A light-cured heavy-duty anti-corrosion coil and its preparation method

A light-curing, heavy-duty anti-corrosion technology, applied in chemical instruments and methods, protective equipment, anti-corrosion coatings, etc., can solve problems such as low construction speed and efficiency, waste pollution, impact on the environment and safety, and reduce the construction quality of human factors Inconsistency, good anti-corrosion performance, shortening the construction period of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0124] Embodiment 1 manufactures light-cured heavy-duty anti-corrosion coil

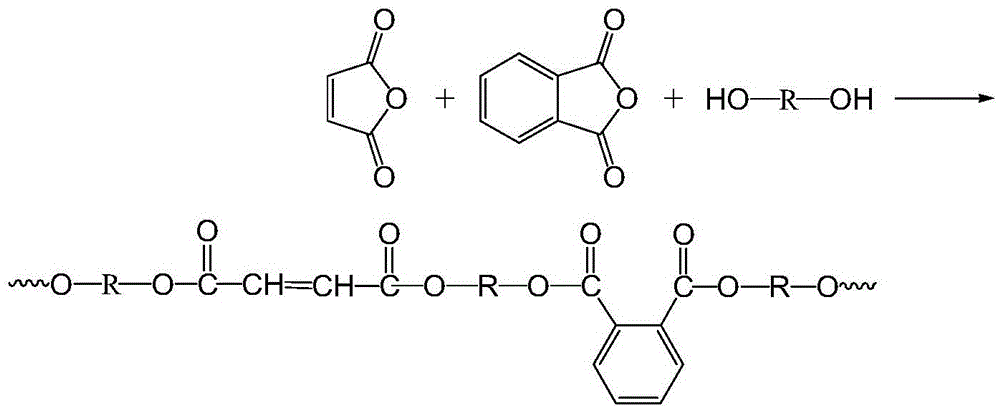

[0125] 1. Preparation of resin paste base material

[0126] Weigh each raw material according to the composition in Table 1 and mix them uniformly to obtain five kinds of resin paste base materials A, B, C, D, and E.

[0127] Among them, 3301# bisphenol A corrosion-resistant resin, Jinan City Resin Synthetic Material Factory;

[0128] 197E# Epoxy modified corrosion-resistant resin, Jinan Lvzhou Composite Material Co., Ltd.;

[0129] LDV3201# isocyanate modified acrylic vinyl resin, Ningbo Dacheng New Materials Co., Ltd.;

[0130] VER-1# phenolic epoxy vinyl ester resin, Jinan Oasis Composite Materials Co., Ltd.;

[0131] LDV158# epoxy modified vinyl resin, Ningbo Dacheng New Materials Co., Ltd.

[0132] Table 1

[0133]

[0134] 2. Processing light-cured heavy-duty anti-corrosion coils

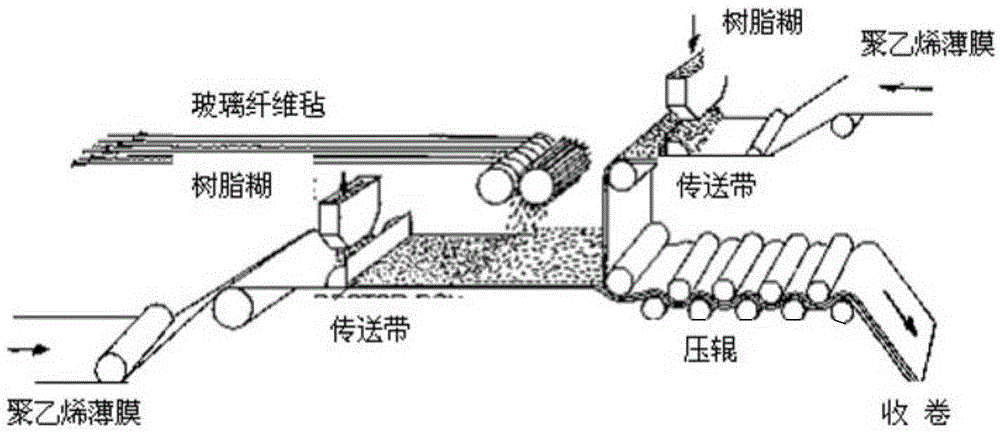

[0135] use as figure 1 The shown device and production process, by mass ratio 60-70% resin paste base ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com