Method for preparing concrete from abandoned glass and glass particle screening machine used in same

A technology for waste glass and glass particles, which is applied to chemical instruments and methods, filtration, solid separation, etc. It can solve the problems of harsh screening environment and achieve high practical value, high screening stability, and smooth and stable collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

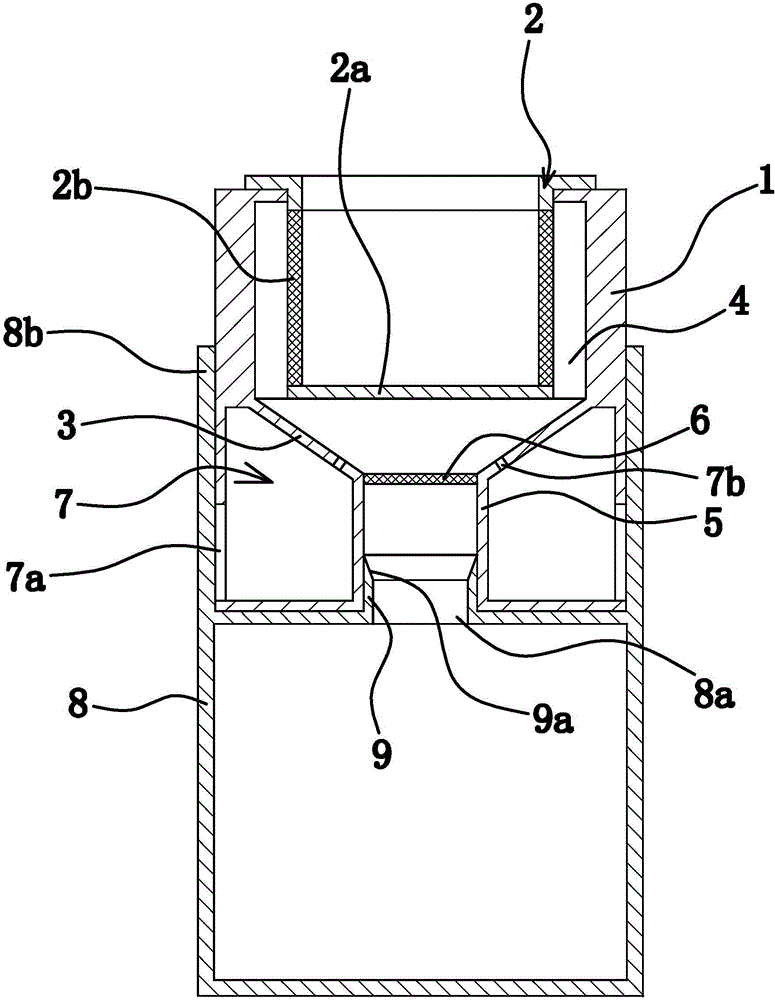

Image

Examples

Embodiment 1

[0044] The method for preparing concrete from waste glass comprises the following steps:

[0045] A. Weighing: Weigh cement, waste glass micropowder, silica fume, waste glass fine aggregate, natural coarse aggregate and water according to the mixing ratio. The mass ratio of the above components is 1:0.2:0.02:2:2.5: 0.4.

[0046] The particle size of waste glass powder is less than or equal to 0.16 mm.

[0047] The particle size of waste glass fine aggregate is less than or equal to 5mm.

[0048] The apparent density of silica fume is 24.5m 2 / g.

[0049] B. One-time stirring: mix and stir the above-mentioned silica fume, natural coarse aggregate and 50% cement with the above-mentioned 30% water, and the stirring time is 15 seconds. After fully stirring, a semi-finished concrete product is obtained;

[0050] C. Secondary stirring: put all the remaining components weighed in step A into the semi-finished concrete and stir again, the stirring time is 120 seconds, and the finish...

Embodiment 2

[0061] The method for preparing concrete from waste glass comprises the following steps:

[0062] A. Weighing: Weigh cement, waste glass micropowder, silica fume, waste glass fine aggregate, natural coarse aggregate and water according to the mixing ratio. The mass ratio of the above components is 1:0.35:0.07:2—2.5: 3:0.6.

[0063] The particle size of waste glass powder is less than or equal to 0.16 mm.

[0064] The particle size of waste glass fine aggregate is less than or equal to 5mm.

[0065] The apparent density of silica fume is 24.5m 2 / g.

[0066] B. One-time stirring: mix and stir the above-mentioned silica fume, natural coarse aggregate and 50% cement with the above-mentioned 30% water. The stirring time is 60 seconds, and the concrete semi-finished product is obtained after fully stirring;

[0067] C. Secondary stirring: put all the remaining components weighed in step A into the semi-finished concrete and stir again, the stirring time is 180 seconds, and the ...

Embodiment 3

[0069] The method for preparing concrete from waste glass comprises the following steps:

[0070] A. Weighing: Weigh cement, waste glass micropowder, silica fume, waste glass fine aggregate, natural coarse aggregate and water according to the mixing ratio. The mass ratio of the above components is 1:0.3:0.05:2.2:2.8: 0.5.

[0071] The particle size of waste glass powder is less than or equal to 0.16 mm.

[0072] The particle size of waste glass fine aggregate is less than or equal to 5mm.

[0073] The apparent density of silica fume is 24.5m 2 / g.

[0074] B. One-time stirring: mix and stir the above-mentioned silica fume, natural coarse aggregate and 50% cement with the above-mentioned 30% water. The stirring time is 40 seconds, and the concrete semi-finished product is obtained after fully stirring;

[0075] C. Secondary stirring: put all the remaining components weighed in step A into the semi-finished concrete and stir again. The stirring time is 150 seconds, and the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com