Preparation method of porous metal nickel and nickel-based porous film super-capacitor electrode material on surface of porous metal nickel

A technology of supercapacitor electrodes and porous metals, which can be used in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, and can solve problems such as insufficient cost and process difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The embodiment of the present invention provides a method for preparing porous metal nickel and its surface nickel-based oxide porous thin film supercapacitor electrode material, comprising the following steps:

[0025] S10, cleaning the metal nickel base;

[0026] S20, the metal nickel base is used as the positive electrode and the platinum sheet is used as the negative electrode, and the metal nickel base of the positive electrode is anodized by a step anodic oxidation method to form porous nickel;

[0027] S30, treating the porous nickel obtained in step S20 in a 1M-6M alkali solution by cyclic voltammetry at a rate of 10mV / s-100mV / s to obtain a porous nickel oxide film;

[0028] Alternatively, the porous nickel obtained in step S20 is treated with a constant current charge and discharge method with a surface current density of 1mA / cm2-60mA / cm2 in a lye solution of 1M to 6M to obtain porous metal nickel and its surface nickel-based oxide A method for preparing a por...

Embodiment 1

[0039] S10, put 1cm 2 Metal nickel is cleaned by ultrasonic cleaning with acetone, ethanol and deionized water for 10 minutes each;

[0040] S20, in a common power supply, use a nickel sheet as the positive electrode, a platinum sheet as the negative electrode, and use a cesium fluoride solution containing 1M sulfuric acid and 0.02M as the electrolyte, and carry out step anodic oxidation treatment under stirring conditions; wherein,

[0041] The step length is 5s, and the step length of each step is equal, and each step is boosted by 0.1V, so that the voltage rises to 1.2V, and then the constant potential is maintained for 4h to form porous nickel oxide;

[0042] S30, treating the porous nickel oxide in 1M potassium hydroxide or sodium hydroxide aqueous solution with a voltage change rate of 10 mV / s by cyclic voltammetry, and obtaining a porous nickel oxide film after 48 hours of treatment.

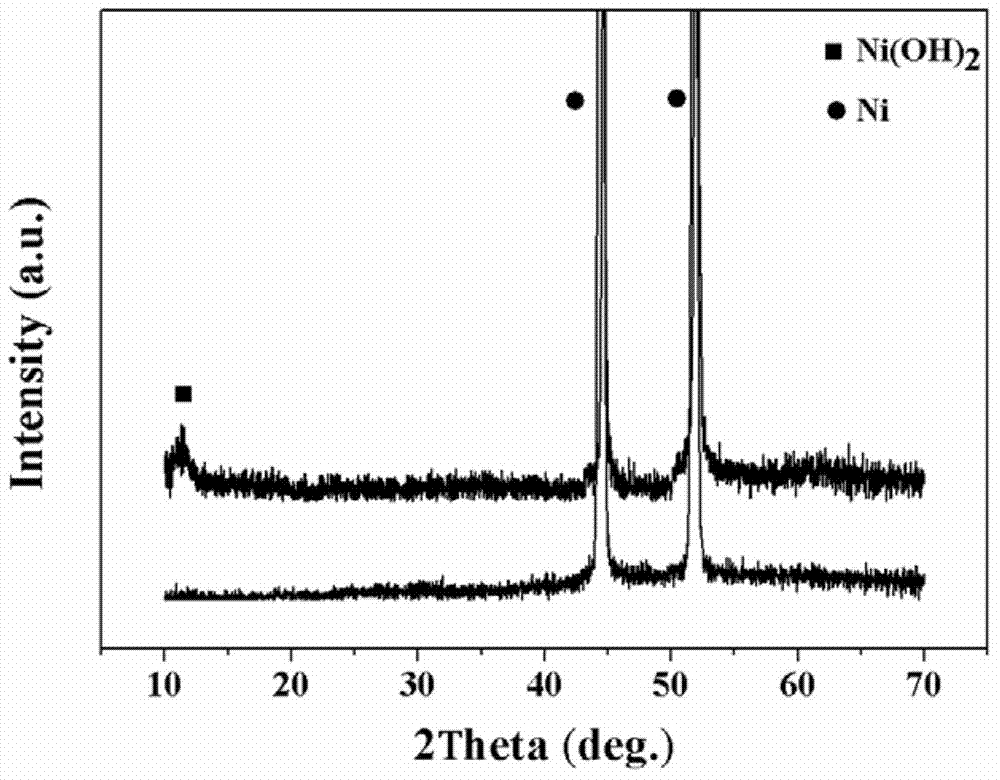

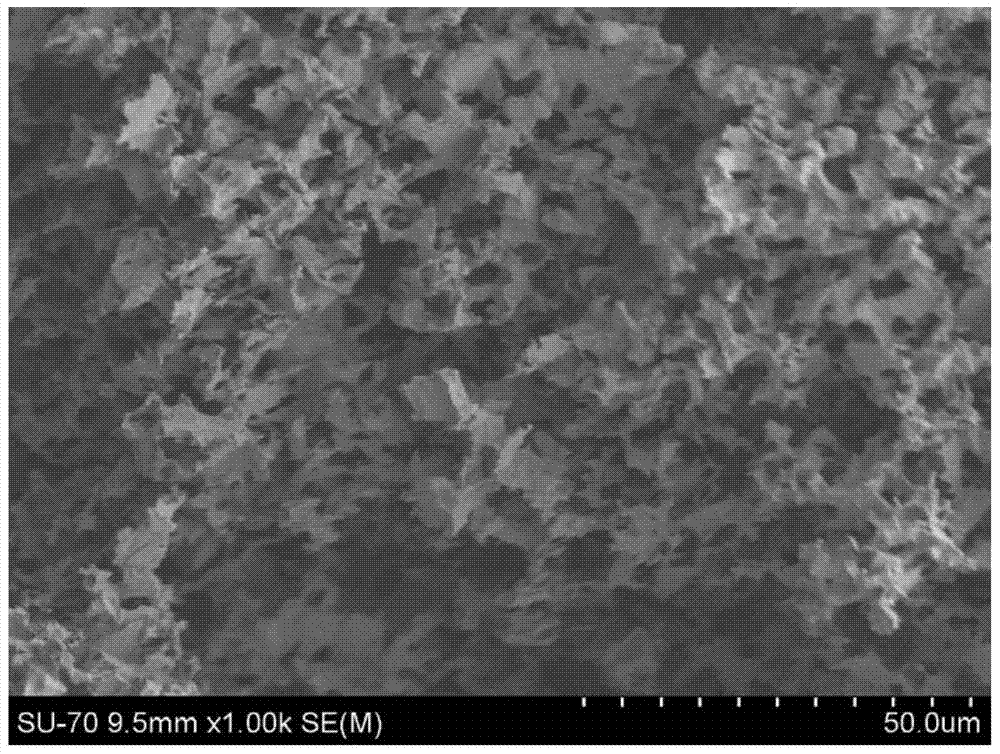

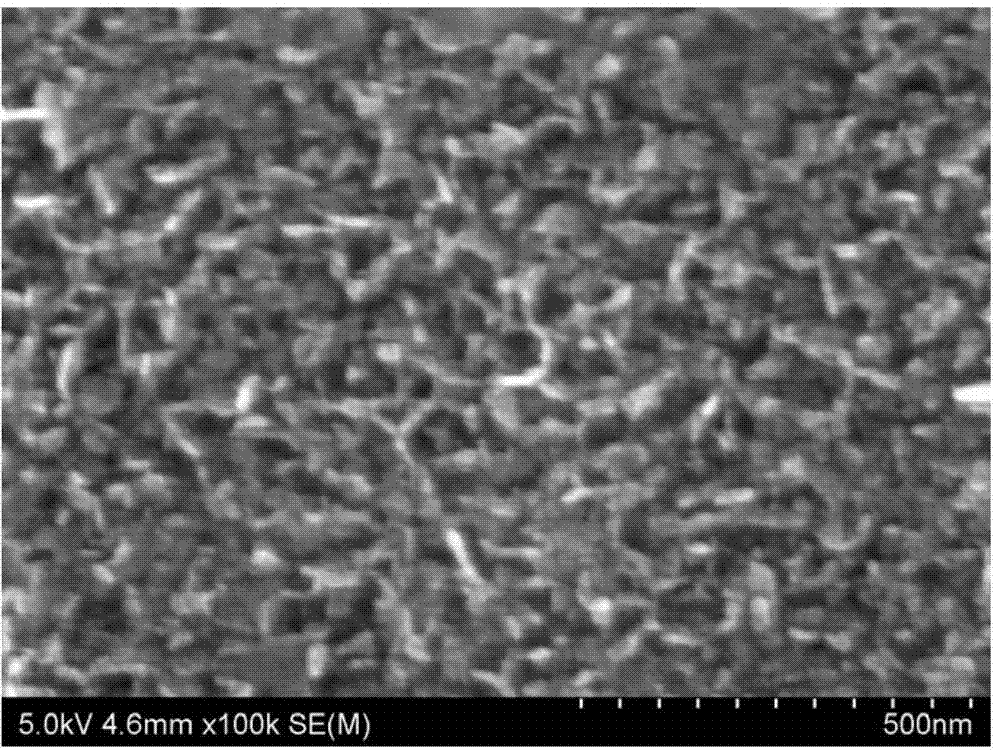

[0043] The porous nickel oxide film obtained in the present embodiment 1 was tested ...

Embodiment 2

[0045] S10, put 1cm 2 Metal nickel is cleaned by ultrasonic cleaning with acetone, ethanol and deionized water for 10 minutes each;

[0046] S20, under a programmable DC power supply, with a nickel sheet as the positive electrode, a platinum sheet as the negative electrode, and a solution containing 1M sulfuric acid and 0.02M cesium fluoride as the electrolyte; step anodic oxidation treatment is performed under stirring conditions, wherein,

[0047] The step length is 10s, and each step is equal in length, and the voltage is boosted by 0.1V in each step, so that the voltage rises to 1.2V, and then the constant potential is maintained for 3h to form porous nickel oxide;

[0048] S30, treating the porous nickel oxide with cyclic voltammetry at a rate of 20 mV / s in 1M potassium hydroxide or sodium hydroxide aqueous solution for 120 hours to obtain a porous nickel oxide film.

[0049] The porous nickel oxide film obtained in this embodiment 2 was tested at 40mA / cm 2 Under the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com