Grain pulp using high-temperature alpha-amylase and preparation method thereof

An amylase and product technology, applied in the field of cereal pulp products and their preparation, can solve the problems of poor operability of the technological process, difficult enzymatic hydrolysis temperature control, treatment of by-products of enzymatic hydrolysis products and poor product quality, etc. The effect of using efficiency and saving batching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

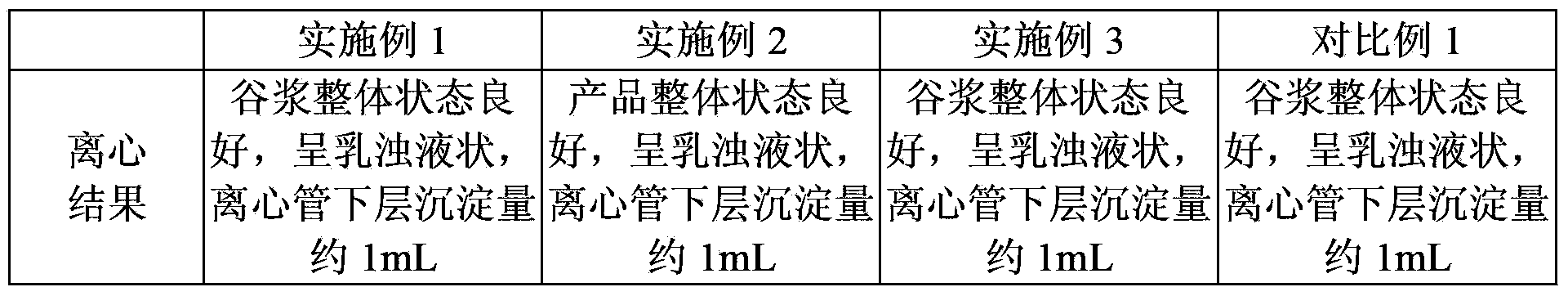

Examples

Embodiment 1

[0036] This example provides an enzymatic hydrolysis mung bean product, which is a cereal pulp product with the following raw material composition (based on one ton product):

[0037] Enzymatic mung bean milk (mass ratio of mung bean powder to water is 35:65) 998.7 kg

[0038] Gellan gum 1.3 kg.

[0039] This product is produced through the following steps:

[0040] 1. Ingredients: Heat the ingredient water accounting for 50% of the ingredient amount (this ingredient amount refers to the ingredient amount in the process of enzymatically hydrolyzing the grain alone, that is, the water used to prepare the enzymatic mung bean milk) to 85°C, add the grain powder, and stir to make the grain The powder is evenly dissolved and dispersed to obtain a grain slurry.

[0041] 2. Keep the temperature of the grain slurry at 80°C, control the stirring speed at 100 rpm, add the high-temperature α-amylase to 0.9% of the total weight of the grain flour, keep it at a constant temperature, and ...

Embodiment 2

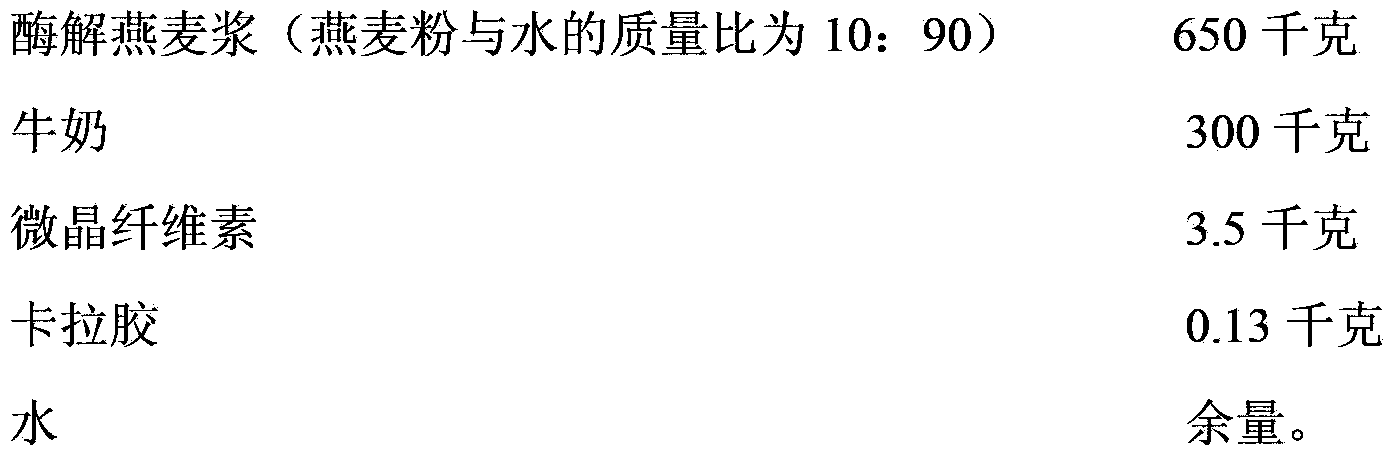

[0049] This embodiment provides an enzymatic hydrolysis oat milk product, which is a cereal pulp product, and has the following raw material composition (based on one ton of product):

[0050]

[0051] This product is produced through the following steps:

[0052] 1. Ingredients: Heat the ingredient water accounting for 50% of the ingredient amount (this ingredient amount refers to the ingredient amount in the process of enzymatically hydrolyzing the grain alone, that is, the water used to prepare the enzymatic oat pulp) to 83°C, add oat flour, and stir to make the oatmeal The powder is evenly dissolved and dispersed to obtain a thick oatmeal slurry.

[0053]2. Keep the temperature of the thick oat slurry at 83°C, control the stirring speed at 800 rpm, add high-temperature α-amylase, the amount of high-temperature α-amylase accounts for 1.5% of the total weight of the grain flour, and maintain a constant temperature. The viscosity of the product was detected every 10 minut...

Embodiment 3

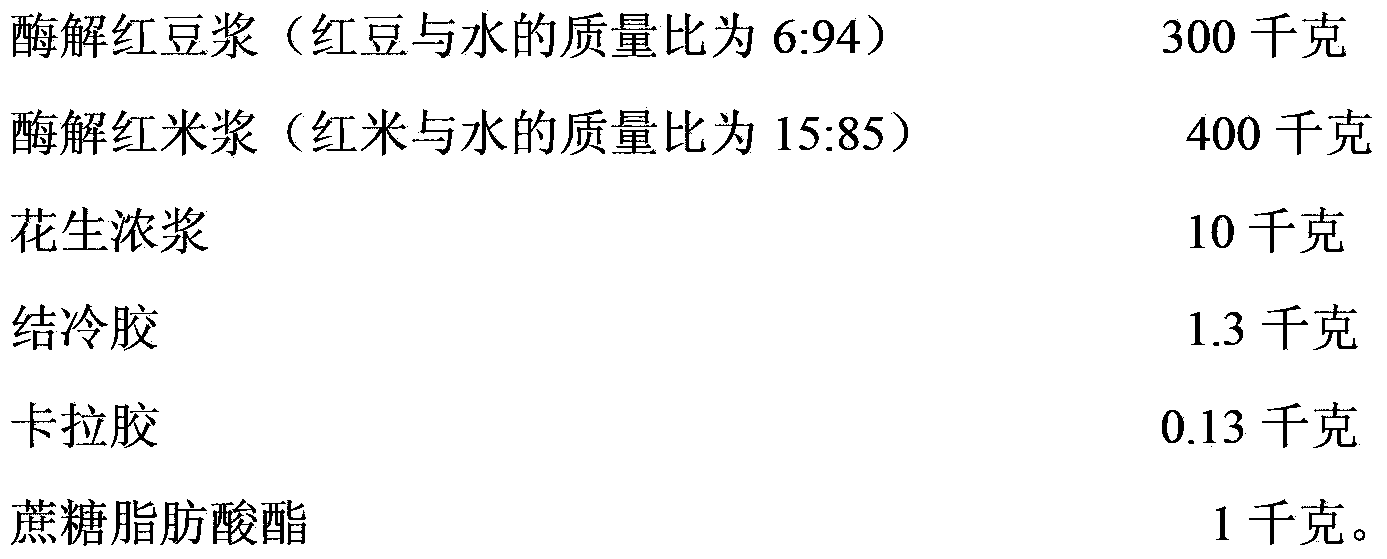

[0061] This embodiment provides an enzymolysis red grain product, which is a kind of cereal pulp product, and has the following raw material composition (calculated by one ton of product):

[0062]

[0063] This product is produced through the following steps:

[0064] 1. Ingredients: Heat 50% of the ingredient water (this ingredient refers to the ingredient amount in the process of enzymatically hydrolyzing the grain alone, that is, the water used to prepare the enzymatic red bean milk) to 80°C, add red bean powder, and stir to make the red bean The powder is evenly dissolved and dispersed to obtain red bean thick paste; the batching water accounting for 50% of the batching amount (this batching amount refers to the batching amount in the process of enzymatically hydrolyzing the grain alone, that is, the water used to prepare the enzymatically hydrolyzed red rice slurry) is heated to 82°C Add red rice flour and stir to dissolve and disperse the red rice flour evenly to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com