Corrosion-resistant composite section bar and preparation method thereof

A composite profile, corrosion-resistant technology, applied in the direction of building components, etc., can solve problems such as unsatisfactory corrosion resistance, achieve the effect of improving service quality and operating life, reducing infrastructure and engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

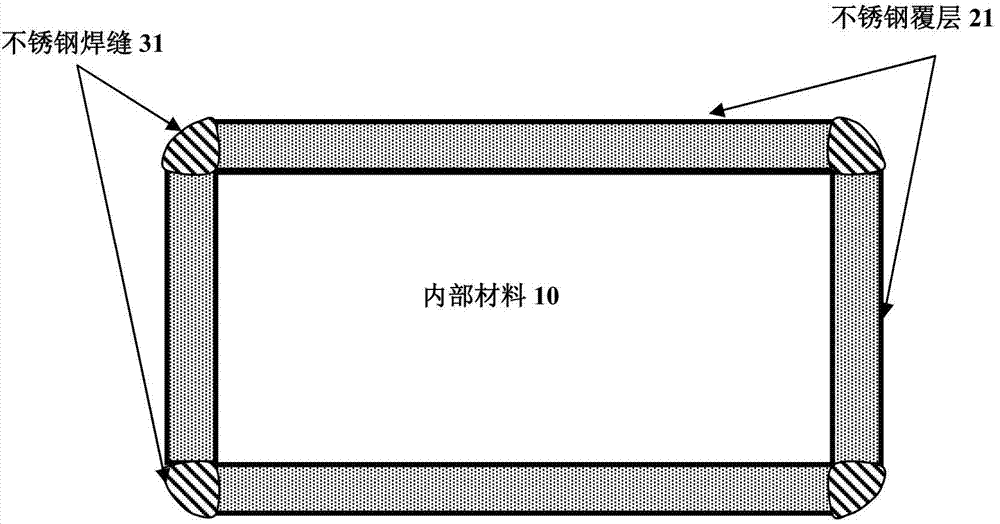

[0057] Q235B continuous casting billet (160mm×160mm) and 304 stainless steel plate (thickness 12mm) were selected as internal material and external cladding respectively. Cut the 304 stainless steel plate into a width of 640mm, bend it and carry out degreasing pickling and activation treatment. Then, follow Figure 1A The 304 stainless steel plate is combined with the Q235B continuous casting billet, and then the 304 stainless steel welding material is used for TIG welding. The two ends of the composite billet along the length direction are made of image 3 Closed by manual arc welding. The composite billet is heated to 1120°C, kept at a temperature of 4 hours, and rolled on a bar and wire continuous rolling line. Before 120mm, it is box-shaped hole rolling, and after that, it is ellipse-circle-ellipse hole rolling. The diameter of the finished product is 20mm, and a 304 stainless steel rod composite steel rod is obtained. A batch of 304 stainless steel composite steel rods ...

Embodiment 2

[0060] Except for selecting Q235B continuous casting billet (160mm×160mm) and 316L stainless steel plate (thickness 6mm) as the inner material and outer cladding layer, the remaining steps were the same as in Example 1 to obtain 316L stainless steel rod composite profiles. After inspection, the average thickness of the stainless steel cladding is 0.65mm, and the minimum thickness is 0.5mm.

Embodiment 3

[0070] 15MnVN low-alloy steel continuous casting rectangular billet (220mm×180mm) and 202 stainless steel plate (thickness 6mm) were selected as the inner material and outer cladding respectively. The stainless steel plates are cut into widths of 220mm and 180mm respectively, and after cleaning, Ni-Cr alloy is thermally sprayed on the surface to be compounded. The weight ratio of Ni to Cr alloy is 1:2, and the coating thickness is 0.1mm-0.15mm. according to Figure 1B 304 stainless steel welding consumables are used for TIG welding after splicing, and both ends are Figure 4 Disc soldering package in a way. The heating temperature is 1250°C, and the temperature is kept for 4 hours. The universal rolling mill is used to roll into H-shaped steel. The finished size of H-shaped steel is 582×510×30×25 (unit: mm), and air-cooled after rolling. After inspection, the stainless steel cladding at the flange and web position of the H-shaped steel cross section is 0.8 mm to 1.6 mm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com