Collagen matrix cartilage repairing membrane, and making method and application thereof

A collagen matrix, cartilage repair technology, applied in medical science, prosthesis and other directions, can solve problems such as cartilage calcification, and achieve the effects of inhibiting cartilage calcification, smooth surface and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

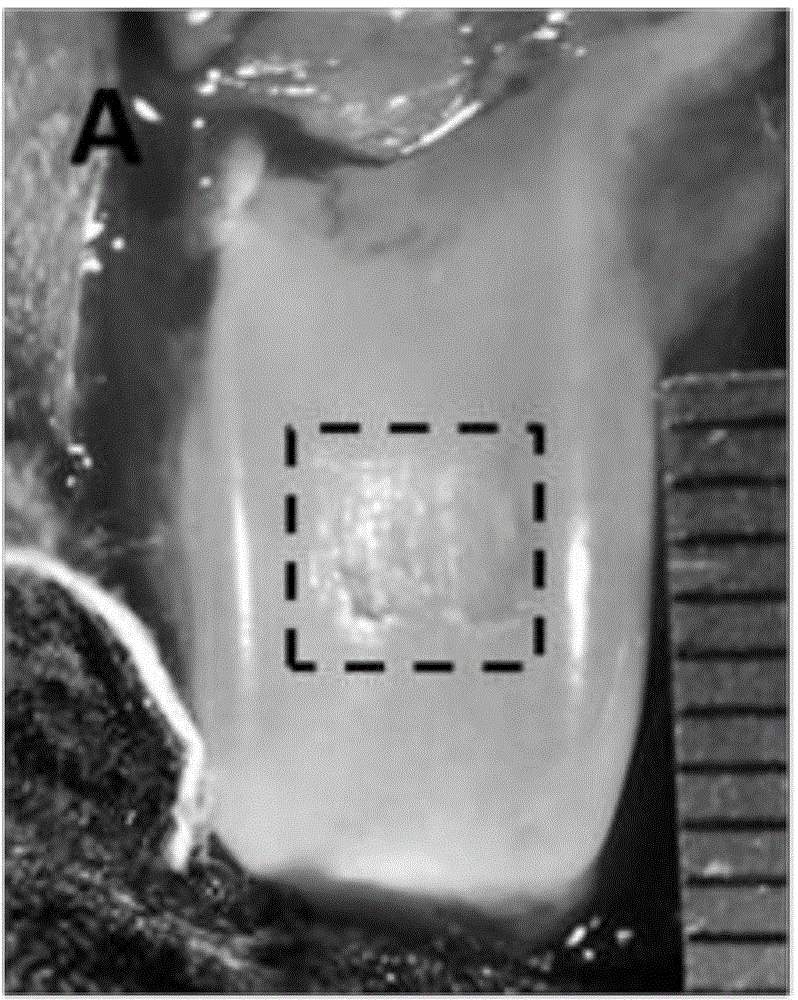

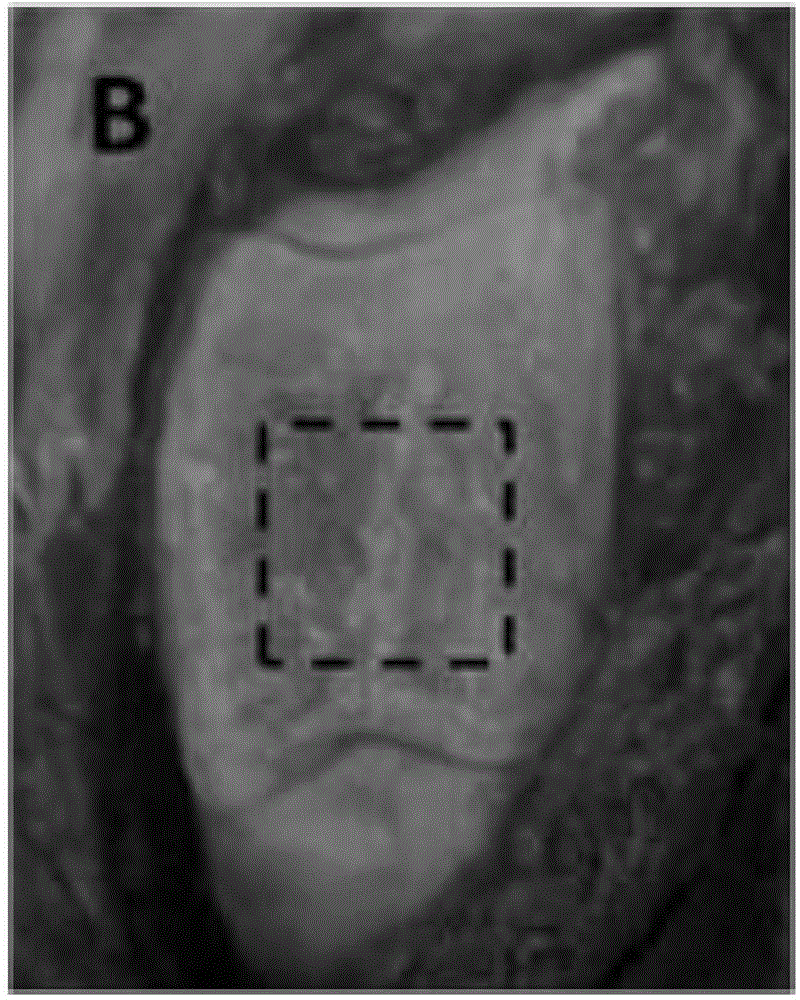

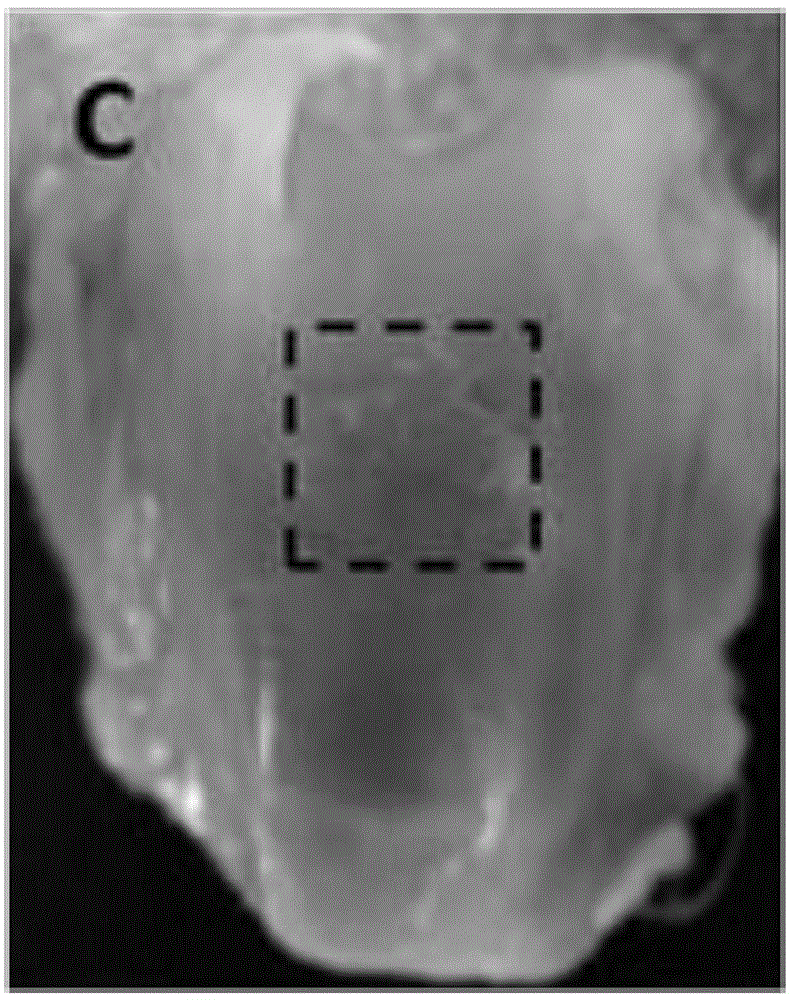

Image

Examples

Embodiment 1

[0028] A) Strip the tendon from the leg of a two-month-old healthy white pig, remove the fascia and fat, cut into pieces 120g, soak in 500mL of 75% ethanol aqueous solution at 4 ℃ overnight; B) take 95g of the tendon fragments from step A Rinse 5 times with distilled water, add 0.5mol / L acetic acid aqueous solution 1800mL, adjust pH to 1 with 6M sodium hydroxide aqueous solution, add pepsin (Sigma-ALDRICH) 9g, stand at 4 ℃ for 3 days, and obtain 1800mL collagen sol solution; C) Centrifuge the collagen sol solution obtained in step B horizontally at 4°C and 4000rpm for 25 minutes, discard the upper fat layer, dilute the precipitate a with 0.5mol / L acetic acid aqueous solution to 3 times the volume, and filter it with 4 layers of gauze in an ultra-clean bench. Mix the filtrate with 0.9mol / L NaCl aqueous solution at a volume ratio of 1:10, shake intermittently, overnight at 4°C, then centrifuge horizontally at 4°C and 4000rpm for 25 minutes, discard the supernatant and suspension ...

Embodiment 2

[0030]The water-soluble type I collagen extracted by the method in Example 1 was dissolved in deionized water to prepare 10 mL of a collagen aqueous solution with a concentration of 10 mg / mL, and 40 mL of a 1M sodium bicarbonate solution was added for neutralization. Take out 4.3mL of the neutralized type Ⅰ collagen solution and pour it into a 6cm diameter cell culture dish (Corning). Place the culture dish in an oven with a temperature of 37°C and dry it for 48 hours to form a type I collagen film in the mold. Take out the dried type Ⅰ collagen film and cut it into 5mm×5mm size. Take 10 slices of cut membranes, place them in a cell culture dish (Corning) with a diameter of 10 cm, and add 5 mL of parathyroid hormone-related peptide (Bachem) solution with a concentration of 100 ug / mL prepared in PBS (pH=7.4) , placed in a cell incubator and soaked at 37°C for 1 hour to obtain a type Ⅰ collagen membrane material compounded with parathyroid hormone-related peptide, that is, a co...

Embodiment 3

[0032] The water-soluble type I collagen extracted by the method in Example 1 was dissolved in deionized water to prepare 10 mL of a collagen aqueous solution with a concentration of 5 mg / mL, and 10 mL of a 1M sodium bicarbonate solution was added for neutralization. Take out 4.3mL of the neutralized type Ⅰ collagen solution and pour it into a 6cm diameter cell culture dish (Corning). Place the culture dish in an oven with a temperature of 37°C and dry it for 48 hours to form a type I collagen film in the mold. Take out the dried type Ⅰ collagen film and cut it into 5mm×5mm size. Take 10 slices of cut membranes, place them in a cell culture dish (Corning) with a diameter of 10 cm, and add 5 mL of parathyroid hormone-related peptide (Bachem) solution with a concentration of 100 ug / mL prepared in PBS (pH=7.4) , placed in a cell incubator at 37°C for 1 hour to obtain a type I collagen membrane material compounded with parathyroid hormone-related peptide, that is, a collagen matr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com