Heat insulation and cold insulation prefabricated pipeline shell for protecting pipeline from outside

A technology of external protection and tube shell, which is applied in the field of prefabricated tube shell for external protection of pipelines, which can solve problems such as short protection period, hidden dangers, and safety, and achieve good thermal insulation performance, cost saving, and energy efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A heat-preserving and cold-preserving pipe outer protective prefabricated shell, the preparation method of which is as follows:

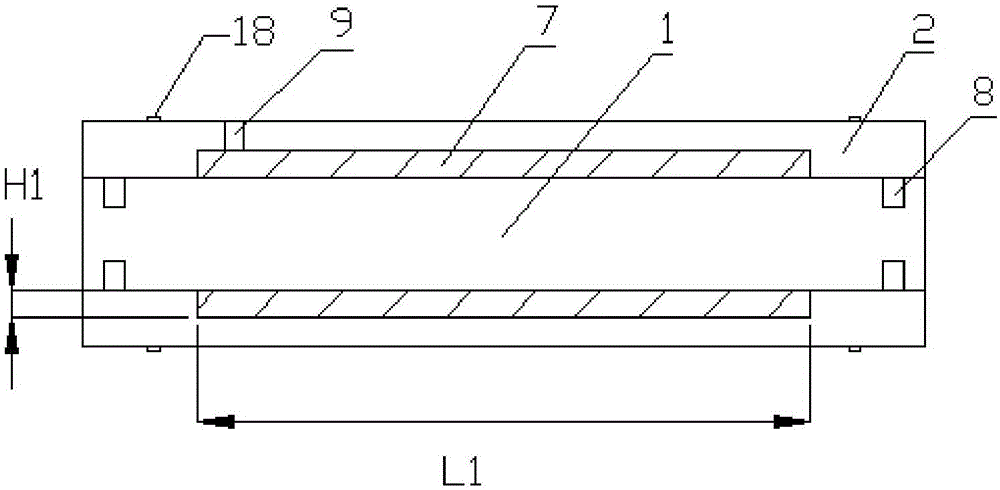

[0030] (1) One set of prefabricated transparent molds: the transparent mold includes an inner film cover 1, a first outer mold cover 2 and a second outer mold cover 3, the inner film cover is a cylindrical structure, and the inner film cover is provided with two The first draw-in groove 4, the first draw-in groove is respectively arranged at the two ends of the inner film cover; the first outer die cover includes the first upper die cover 5 and the first lower die cover 6 of the semi-circular structure, the first The upper mold casing and the first lower mold casing are closed to each other so that the first outer mold casing has a cylindrical structure as a whole. The first channel is formed in the first outer mold casing. Glue bearing groove 7, the inner wall of the first channel is also provided with two circles of first convex strips 8, t...

Embodiment 2

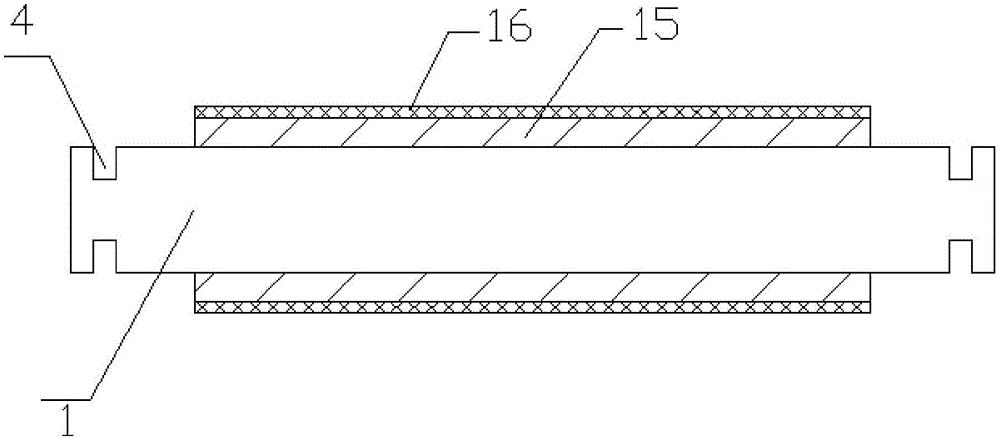

[0053] A heat-preserving and cold-preserving pipe outer protective prefabricated shell, the preparation method of which is as follows:

[0054] (1) A set of prefabricated transparent molds: the transparent mold includes an inner film cover, a first outer mold cover and a second outer mold cover, the inner film cover is a cylindrical structure, and the inner film cover is provided with two first rings Draw-in slots, the first draw-in slots are respectively arranged at both ends of the inner membrane sleeve; the first outer die sleeve includes a first upper die sleeve and a first lower die sleeve with a semi-circular structure, the first upper die sleeve and the first The lower mold sleeves are closed to each other so that the first outer mold sleeve has a cylindrical structure as a whole. The first channel is formed in the first outer mold sleeve. The inner wall of the first channel is provided with a circle of first rubber bearing grooves with a rectangular cross-section. The ...

Embodiment 3

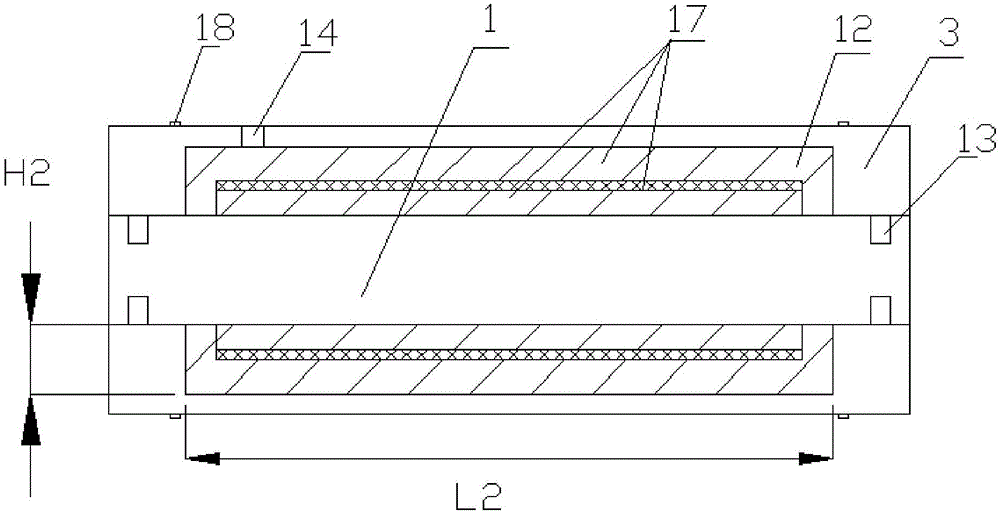

[0078] A heat-preserving and cold-preserving pipe outer protective prefabricated shell, the preparation method of which is as follows:

[0079] (1) A set of prefabricated transparent molds: the transparent mold includes an inner film cover, a first outer mold cover and a second outer mold cover, the inner film cover is a cylindrical structure, and the inner film cover is provided with two first rings Draw-in slots, the first draw-in slots are respectively arranged at both ends of the inner membrane sleeve; the first outer die sleeve includes a first upper die sleeve and a first lower die sleeve with a semi-circular structure, the first upper die sleeve and the first The lower mold sleeves are closed to each other so that the first outer mold sleeve has a cylindrical structure as a whole. The first channel is formed in the first outer mold sleeve. The inner wall of the first channel is provided with a circle of first rubber bearing grooves with a rectangular cross-section. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com