A kind of sound insulation material for building and preparation method thereof

A sound insulation material and technology for construction, applied in the field of building materials, can solve the problems of unsatisfactory sound insulation performance and poor environmental protection, and achieve the effects of various molding methods, convenient coloring, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

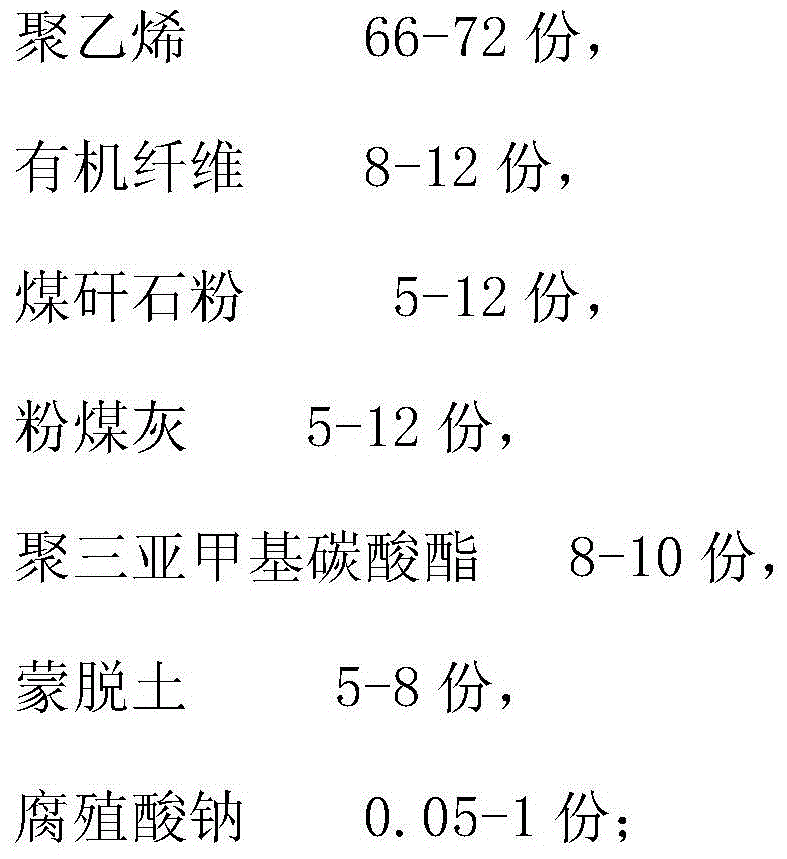

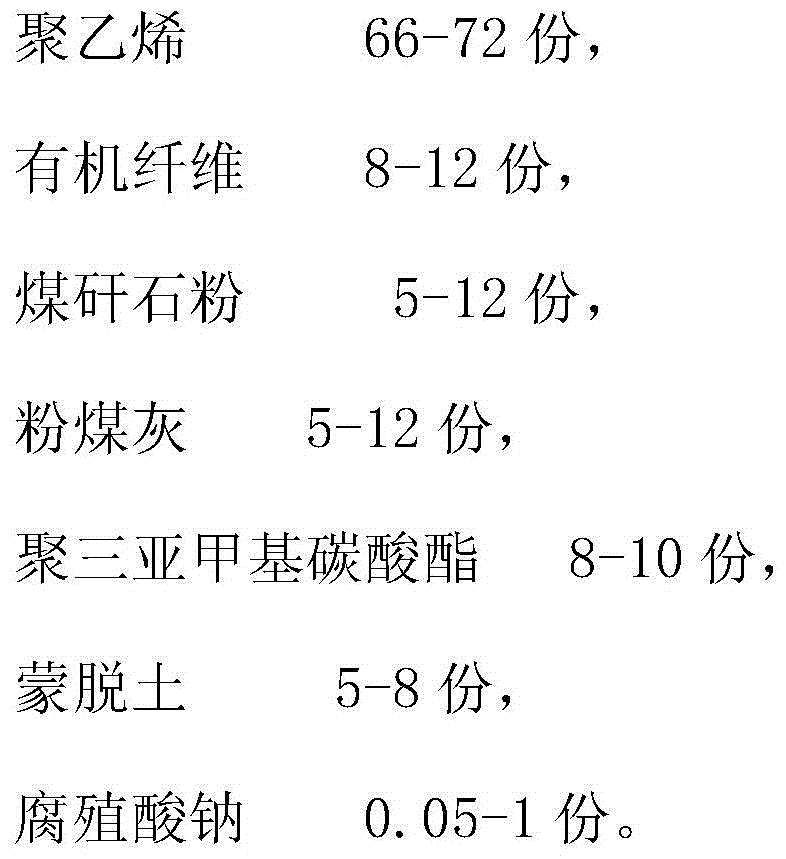

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh high-density polyethylene 22kg, low-density polyethylene 44kg, polyethylene terephthalate fiber 4kg, polyphenylene sulfide fiber 4kg, coal gangue powder 12kg, fly ash 5kg, polytrimethylene Carbonate 10kg and montmorillonite 5kg;

[0023] (2) Add the above components into a high-pressure homogenizer, and stir for 30 minutes at 21.5MPa and 65°C;

[0024] (3) Add 0.05 kg of sodium humate, stir evenly, and fire at 780° C. for 2 hours to obtain a sound-insulating material for construction.

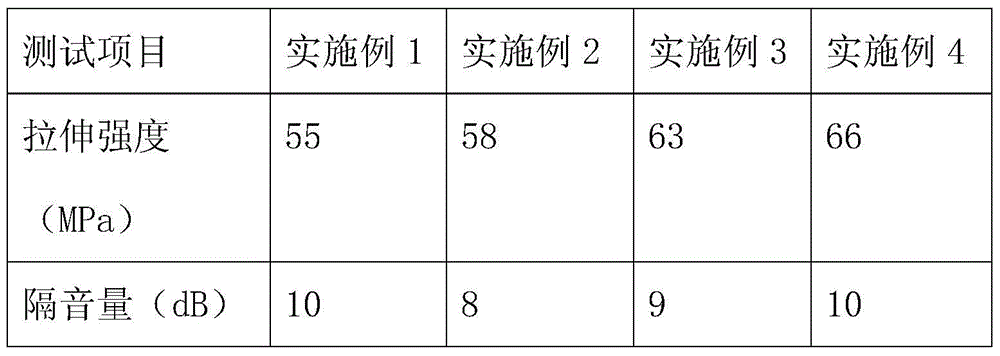

[0025] The performance test results of the prepared building sound insulation materials are shown in Table 1.

Embodiment 2

[0027] (1) Weigh 24kg of high-density polyethylene, 48kg of low-density polyethylene, 6kg of polyethylene terephthalate fiber, 6kg of polyphenylene sulfide fiber, 5kg of coal gangue powder, 12kg of fly ash, polytrimethylene Carbonate 10kg and montmorillonite 8kg;

[0028] (2) Add the above components into a high-pressure homogenizer, and stir at 22MPa and 70°C for 30min;

[0029] (3) Add 1 kg of sodium humate, stir evenly, and fire at 800° C. for 3 hours to obtain a sound-insulating material for construction.

[0030] The performance test results of the prepared building sound insulation materials are shown in Table 1.

Embodiment 3

[0032] (1) Weigh 23kg of high-density polyethylene, 46kg of low-density polyethylene, 5kg of polyethylene terephthalate fiber, 5kg of polyphenylene sulfide fiber, 8kg of coal gangue powder, 8kg of fly ash, polytrimethylene Carbonate 8kg and montmorillonite 8kg;

[0033] (2) Add the above components into a high-pressure homogenizer, and stir at 21.5MPa and 70°C for 30min;

[0034] (3) Add 0.5 kg of sodium humate, stir evenly, and fire at 850° C. for 2 hours to obtain a sound-insulating material for construction.

[0035] The performance test results of the prepared building sound insulation materials are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com