A UV curable sheet for external heat preservation and cold preservation of pipelines

A technology of ultraviolet light and external thermal insulation, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of affecting the environment and safety, low construction speed and efficiency, waste pollution, etc., to achieve self-weight Light, good weather resistance, good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

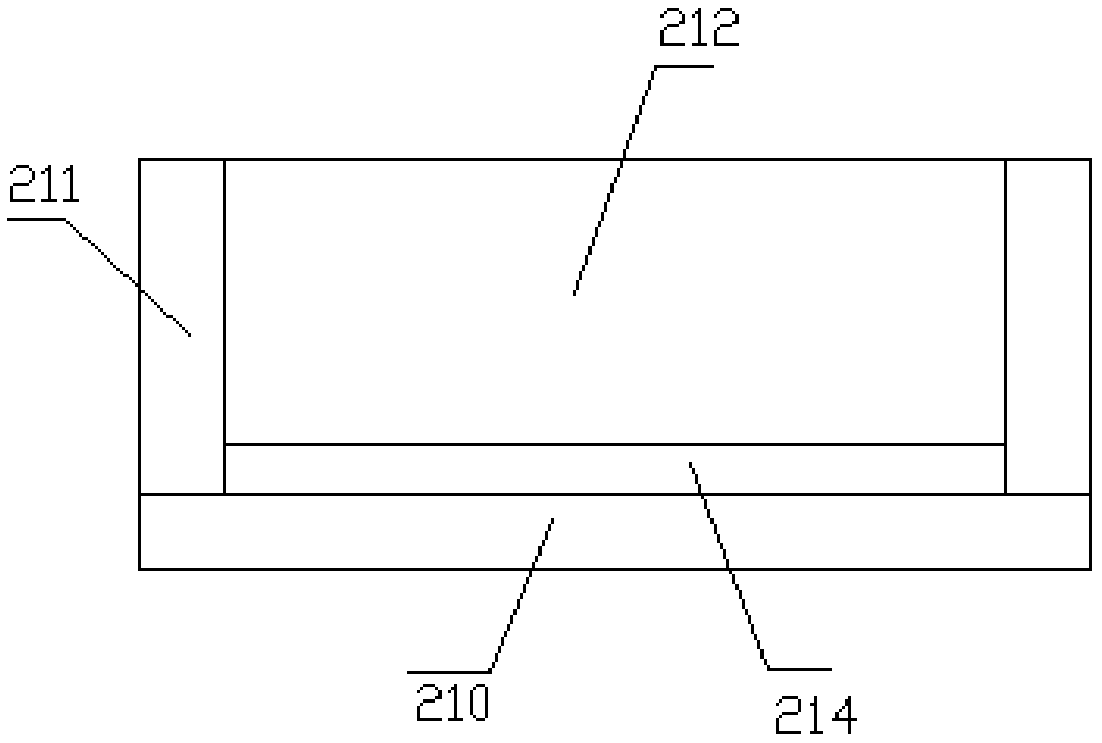

[0043] An ultraviolet curable sheet for external thermal insulation and cold preservation of pipelines, which includes an upper carrier film, an outer epoxy vinyl ester base layer, chopped glass fibers, a glass fiber thin felt, and an inner epoxy vinyl ester base layer in sequence from top to bottom and a lower carrier film, the upper carrier film is a black PET film, and the lower carrier film is a transparent FPC carrier film;

[0044] The composition of the outer epoxy vinyl ester base layer and the inner epoxy vinyl ester base layer is as follows in parts by weight:

[0045] 20 parts of epoxy vinyl ester resin, 15 parts of unsaturated polyester resin, 0.18 parts of ultraviolet curing agent A, 0.3 parts of ultraviolet curing agent B, 0.6 parts of filler sizing agent, 0.38 parts of glass fiber sizing agent, and 0.19 parts of ultraviolet light stabilizer parts, 0.32 parts of UV stabilizer B, 18 parts of aluminum hydroxide A, 42 parts of aluminum hydroxide B, 0.15 parts of mag...

Embodiment 2

[0068] An ultraviolet curable sheet for external thermal insulation and cold preservation of pipelines, which includes an upper carrier film, an outer epoxy vinyl ester base layer, chopped glass fibers, a glass fiber thin felt, and an inner epoxy vinyl ester base layer in sequence from top to bottom and a lower carrier film, the upper carrier film is a black PET film, and the lower carrier film is a transparent FPC carrier film;

[0069] The composition of the outer epoxy vinyl ester base layer and the inner epoxy vinyl ester base layer is as follows in parts by weight:

[0070] 17 parts of epoxy vinyl ester resin, 12 parts of unsaturated polyester resin, 0.12 parts of UV curing agent A, 0.25 parts of UV curing agent B, 0.35 parts of filler sizing agent, 0.25 parts of glass fiber sizing agent, 0.18 parts of UV light stabilizer parts, 0.22 parts of UV stabilizer B, 14 parts of aluminum hydroxide A, 38 parts of aluminum hydroxide B, 0.10 parts of magnesium oxide A, 0.10 parts of...

Embodiment 3

[0093] An ultraviolet curable sheet for external thermal insulation and cold preservation of pipelines, which includes an upper carrier film, an outer epoxy vinyl ester base layer, chopped glass fibers, a glass fiber thin felt, and an inner epoxy vinyl ester base layer in sequence from top to bottom and a lower carrier film, the upper carrier film is a black PET film, and the lower carrier film is a transparent FPC carrier film;

[0094] The composition of the outer epoxy vinyl ester base layer and the inner epoxy vinyl ester base layer is as follows in parts by weight:

[0095] 24 parts of epoxy vinyl ester resin, 18 parts of unsaturated polyester resin, 0.25 parts of UV curing agent A, 0.40 parts of UV curing agent B, 1.00 parts of filler sizing agent, 0.50 parts of glass fiber sizing agent, and 0.20 parts of UV light stabilizer parts, 0.40 parts of UV stabilizer B, 22 parts of aluminum hydroxide A, 50 parts of aluminum hydroxide B, 0.20 parts of magnesium oxide A, 0.12 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com