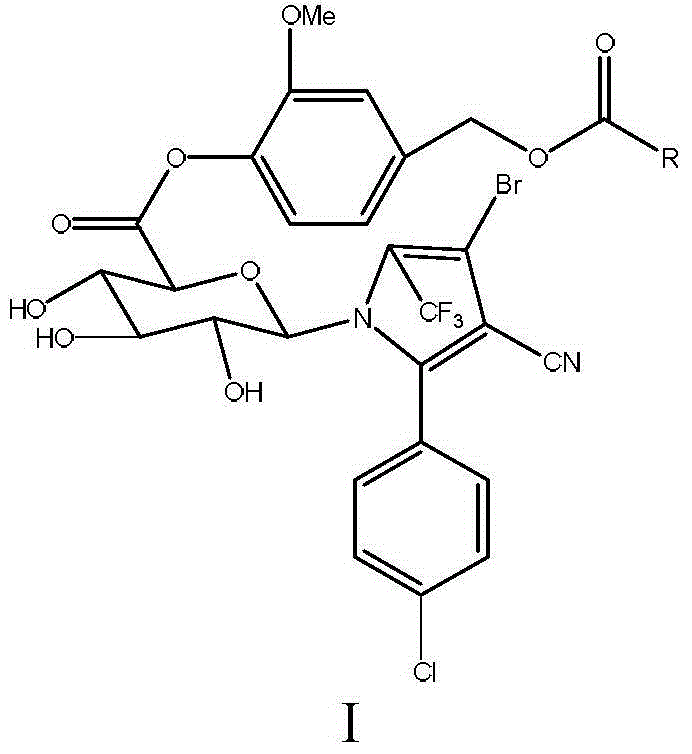

Capsaicin-like compound and preparation method and use thereof

A technology for capsaicin and compounds, which is applied to capsaicinoid compounds and the fields of their preparation and application, can solve problems such as environmental pollution, and achieve the effects of long service life, good antifouling effect, and avoiding adhesion and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

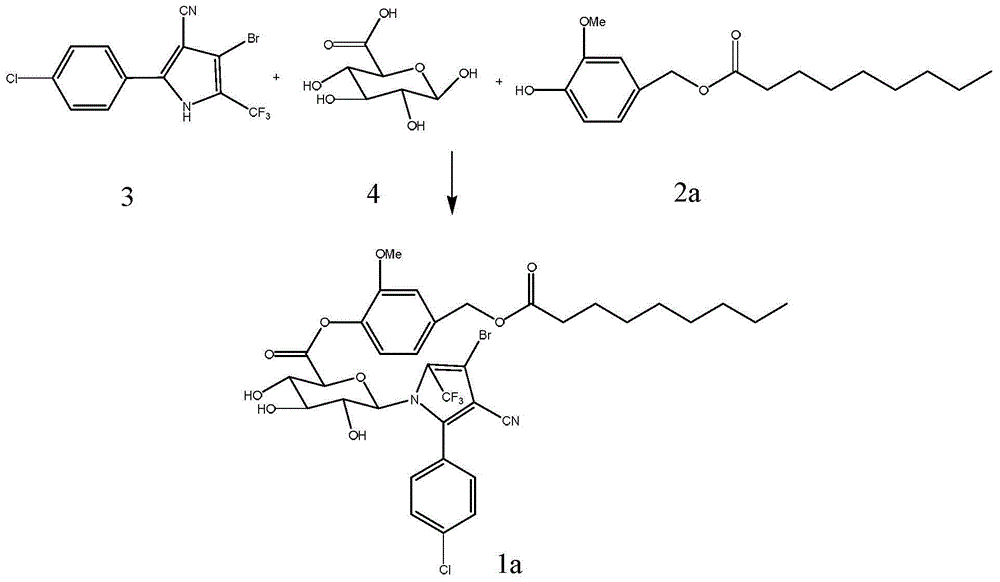

[0025] Capsaicinoid 1a (C 35 h 37 N 2 o 9 f 3 ClBr) synthesis:

[0026]

[0027] In a 500ml three-necked reaction flask equipped with a thermometer, a stirrer, and a reflux condenser device, add 35.0g (0.1mol) of 4-bromo-2-(4-chlorophenyl)-5-trifluoromethylpyrrole-3 nitrile , 38.8g (0.2mol) glucuronic acid, 29.4g (0.1mol) capsaicin ester (compound 2a), 250ml toluene, after stirring and dissolving, add 17.2g (0.1mol) p-toluenesulfonic acid, reflux reaction 6 hours, Wash with saturated sodium bicarbonate solution to pH = 7-8, stand still, separate the liquid, wash with 100ml distilled water, stand still, separate the liquid, dry over anhydrous sodium sulfate, filter, and distill off the solvent to obtain the crude product of capsaicinoid compound 1a , was dissolved in 160ml of cyclohexane, and recrystallized at 5°C to obtain 59.9g of white solid powdered capsaicinoid compound 1a with a yield of 74.9% and a purity of 96.8% (HPLC). 1a 1 H NMR (DMSO / 500MHz): 7.42(d,1H,Ar-...

Embodiment 2

[0029] Capsaicinoid 1b (C 36 h 37 N 2 o 9 f 3 ClBr) synthesis:

[0030]

[0031] In a 500ml three-necked reaction flask equipped with a thermometer, a stirrer, and a reflux condenser device, add 35.0g (0.1mol) of 4-bromo-2-(4-chlorophenyl)-5-trifluoromethylpyrrole-3 nitrile (compound 3), 77.6g (0.4mol) glucuronic acid (compound 4), 30.6g (0.1mol) capsaicin ester (compound 2b), 250ml xylene, after stirring and dissolving, add 15.8g (0.1mol) benzene Sulfonic acid, reflux reaction for 6 hours, washed with saturated sodium bicarbonate solution to pH = 7-8, let stand, separate liquid, wash with 100ml distilled water, stand still, separate liquid, dry with anhydrous sodium sulfate, filter, distill off the solvent, The capsaicinoid compound 1b crude product was obtained, which was dissolved in 160ml of cyclohexane and recrystallized at 5°C to obtain 58.1g of white solid powder capsaicinoid compound 1b with a yield of 71.5% and a purity of 97.5% (HPLC) . 1b 1H NMR (DMSO / 500...

Embodiment 3

[0032] Embodiment 3 antifouling performance test

[0033] The 80.0g concentration is 30% zinc acrylate resin solution (organic solvent is xylene), 5.0g rosin, 10.0g titanium dioxide, 5g capsaicinoid compound 1a mixture shakes 2.0h in a paint shaker that contains glass beads, Then filter with a 100-mesh filter to prepare the antifouling paint A1.

[0034] 50.0g concentration is 50% acrylic resin solution (organic solvent is toluene), 10.0g dibutyl phthalate, 10.0g silicon dioxide, 30g capsaicinoid compound 1a mixture are shaken in a paint containing glass beads Shake in a container for 2.0 hours, and then filter with a 100-mesh filter to prepare antifouling paint A2.

[0035] 30.0g concentration is 80% acrylic resin solution (organic solvent is butyl acetate), 20.0g chlorinated paraffin, 20.0g talcum powder, 20.0g capsaicinoid compound 1b mixture in a paint shaker containing glass beads Shake for 2.0 hours, and then filter with a 100-mesh filter to prepare antifouling paint A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com