System and method for calcining cement clinker through lignite safely in large amount

A technology for cement clinker and lignite, applied in separation methods, chemical instruments and methods, inert gas generation, etc., can solve the safety hazards of grinding lignite, the existence of explosion safety hazards, and reduce nitrogen oxide emissions. performance, improve safety, and reduce the chance of spontaneous combustion of pulverized coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

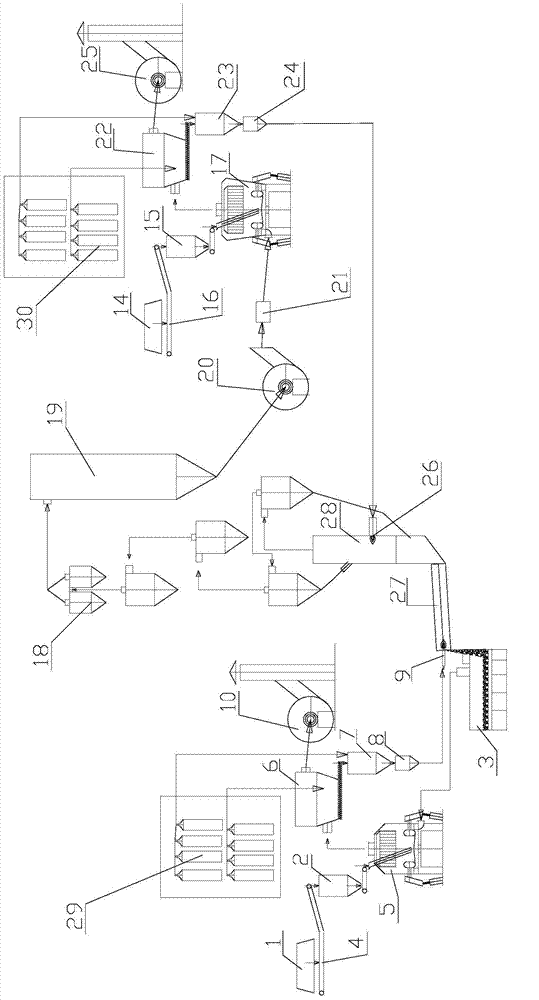

[0025] Embodiment 1: A system for calcining cement clinker using lignite, which includes a raw coal grinding system at the kiln head and a raw coal grinding system at the kiln tail.

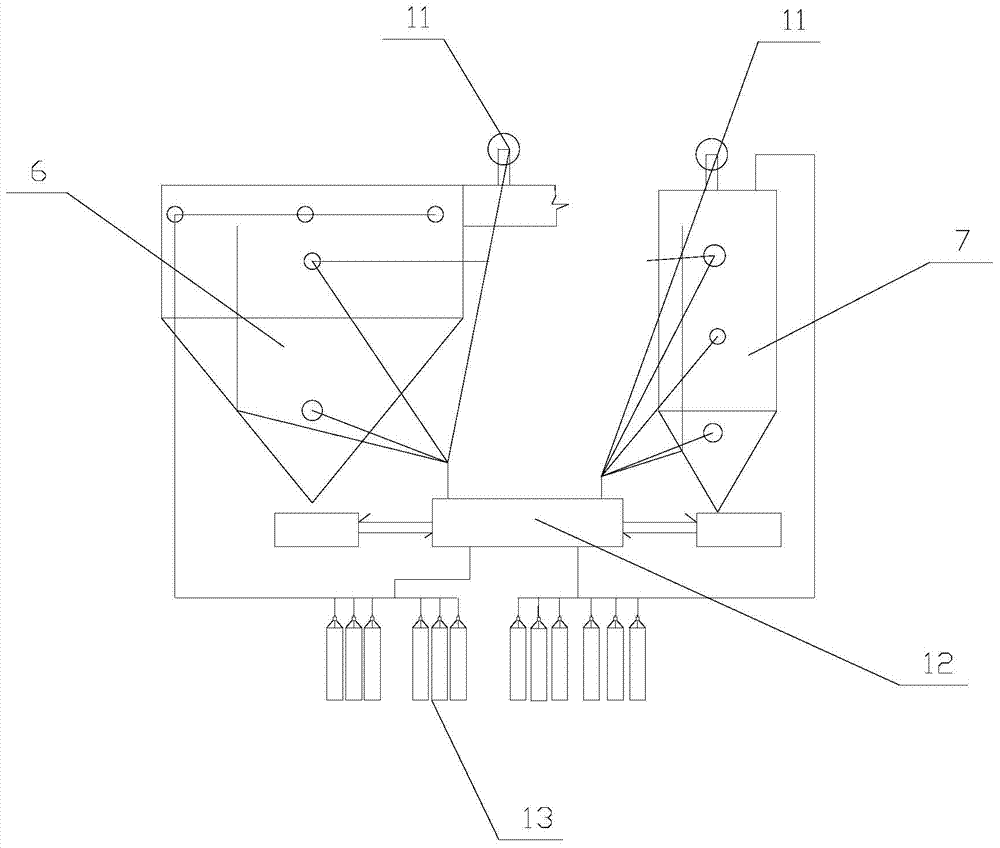

[0026] The kiln head raw coal grinding system includes a kiln head coal storage yard 1, a kiln head coal raw coal bunker 2, a clinker grate cooler 3, a kiln head coal quantitative feeder 4, a standard configuration mill 5, and a kiln head coal mill Pulse bag filter 6, kiln head coal powder warehouse 7, kiln head coal powder scale 8, kiln head burner 9, kiln head coal mill exhaust fan 10 and kiln head carbon dioxide explosion-proof device 29; kiln head coal storage yard 1 passes through the conveyor belt It is connected with the inlet of kiln head raw coal bunker 2, the outlet of kiln head coal raw coal bunker 2 is connected with the inlet of kiln head coal quantitative feeder 4, and the outlet of kiln head coal quantitative feeder 4 is in line with the standard The feed port of the configuration ...

Embodiment 2

[0028] Embodiment 2: A method of using lignite to calcinate cement clinker. After grinding bituminous coal or anthracite through the kiln head raw coal grinding system, add it to the kiln head burner 9 as coal for the rotary kiln 27; After the pulverized coal is pulverized, it is added to the kiln tail burner 26 as coal for the calciner 28 .

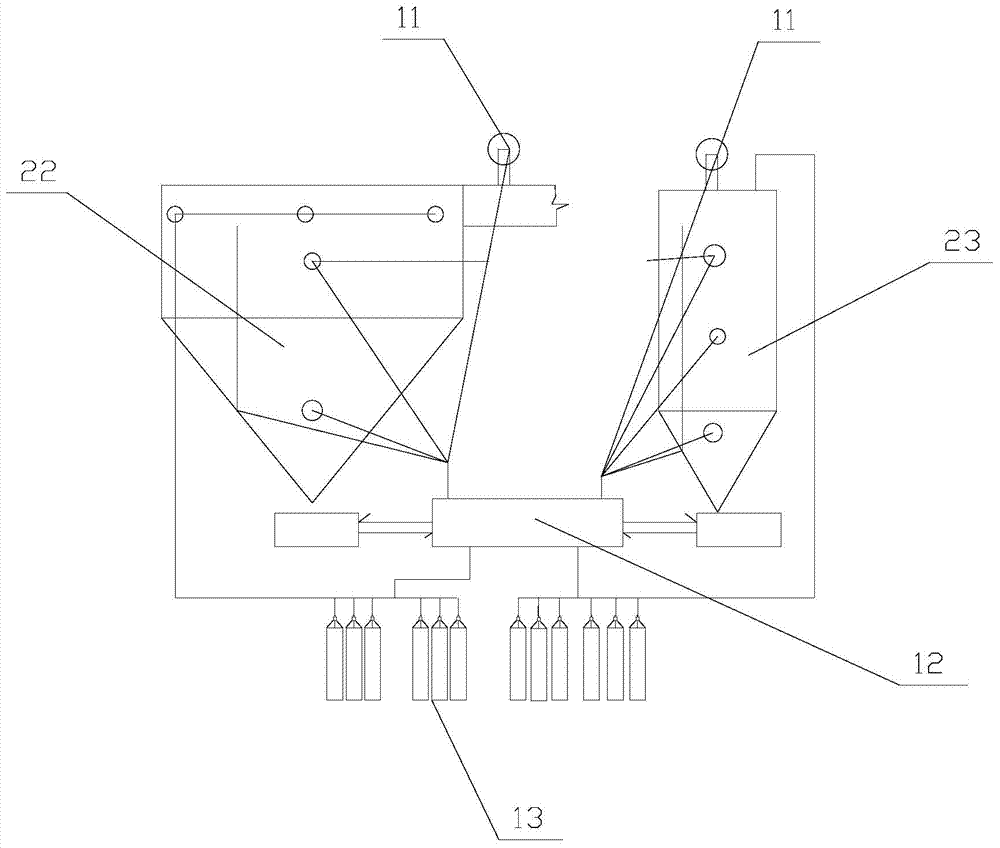

[0029] Wherein, grinding lignite with the kiln tail raw coal grinding system specifically includes the following steps: (1) sending the lignite in the kiln tail coal raw coal bunker 15 into the special mill at 15-22 tons per hour through the kiln tail coal quantitative feeder 16 Grinding in the machine 17; during the start or stop of the special mill 17, by adjusting the coal feed rate of the kiln tail coal quantitative feeder 16, ensure that the gas temperature at the outlet of the special mill 17 is within the range of 45-70°C; Adjust the hot air valve between the high temperature fan 20 and the kiln tail coal mill cyclone dust collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com