Method for producing composite copper powder for ultrathin heat pipe

A production method and technology of heat pipes, applied in the field of heat pipes, can solve the problems of difficulty in meeting the heat transfer requirements of ultra-thin heat pipes, slow water absorption rate, low porosity of liquid-absorbing cores, etc., and achieve irregular shape and bulk density. The effect of low and connected porosity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

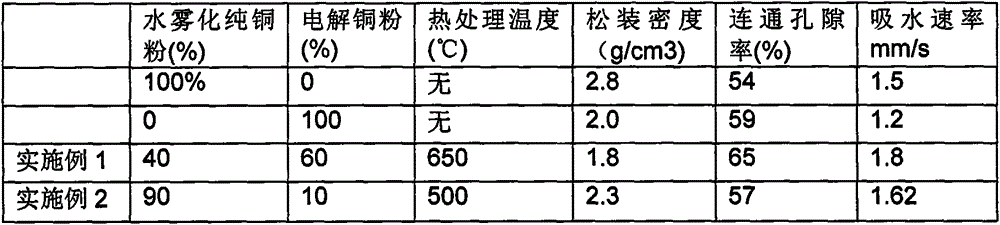

specific Embodiment 1

[0029] A production method of composite copper powder for ultra-thin heat pipes, said method comprising the steps of:

[0030] (1) Mixing powder: Mix the pure copper powder and electrolytic copper powder evenly with water atomized individual particles, wherein the electrolytic copper powder accounts for 60% of the weight of the mixing powder.

[0031] (2) Heat treatment: heat-treat the compounded powder obtained in the step (1) under a reducing atmosphere of hydrogen or nitrogen-hydrogen mixed gas, and the heat treatment temperature is 650°C.

[0032] (3) Crushing: using a hammer or jaw crusher to crush the powder obtained in the step (2) to obtain composite copper powder.

[0033] (4) Anti-oxidation treatment: Anti-oxidation treatment is carried out on the surface of the composite copper powder treated in the step (3) by using copper powder antioxidant.

[0034] (5) Sieving: sieve the composite copper powder after the treatment in the step (4), take the composite copper powd...

specific Embodiment 2

[0037] A production method of composite copper powder for ultra-thin heat pipes, said method comprising the steps of:

[0038] (1) Mixing powder: Mix the pure copper powder and the electrolytic copper powder evenly with water atomization, wherein the electrolytic copper powder accounts for 10% of the weight of the mixing powder.

[0039] (2) Heat treatment: heat-treat the compounded powder obtained in the step (1) under a reducing atmosphere of hydrogen or nitrogen-hydrogen mixed gas, and the heat treatment temperature is 500°C.

[0040] (3) Crushing: using a hammer or jaw crusher to crush the powder obtained in the step (2) to obtain composite copper powder.

[0041] (4) Anti-oxidation treatment: Anti-oxidation treatment is carried out on the surface of the composite copper powder treated in the step (3) by using copper powder antioxidant.

[0042] (5) Sieving: sieve the composite copper powder after the treatment in the step (4), take the composite copper powder with a part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com