Aircraft tyre driver with energy recovery function

An aircraft tire and energy recovery technology, which is applied in the direction of aircraft brake arrangement, wheel type, and control mechanism, can solve the problems of increased rubber hysteresis loss, endangering passenger safety, and falling blocks, and achieves the effect of reducing wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

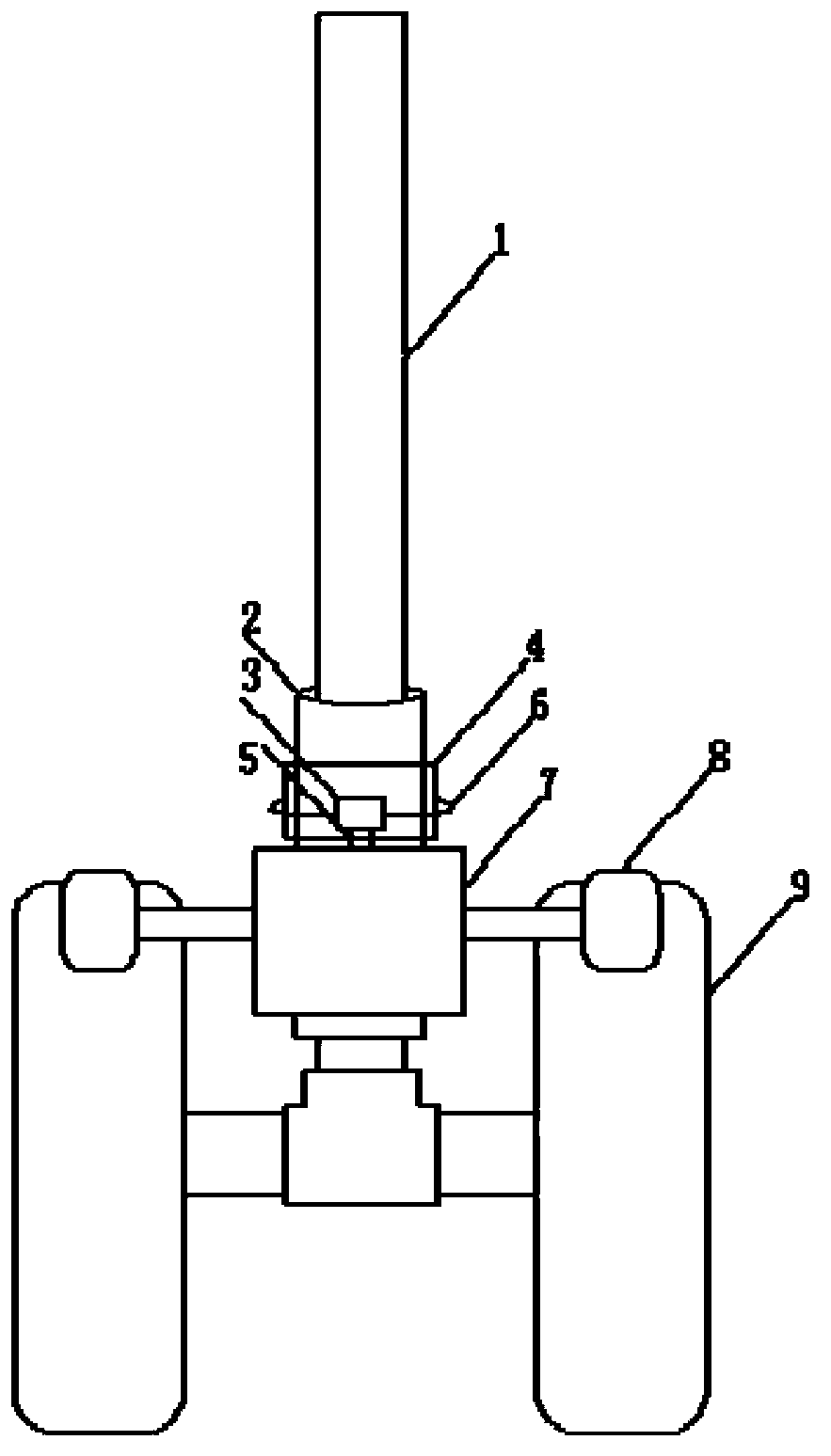

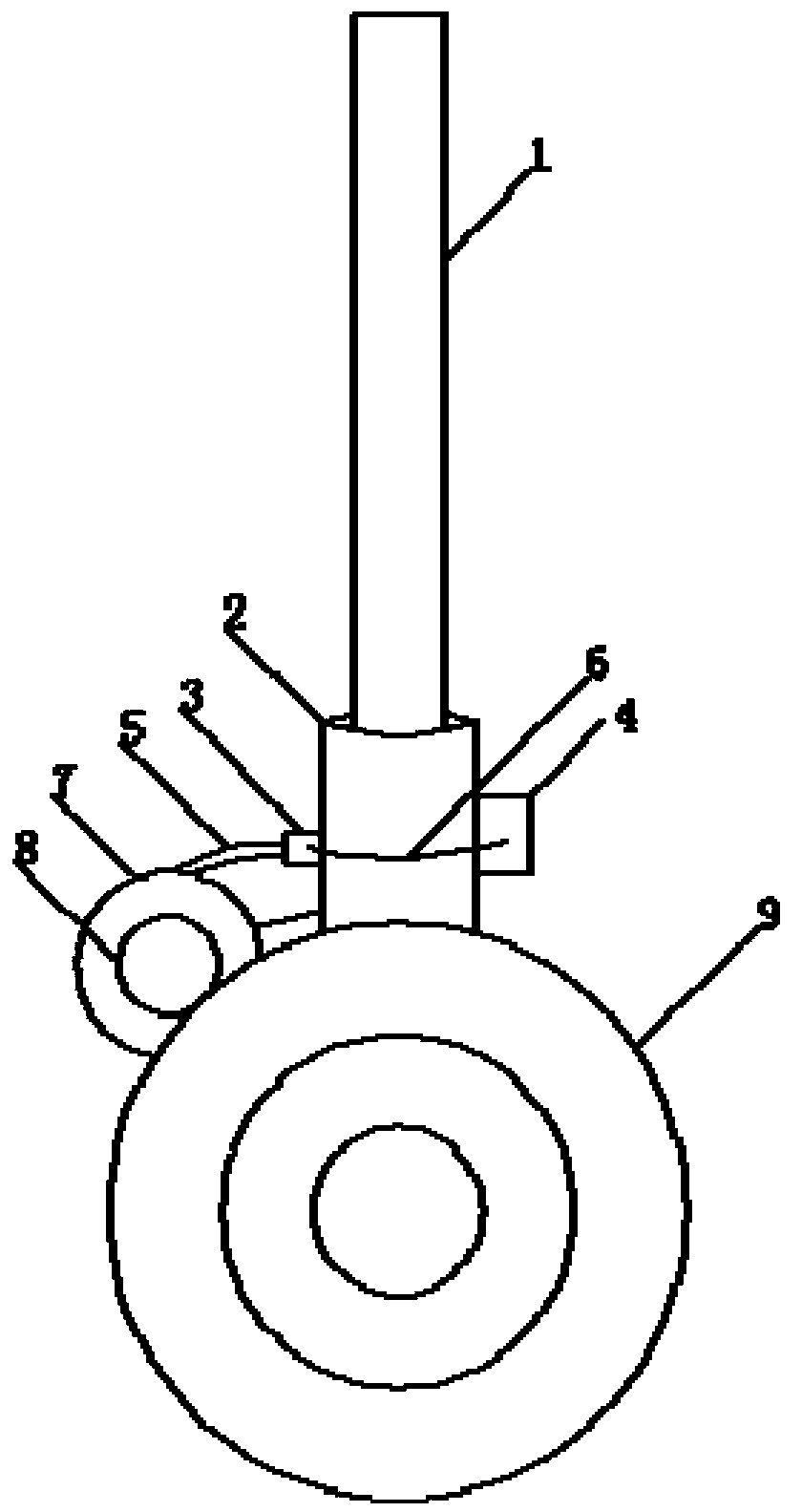

[0012] The aircraft tire driver with energy recovery function of the present invention, such as figure 1 , figure 2 As shown, the driver is mainly composed of a fixed ring 2, a rectifier 3, a battery 4, a rectifier line 5, a charging line 6, a motor 7 and a friction wheel 8, and is installed on the landing gear 1 of the aircraft through the fixed ring 2, and the motor of the driver 7 is connected to the rectifier 3 through two rectifying wires 5 of positive and negative poles, the rectifier 3 is connected to the battery 4 through the charging wire 6, the shaft of the motor 7 is connected to the friction wheel 8 through a key and drives the friction wheel 8 to rotate, and the friction wheel 8 and the Tire 9 is in contact state all the time.

[0013] When the aircraft is preparing to land, first put down the landing gear 1, and now the battery 4 starts to supply power to the motor 7. After the stator winding inside the motor 7 reaches the rated voltage, the shaft of the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com