Method for manufacturing graphene gain coupling distributive feedback type silica based mixing laser

A distributed feedback and hybrid laser technology, which is applied to lasers, laser components, semiconductor lasers, etc., can solve problems such as material lattice mismatch, and achieve low scattering loss, simple process, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

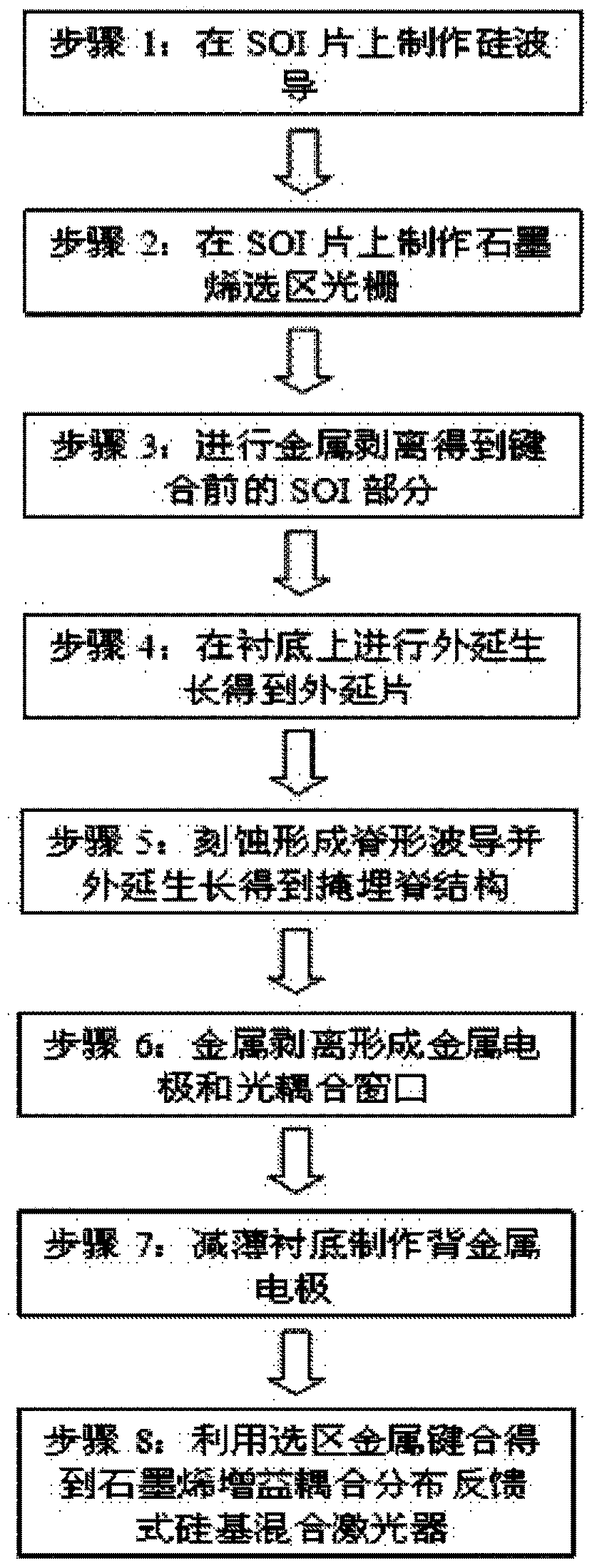

[0026] see figure 1 and refer to Figure 2-Figure 8 As shown, a method for manufacturing a graphene gain-coupled distributed feedback silicon-based hybrid laser of the present invention is described in detail. The specific implementation plan is introduced below:

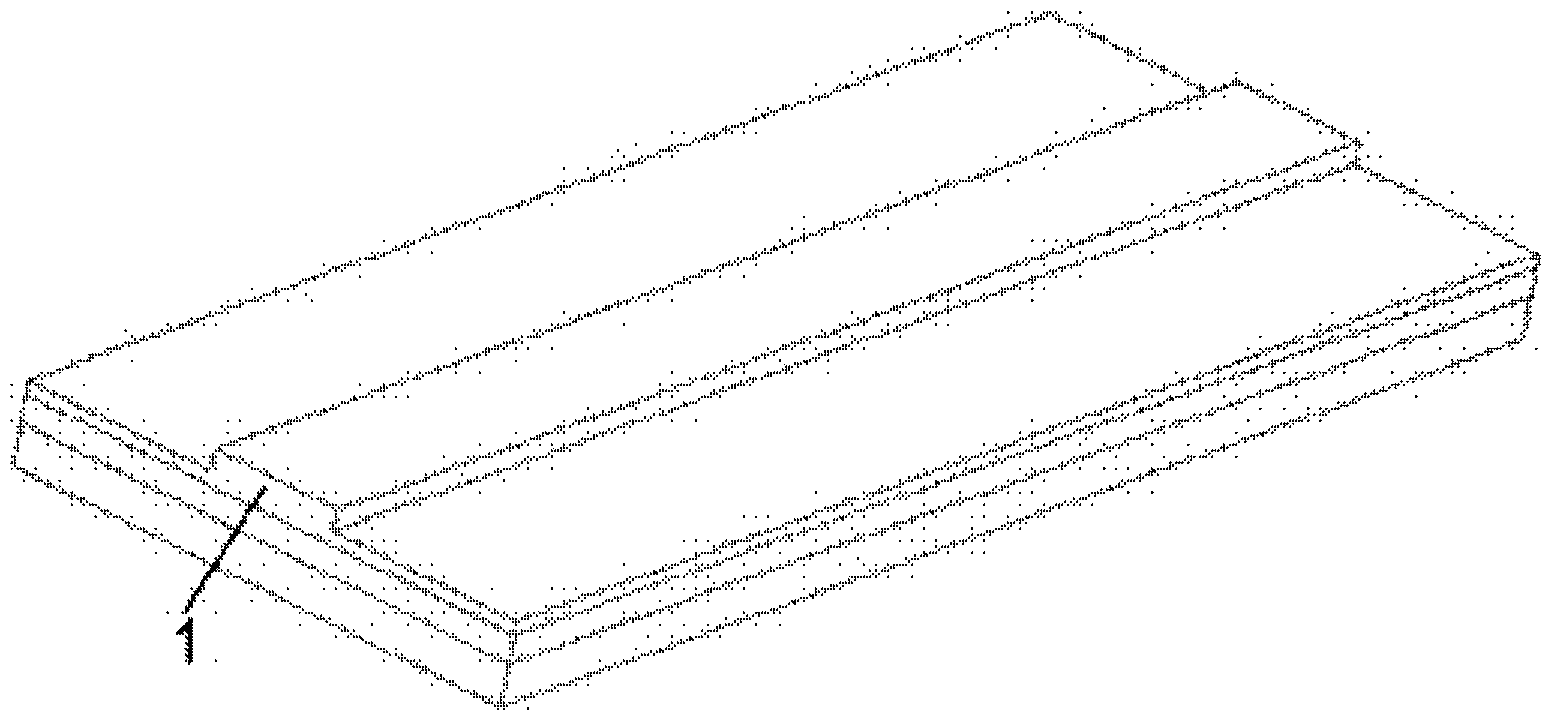

[0027] Step 1: Fabricate a silicon waveguide 1 on the top silicon layer of the SOI sheet by inductively coupled plasma etching (ICP), wherein the silicon waveguide has a width of 2 μm-5 μm and a height of 120nm-500nm, such as figure 2 shown;

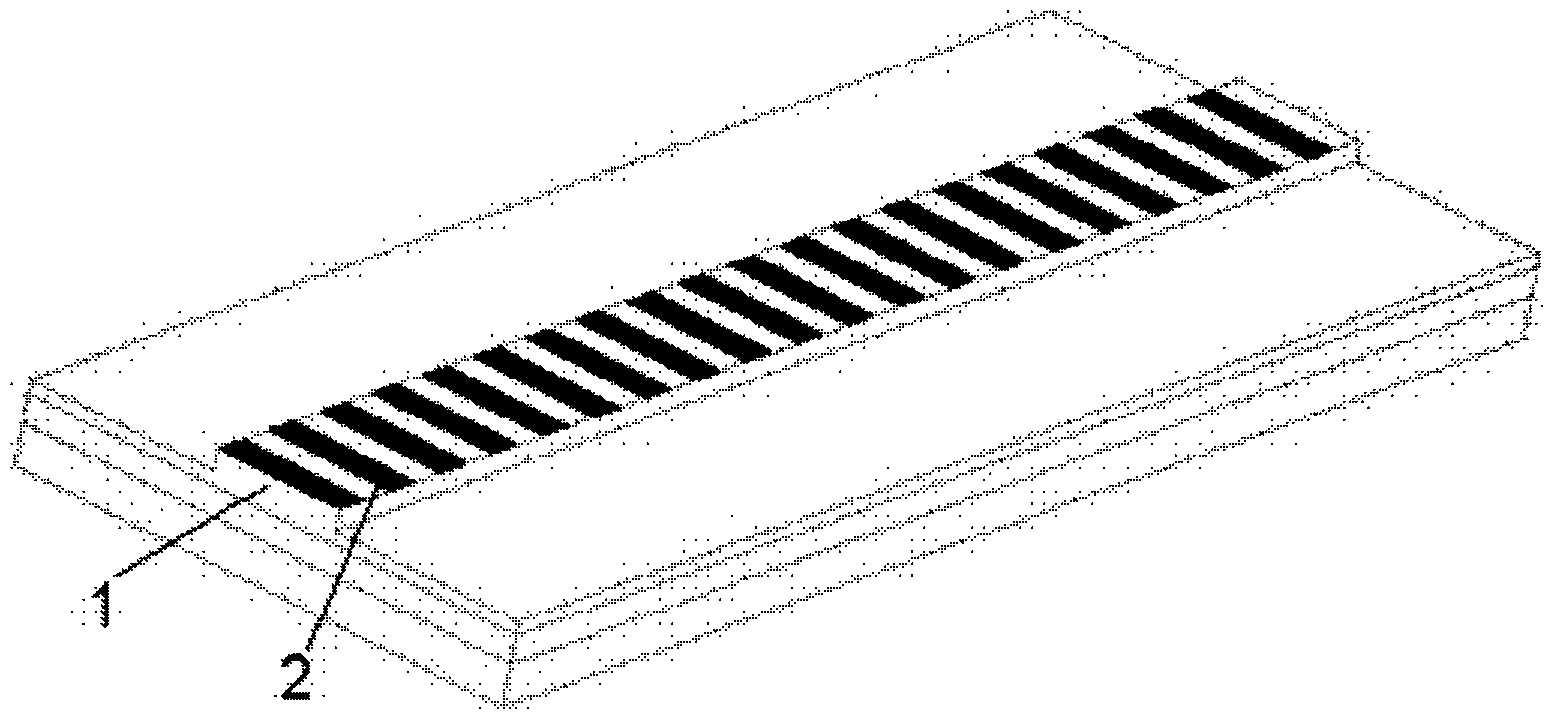

[0028] Step 2: Transfer large-area graphene to the SOI sheet after the silicon waveguide 1 is completed, and the number of transferred graphene layers is 1-5 layers. Calculation of the effective refractive index n of a graphene gain-coupled distributed feedback laser using finite-difference time-domain (FDTD) software eff , given the target wavelength λ, into the formula Λ = λ / 2n eff , to obtain the period Λ of the graphene grating. On the graphene-covered SOI sheet, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com