Ink composition and preparation method thereof

An ink composition and uniform mixing technology, applied in inks, household appliances, applications, etc., can solve the problems of difficult to control the viscosity of conductive ink, short storage time, long drying and curing time of conductive ink, etc., to achieve excellent electrical connection performance, The effect of moderate viscosity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Weighing 15kg of aluminum powder with a particle size of 20 microns, 3.5kg of Tween 40, 3kg of diglycidyl phthalate, 2.5kg of polyepoxysuccinic acid, 3kg of white carbon black, and azobisisobutyronitrile 2kg and urea 3kg;

[0024] (2) Add the above components into a three-roll mill and grind at 110°C for 10 minutes, and keep warm at 155°C for 3 hours;

[0025] (3) Add 30 kg of diethylene glycol diethyl ether to the product in step 2, and ultrasonicate for 15 minutes under airtight conditions at a temperature of 60° C. to obtain an ink composition.

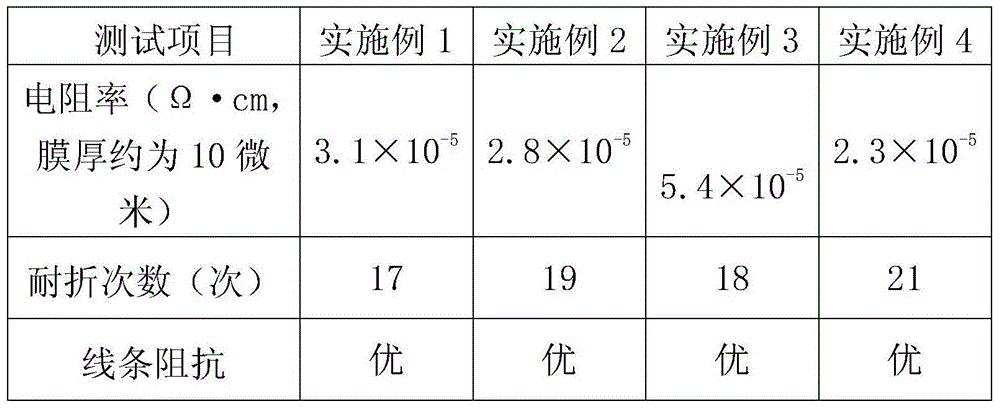

[0026] The performance test results of the prepared ink composition are shown in Table 1.

Embodiment 2

[0028] (1) Take by weighing particle diameter and be the copper powder 20kg of 30 microns, 5kg Tween 20, diglycidyl phthalate 5kg, polyepoxysuccinic acid 3kg, white carbon black 2kg, azobisisobutyronitrile 3kg and Urea 2kg;

[0029] (2) Add the above components into a three-roll mill and grind at 125°C for 15 minutes, and keep warm at 160°C for 2 hours;

[0030] (3) Add 26 kg of diethylene glycol diethyl ether to the product in step 2, and ultrasonicate for 20 minutes under airtight conditions at a temperature of 50° C. to obtain an ink composition.

[0031] The performance test results of the prepared ink composition are shown in Table 1.

Embodiment 3

[0033] (1) Take by weighing 25kg of zinc powder, 4kg of Tween 60, 4kg of diglycidyl phthalate, 2.5kg of polyepoxysuccinic acid, 4kg of white carbon black, and 2kg of azobisisobutyronitrile with a particle size of 25 microns and urea 2.5kg;

[0034] (2) Add the above components into a three-roll mill and grind at 115°C for 20 minutes, and keep warm at 160°C for 3 hours;

[0035] (3) Add 20 kg of diethylene glycol diethyl ether to the product in step 2, and ultrasonicate for 15 minutes under airtight conditions at a temperature of 55° C. to obtain an ink composition.

[0036] The performance test results of the prepared ink composition are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com