Assembly method of microstructure pressing triple prism made from PMMA polymer material

A polymer material and assembly method technology, applied in the field of medical devices, can solve the problem that the prism cannot adopt the film-mounted assembly method, etc., and achieve the effect of preventing the entry of pollutants and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

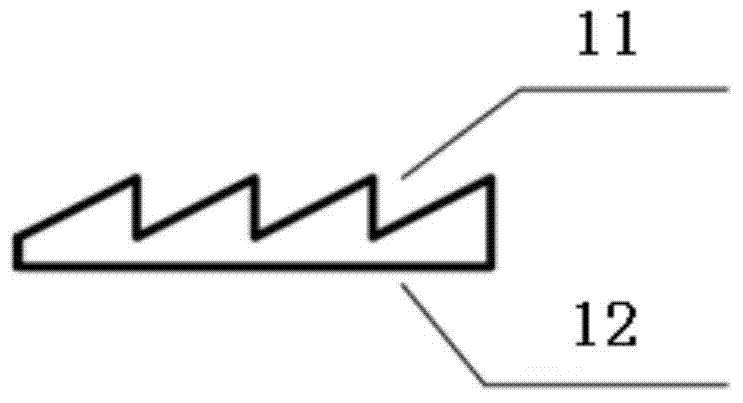

[0025] The technical scheme that the present invention solves its technical problem adopts is: the microstructure press-fit prism assembly method that is used for PMMA polymer material, comprises the following steps:

[0026] (1) On the bottom surface of the PMMA pressing prism, the glass plate is welded by ultrasonic welding technology, so that the bottom surface of the PMMA pressing prism is fixed on the glass plate;

[0027] (2) Use a diamond cutting machine to cut out the glass plate that has fixed the PMMA pressed prism, and the free boundary needs to exceed the outline of the PMMA pressed prism;

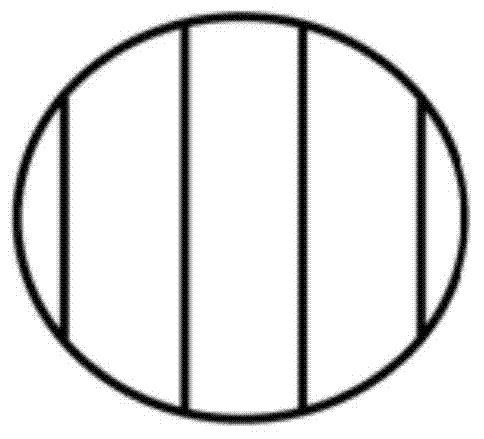

[0028] (3) Etch the same assembly line as the outline of the glass plate on the inner layer of the lens of the ordinary spherical mirror that needs to be installed;

[0029] (4) The PMMA pressed triangular prism microstructure layer is aligned with the inner layer of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com