Micro-channel preparation method of nano silicon dioxide with uniform particle size

A nano-silicon dioxide and silicon dioxide technology, applied in the direction of silicon dioxide, silicon oxide, nanotechnology for materials and surface science, etc., can solve the problems of difficult particle size and uneven particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

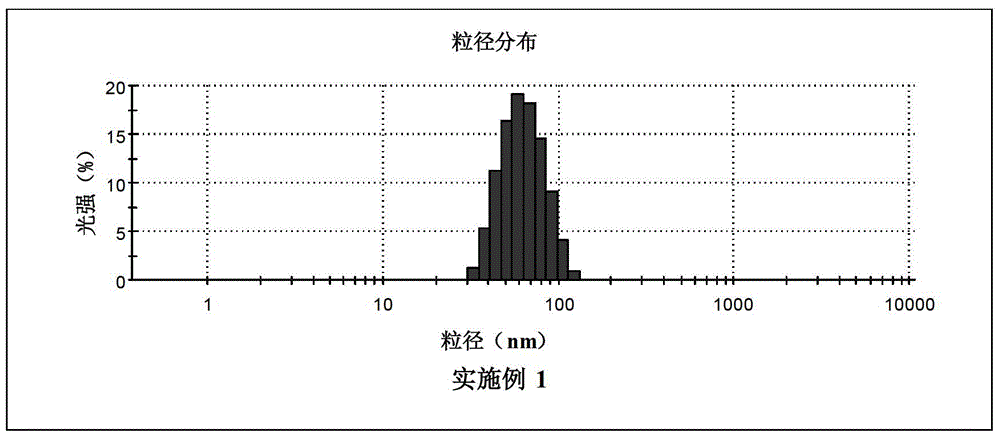

Embodiment 1

[0030] Add 178ml of tetraethyl orthosilicate to 222ml of ethanol to make solution A, add 110ml of ammonia water and 45ml of water to 245ml of ethanol to make solution B; liquid A and liquid B enter the inlet at a flow rate of 2.055ml / min respectively, and the form is T-shaped , length is 60mm, internal diameter is to carry out reaction in the microchannel reactor of 0.68mm (microchannel reactor adopts laser drilling (inner diameter is 0.5mm), adopts the method for enlarging hole to prepare by wire cutting method then); Then feed liquid into the reactor for aging reaction. The reaction temperature and aging temperature were 80°C. Finally, a silica nanoparticle solution was obtained. The particle size and PDI value of the silica nanoparticles in the solution can be directly measured by a Malvern ZS90 particle size analyzer, and the results are shown in Table 1.

Embodiment 2

[0036] Carry out the same steps as Example 1, change the volume flow rate of liquid to be 1.233ml / min, evaluate in the same way as Example 1, the results are in Table 1.

Embodiment 3

[0038] Carry out the same steps as in Example 1, change the volume flow rate of the liquid to 0.822ml / min, evaluate in the same manner as in Example 1, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com