A Spandex Oil Agent with Universal Applicability

A technology of spandex oil agent and applicability, applied in the field of spandex oil agent, can solve the problems of narrow application range of spandex varieties, increased production cost of enterprises, and many types of spandex oil agent, so as to achieve enhanced effect, improved use effect, and improved smoothness. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A spandex oil agent with universal applicability, which is configured to put 60 g of mineral oil, 10 g of dimethyl silicone oil, and 20 g of block polyether silicone oil with a molecular weight of 500 to 800 and a carbon number of 12 to 20 into a reaction vessel. Stir and raise the temperature to 100°C, then add 2g sodium polyoxyethylene ether sulfonate, 1g fatty alcohol polyoxyethylene ether and 7g nano silicone oil: block polyether silicone oil, stir well for 1 hour until the liquid is transparent and uniform, and cool to normal temperature. The spandex oil is obtained.

Embodiment 2

[0018] A spandex oil agent with universal applicability, which is configured to put 50g of mineral oil, 10g of dimethyl silicone oil, 30g of block polyether silicone oil with molecular weight of 1000-2000 and carbon number of 12-20 into a reaction vessel, Stir and raise the temperature to 100°C, then add 1g isotridecyl ether phosphate, 3g fatty alcohol polyoxyethylene ether and 6g nano silicone oil: block polyether silicone oil, stir well for 1 hour until the liquid is transparent and uniform, and cool to normal temperature. The spandex oil is obtained.

Embodiment 3

[0020] A spandex oil agent with universal applicability. It is configured to put 65g of mineral oil, 15g of dimethyl silicone oil, 10g of block polyether silicone oil with a molecular weight of about 3000 and carbon atoms of 12-20 into the reaction vessel, and stir And the temperature is raised to 100°C, and then 1g linear sodium dodecylbenzene sulfonate, 1g oleyl alcohol polyoxyethylene ether and 8g nano silicone oil: block polyether silicone oil are added in sequence, and the liquid is fully stirred for 1 hour until the liquid is transparent and uniform, and the temperature is reduced to At room temperature, spandex oil is obtained.

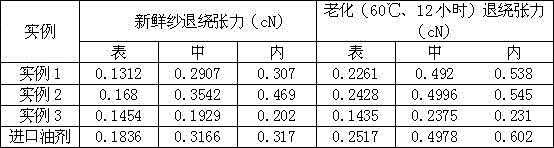

[0021] The oil agent prepared by the above method is used for dry spinning to prepare spandex yarn, the oiling rate is 5%, the oil is applied by the drum method, and the cheese is wound at 600m / min to obtain 40D spandex yarn. The unwinding tension of the surface, middle and inner layers of the fresh yarn and the aged yarn aged at 60°C for 12 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com