Electrical-vehicle charging pile cable capable of transmitting temperature measurement and control signals

A technology for electric vehicles and charging piles, which can be used in power cables, power cables with shielding/conductive layers, insulated cables, etc., and can solve problems such as fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

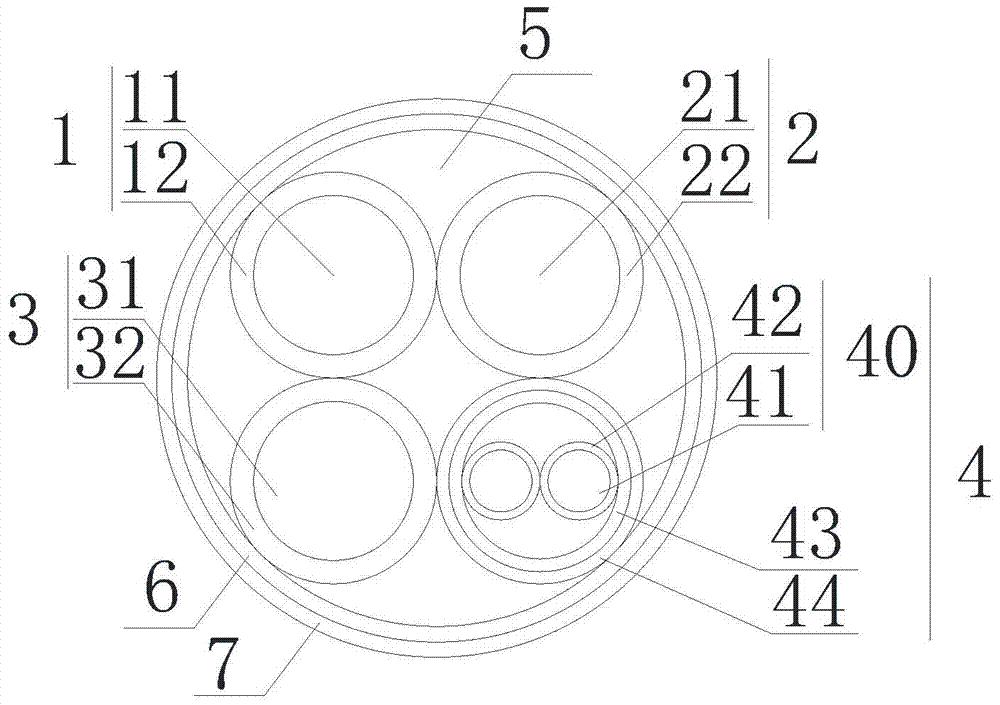

Embodiment 1

[0027] The first insulating layer 12, the second insulating layer 22, the third insulating layer 32, the fourth insulating layer 42 and the outer sheath 7 in the present invention are all made of low-smoke, halogen-free, oil-resistant radiation-resistant cross-linked TPE materials. Include by weight: 48 parts of styrene-butadiene block copolymer SBS, 42 parts of hydrogenated nitrile rubber, 16 parts of epoxy resin, 11 parts of jute fiber, 1.1 parts of titanate coupling agent TMC-114, weight 28 parts of calcium carbonate, 20 parts of white carbon black, 15 parts of sepiolite powder, 3 parts of titanium nitride, 4 parts of trimellitic acid tris(n-octyl-n-decyl ester) NODTM, 5 parts of epoxy tall oleate butyl ester, hydrogen 4 parts of alumina, 1.5 parts of melamine cyanurate, 3 parts of microencapsulated red phosphorus, and 1.1 parts of anti-aging agent OD.

Embodiment 2

[0029]The first insulating layer 12, the second insulating layer 22, the third insulating layer 32, the fourth insulating layer 42 and the outer sheath 7 in the present invention are all made of low-smoke, halogen-free, oil-resistant radiation-resistant cross-linked TPE materials. Including by weight: 50 parts of styrene-butadiene block copolymer SBS, 40.5 parts of hydrogenated nitrile rubber, 18 parts of epoxy resin, 9.8 parts of jute fiber, 1.2 parts of titanate coupling agent TMC-114, weight 25 parts of high-quality calcium carbonate, 21.4 parts of white carbon black, 13.7 parts of sepiolite powder, 3.4 parts of titanium nitride, 3.7 parts of trimellitic acid tris(n-octyl-n-decyl ester) NODTM, 6.2 parts of epoxy tall oleate butyl ester, hydrogen 3.3 parts of alumina, 2.2 parts of melamine cyanurate, 2.4 parts of microencapsulated red phosphorus, and 1.5 parts of anti-aging agent OD.

Embodiment 3

[0031] The first insulating layer 12, the second insulating layer 22, the third insulating layer 32, the fourth insulating layer 42 and the outer sheath 7 in the present invention are all made of low-smoke, halogen-free, oil-resistant radiation-resistant cross-linked TPE materials. Include by weight: 49 parts of styrene-butadiene block copolymer SBS, 41 parts of hydrogenated nitrile rubber, 17 parts of epoxy resin, 10 parts of jute fiber, 1.2 parts of titanate coupling agent TMC-114, weight 26 parts of high-quality calcium carbonate, 21 parts of white carbon black, 14 parts of sepiolite powder, 3.3 parts of titanium nitride, 3.8 parts of trimellitic acid tris (n-octyl-n-decyl ester) NODTM, 6 parts of epoxy tall oleate butyl ester, hydrogen 3.4 parts of alumina, 1.8 parts of melamine cyanurate, 2.6 parts of microencapsulated red phosphorus, and 1.4 parts of anti-aging agent OD.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com