Steel wire or bar

A steel wire rod and quality technology, applied in the field of steel wire rod or bar steel, can solve the problem that the oxidation depth of the grain boundary is not specified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0136] The present invention is specifically described below by way of examples. Wherein, these examples are used to illustrate the present invention, but not to limit the scope of the present invention.

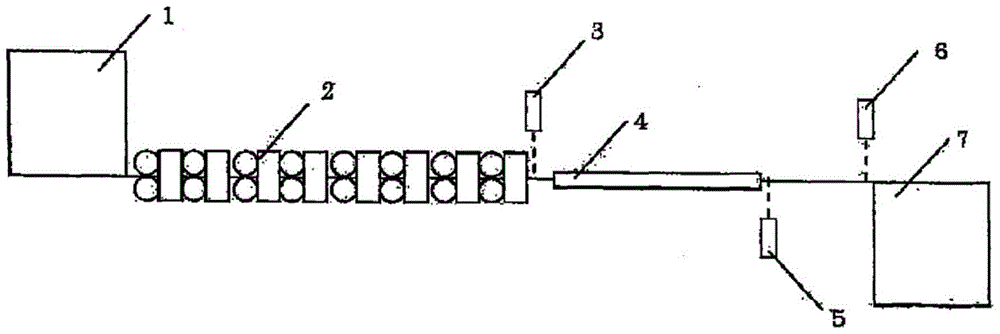

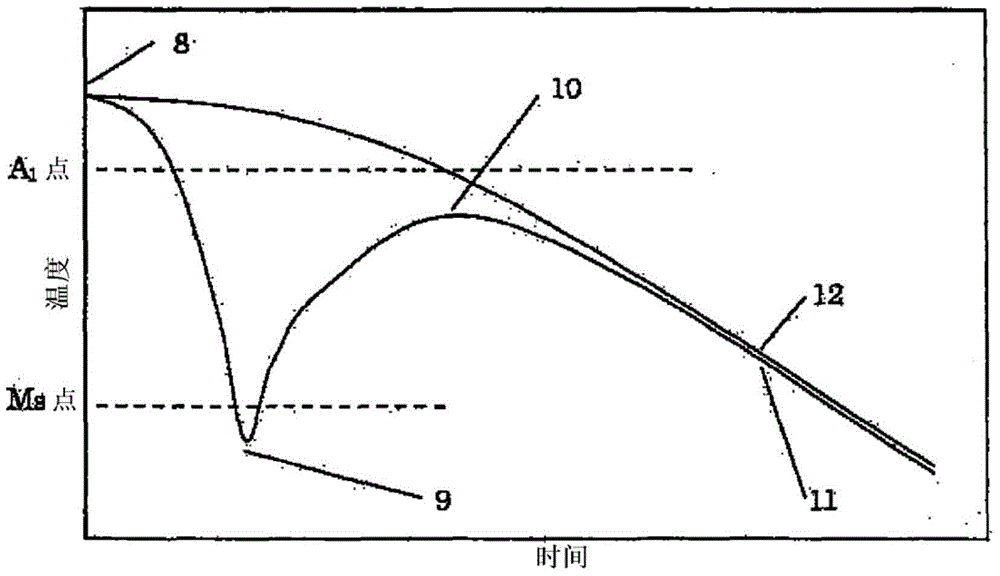

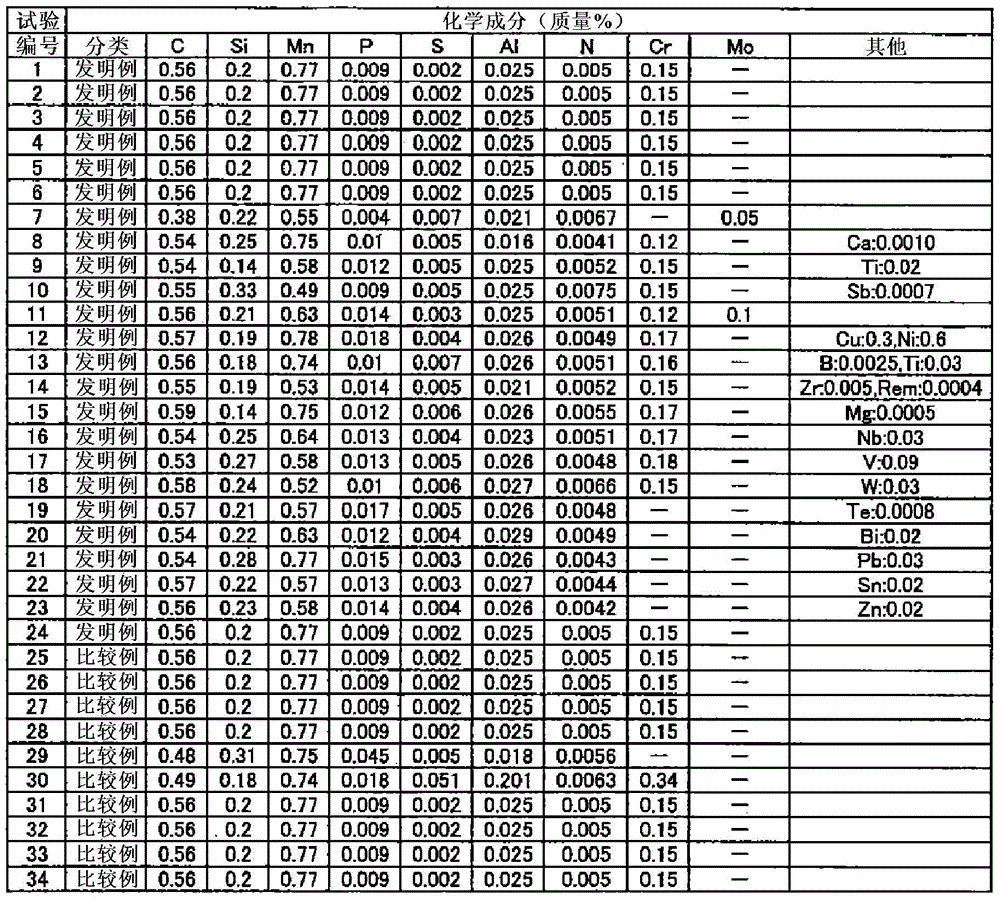

[0137] A 162 mm square billet having the chemical composition shown in Table 1 was rolled into a φ45 mm steel bar according to the conditions in Table 2, and immediately after rolling, it was rapidly cooled, reheated, and then air-cooled. The final rolling temperature, cooling temperature, and reheating temperature were measured with a radiation thermometer. figure 1 The positional relationship of each radiation thermometer, rolling mill, water cooling device, and cooling bed is illustrated, figure 2 Temperature changes are illustrated. That is, as an example of the summary of the rolling line related to the present invention figure 1 As shown, a steel slab heated in a heating furnace 1 is rolled in a hot rolling mill 2 , and the final temperature is measured with a fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com