A kind of vitrified microbead thermal insulation mortar

A technology of thermal insulation mortar and vitrified microbeads, which is applied in the construction field, can solve the problems of limited bonding ability of substrates, uneven performance, slow setting and hardening, etc., and achieve good thermal insulation, strong adhesion, and crack resistance The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

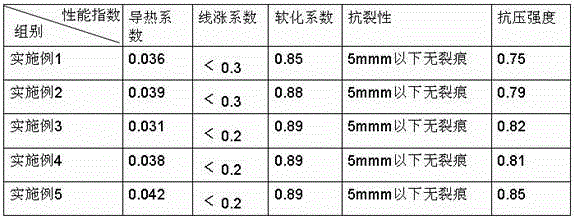

Examples

Embodiment 1

[0012] A vitrified microbead thermal insulation mortar, which is prepared according to a conventional thermal insulation mortar preparation method, and includes the following components in parts by weight: 40 parts of Portland cement, 25 parts of vitrified microspheres, 10 parts of carbon airgel, and light-burned magnesium oxide 1 part, 4 parts of diatomaceous earth, 1 part of polypropylene fiber, 1 part of acrylic elastic emulsion, 1 part of polypropylene alcohol, 1 part of cellulose ether, and 1 part of hydroxyethyl cellulose ether.

Embodiment 2

[0014] A vitrified microbead thermal insulation mortar, which is prepared according to a conventional thermal insulation mortar preparation method, and includes the following components in parts by weight: 65 parts of Portland cement, 35 parts of vitrified microspheres, 20 parts of carbon airgel, light-burned magnesium oxide 3 parts, 9 parts of diatomaceous earth, 3 parts of polypropylene fiber, 4 parts of acrylic elastic emulsion, 2 parts of polypropylene alcohol, 3 parts of cellulose ether, and 3 parts of hydroxyethyl cellulose ether.

Embodiment 3

[0016] A vitrified microbead thermal insulation mortar, which is prepared according to a conventional thermal insulation mortar preparation method, comprising the following components in parts by weight: 45 parts of Portland cement, 28 parts of vitrified microspheres, 13 parts of carbon airgel, and light-burned magnesium oxide 2 parts, 5 parts of diatomaceous earth, 1 part of polypropylene fiber, 2 parts of acrylic elastic emulsion, 1 part of polypropylene alcohol, 1 part of cellulose ether, and 2 parts of hydroxyethyl cellulose ether.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com