Heat pump, in particular for heating a vehicle interior, and method for operating a heat pump

A vehicle interior and heat pump technology, which is applied to the operation mode of machines, vehicle components, heat pumps, etc., can solve problems such as high driving energy, and achieve the effects of low driving energy consumption and environmental protection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

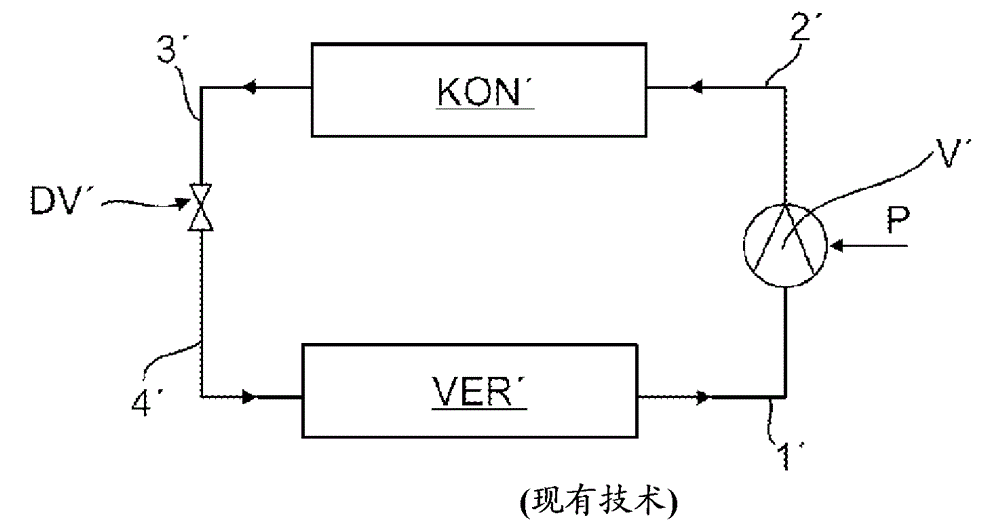

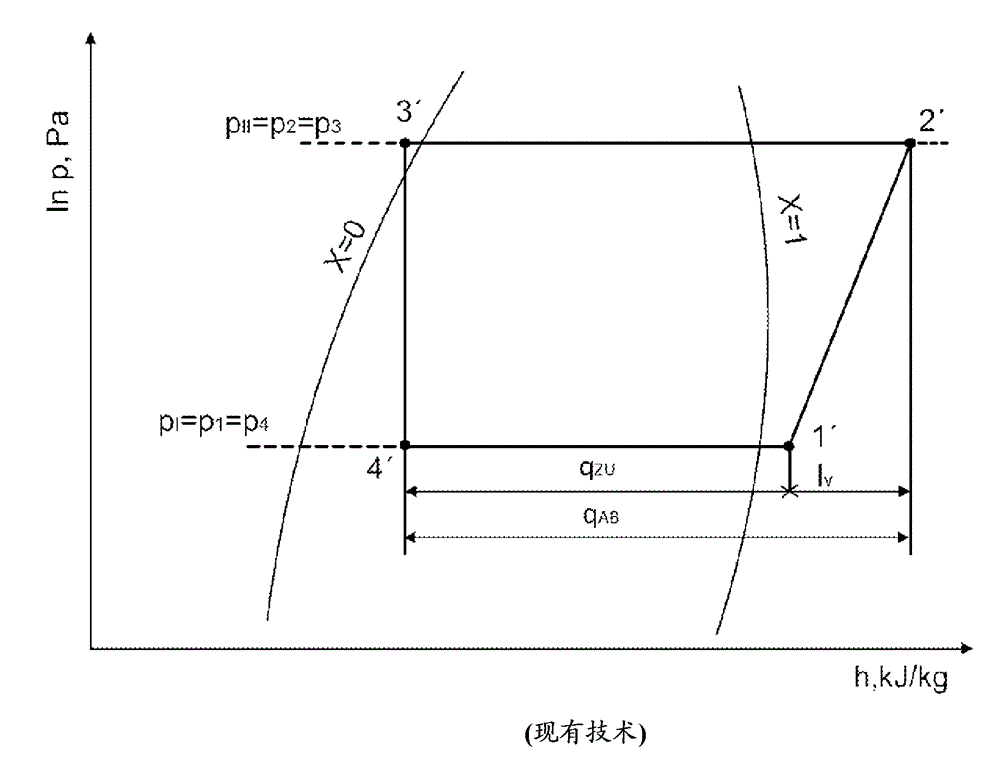

[0047] Figure 4 Diagram showing a left-handed compression / cold vapor cycle process (KKKP) of a heat pump without a jet pump according to the prior art (the reference numbers used are intended to depict both the connecting line and the working medium contained in each case in the connecting line or, and their current state):

[0048] The working medium (coolant) is compressed in a known manner as a superheated fluid in the compressor V' (multiple compression 1'→2') and fed to the condenser KON'. The latent and sensible heat of the fluid (2'→3') is transferred in the condenser KON directly to the vehicle interior, such as the passenger space or the driver's cabin, or indirectly as usable heat to the auxiliary medium circuit of the vehicle. After the phase change in the condenser KON', the working medium is throttled in the subsequent throttle valve DV' (via the Joule-Kelvin effect, 3'→4'). At the end of the throttling process, the working medium achieves the wet steam paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com