Organosilicon drying insulating varnish and preparation method thereof

A technology of insulating varnish and silicone, applied in the direction of coating, etc., can solve problems such as poor water resistance, poor water resistance, and heat resistance that cannot meet the requirements, and achieve convenient construction, wide application range, and high breakdown strength index Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of organosilicon drying insulation varnish, comprises following components, by weight (g),

[0022]

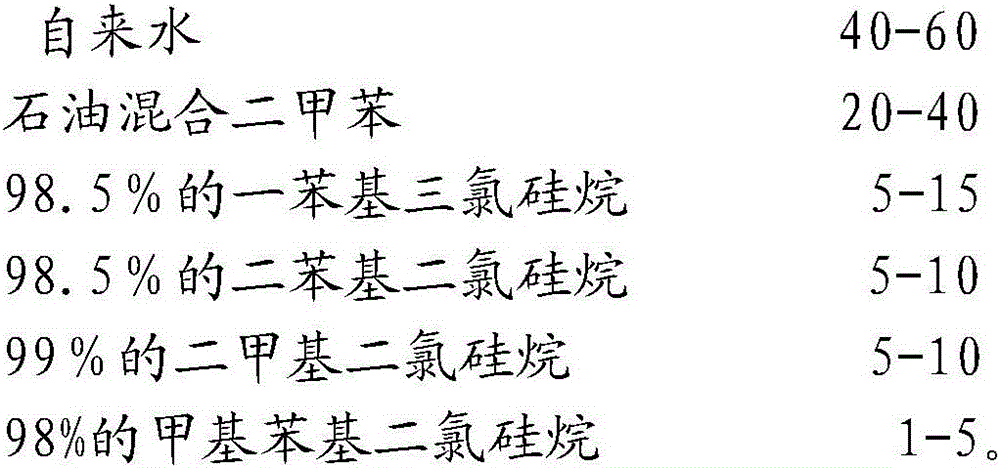

[0023] The self-made concentrated silanol is made up of the following components, by weight (g),

[0024]

[0025] The self-made concentrated silanol preparation method of embodiment 1, carry out as follows,

[0026] ①Mix 15g of 98.5% monophenyltrichlorosilane, 5g of 98.5% diphenyldichlorosilane, 5g of 99% dimethyldichlorosilane and 5g of 98% methylphenyldichlorosilane with petroleum Add 15g of toluene to the dropping tank, stir for 10 minutes, and mix well to make a mixed monomer for later use;

[0027] ②Put 40g of tap water and 5g of the remaining petroleum-mixed xylene into the hydrolysis kettle, start stirring, pass cold water through the jacket, control the hydrolysis temperature at 35-50°C, and start to drop the mixed monomer in step ① at the same time. After the dropwise addition, continue to stir for 10 minutes, stop stirring and stop the jacket t...

Embodiment 2

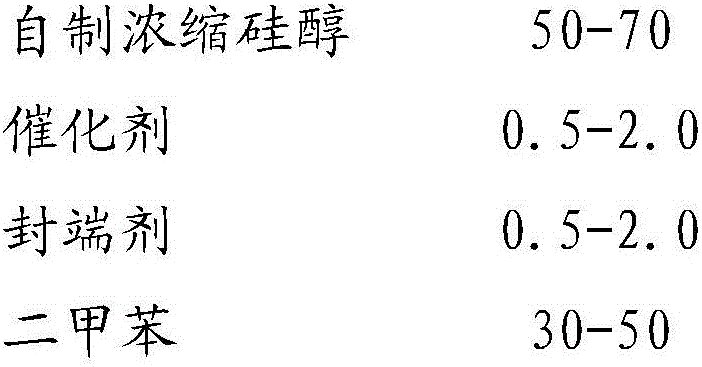

[0031] A kind of organosilicon drying insulation varnish, comprises following components, by weight (g),

[0032]

[0033] The self-made concentrated silanol is made up of the following components, by weight (g),

[0034]

[0035] Carry out according to the self-made concentrated silanol preparation method of embodiment 1.

Embodiment 3

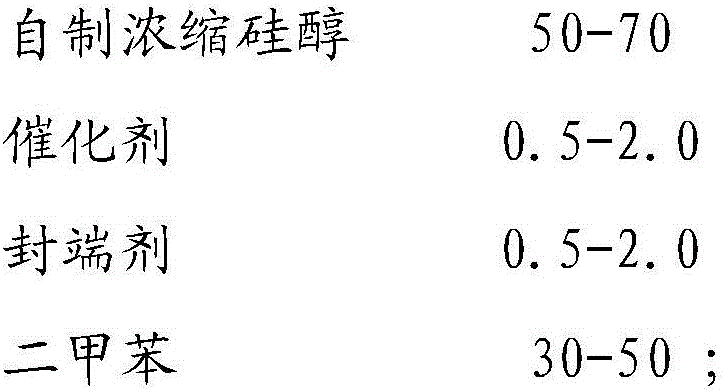

[0037] A kind of organosilicon drying insulation varnish, comprises following components, by weight (g),

[0038]

[0039] The self-made concentrated silanol is made up of the following components, by weight (g),

[0040]

[0041] Carry out according to the self-made concentrated silanol preparation method of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com