and is an ideal phosphor for near-ultr...

Embodiment 3

[0028] According to the chemical formula SrBi 0.2 Eu 1.8 TeO 7 The stoichiometric ratio of each element in the formula is weighed separately: strontium carbonate [SrCO 3 ] 0.1845g, bismuth oxide [Bi 2 o 3 ] 0.0582g, tellurium dioxide [TeO 2 ] 0.1995g, europium oxide [Eu 2 o 3 ] 0.3959g, grinding to mix the materials evenly, sintering at 850°C for 2 hours in an air atmosphere, cooling to room temperature, taking out the sample and grinding, and finally the product was obtained. The X-ray diffraction pattern of the phosphor is shown in image 3 , the position of the diffraction peak is consistent with the standard card #43-0021, indicating the high concentration of Eu 3+ The doping did not change the SrBi 2 TeO 7 The crystal phase of SrBi is obtained 0.2 Eu 1.8 TeO 7 pure phase compounds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com