An optical fiber liquid level sensor and its measuring method

A liquid level sensor and measurement method technology, applied in the field of sensors, can solve the problems of difficult manufacturing of deformed teeth, expensive wavelength demodulation equipment, etc., and achieve the effect of good electromagnetic anti-interference performance, cheap price, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

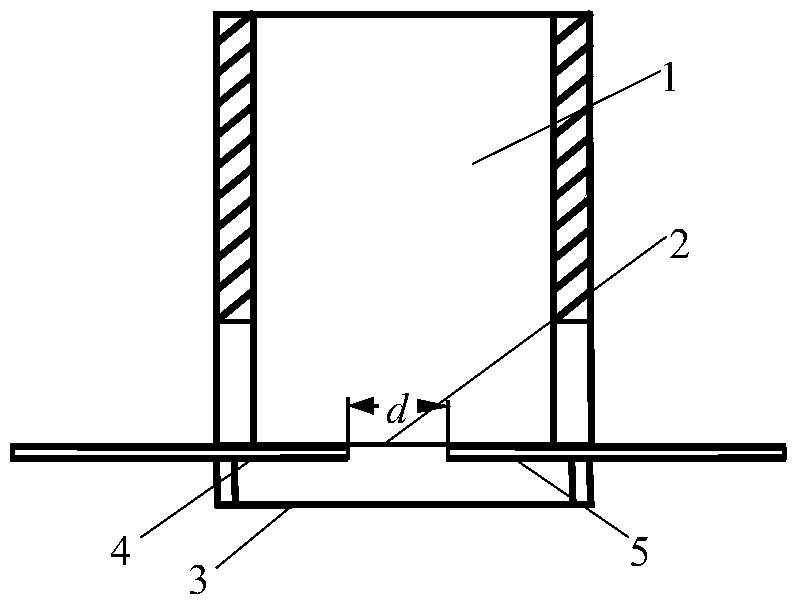

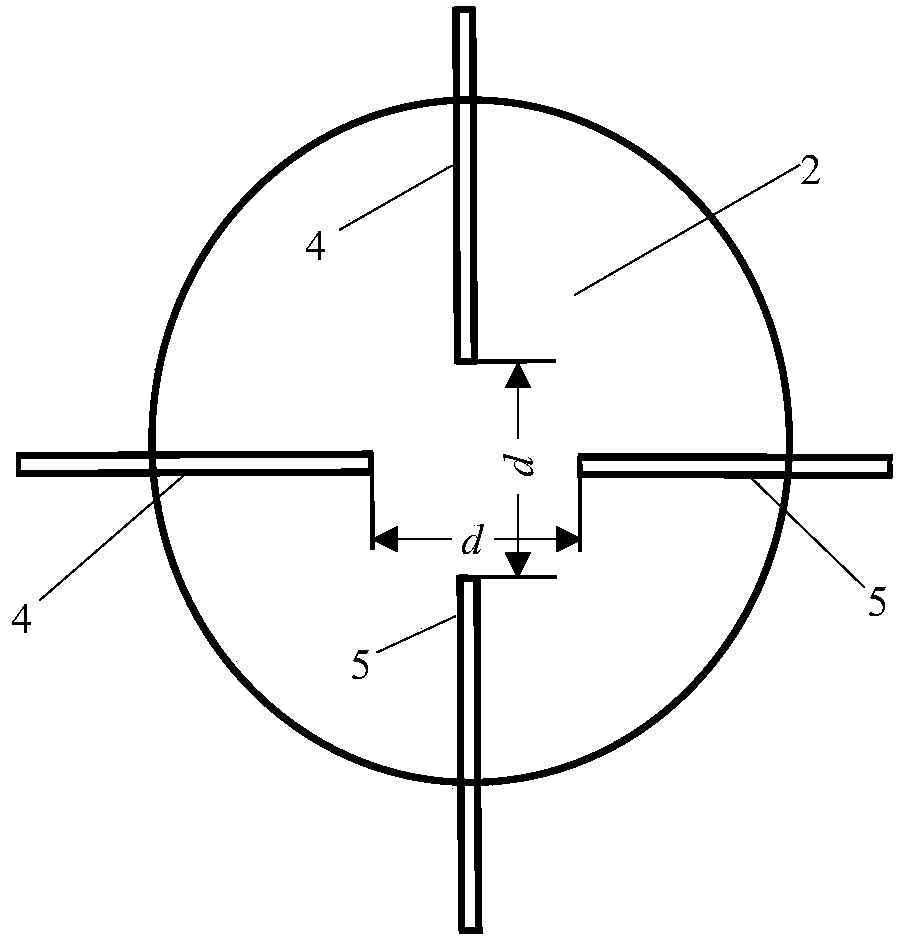

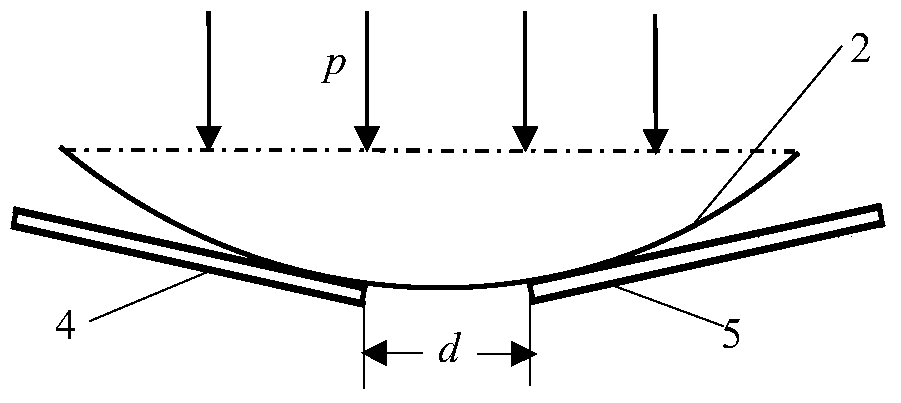

[0068] The structure of the optical fiber liquid level sensor is as follows: figure 1 As shown, it mainly consists of an elastic disc 2, a threaded cylinder 1 and two sections of optical fibers. From figure 1 It can be seen from the figure that two sections of the same optical fiber, the incident optical fiber 4 and the receiving optical fiber 5, are symmetrically pasted on the diameter of the elastic disc 2, and the distance is d, and the elastic disc 2 is pasted on the bottom of the threaded cylinder 1 , The outer wall of the threaded cylinder 1 is provided with threads. Such as figure 2 As shown, when the incident optical fiber and the receiving optical fiber are divided into two groups, the two incident optical fibers are distributed perpendicular to each other, and the two receiving optical fibers are distributed perpendicular to each other, which can avoid the incident when the optical fiber liquid level sensor is not placed horizontally in the liquid The vertical ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com