Membrane wall tube inner wall corrosion failure critical judging method

A membrane-type water-cooling wall and determination method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of resource waste, wall thickness difference, pipeline strength difference, etc., to ensure safe operation and save replacement. Quantity, on-site implementation of simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

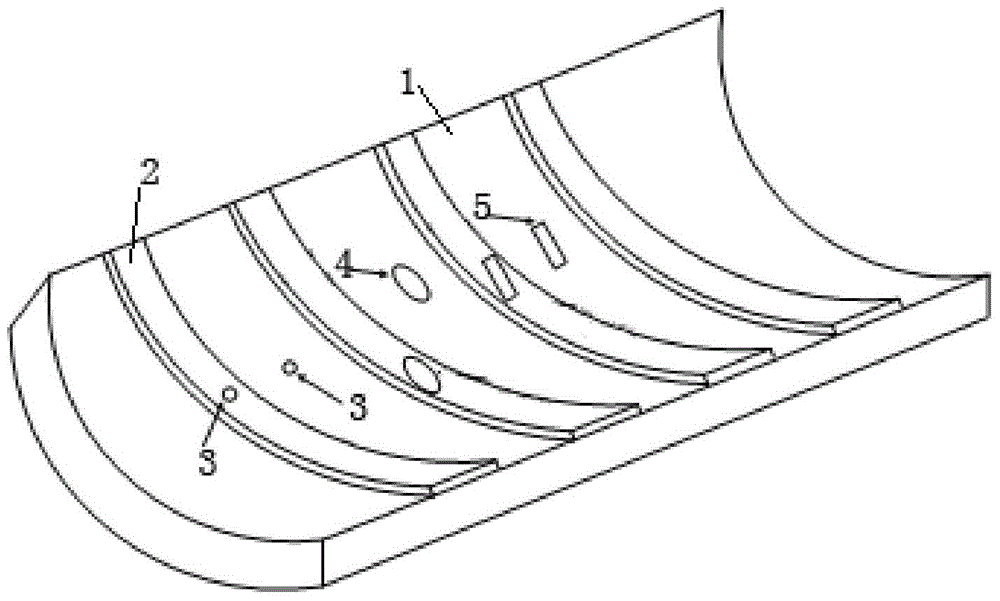

[0031] The invention is mainly used to solve the problem of judging the corrosion failure criticality (equivalent stress is equal to the safety check strength) of the inner wall of the membrane-type water-cooled wall tube of the 300MW thermal power unit. The membrane-type water-cooled wall tube with corrosion on the inner wall cannot be evaluated by conventional methods. Whether it is in a critical state of failure, and it is necessary to replace a full range of pipelines at the position where the inner wall is corroded, resulting in the removal of a large number of pipelines that can still be used safely, resulting in a waste of resources, and forming multiple new welds during the replacement process, bringing new safety risk. By adopting the present invention, a systematic method for judging the corrosion degree of the inner wall of the water-cooled wall pipe can be formed, thereby judging the critical state of material failure, and according to the inspection result, targete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com