Manufacturing and construction method of air bag type concrete engineering deformation joint water stop type cavity die

A technology of concrete and deformation joints, which is applied in sea area engineering, earthwork drilling and mining, water conservancy projects, etc. It can solve the problems of prolonging construction period, increasing labor, and running of soft asphalt, and achieves the effect of convenient pouring, saving construction period and convenient demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, with reference to the accompanying drawings: a method for manufacturing an airbag-type concrete engineering deformation joint waterproof cavity mold, the cavity mold includes a skeleton 1 and an airbag, and is characterized in that it includes the following processes and steps:

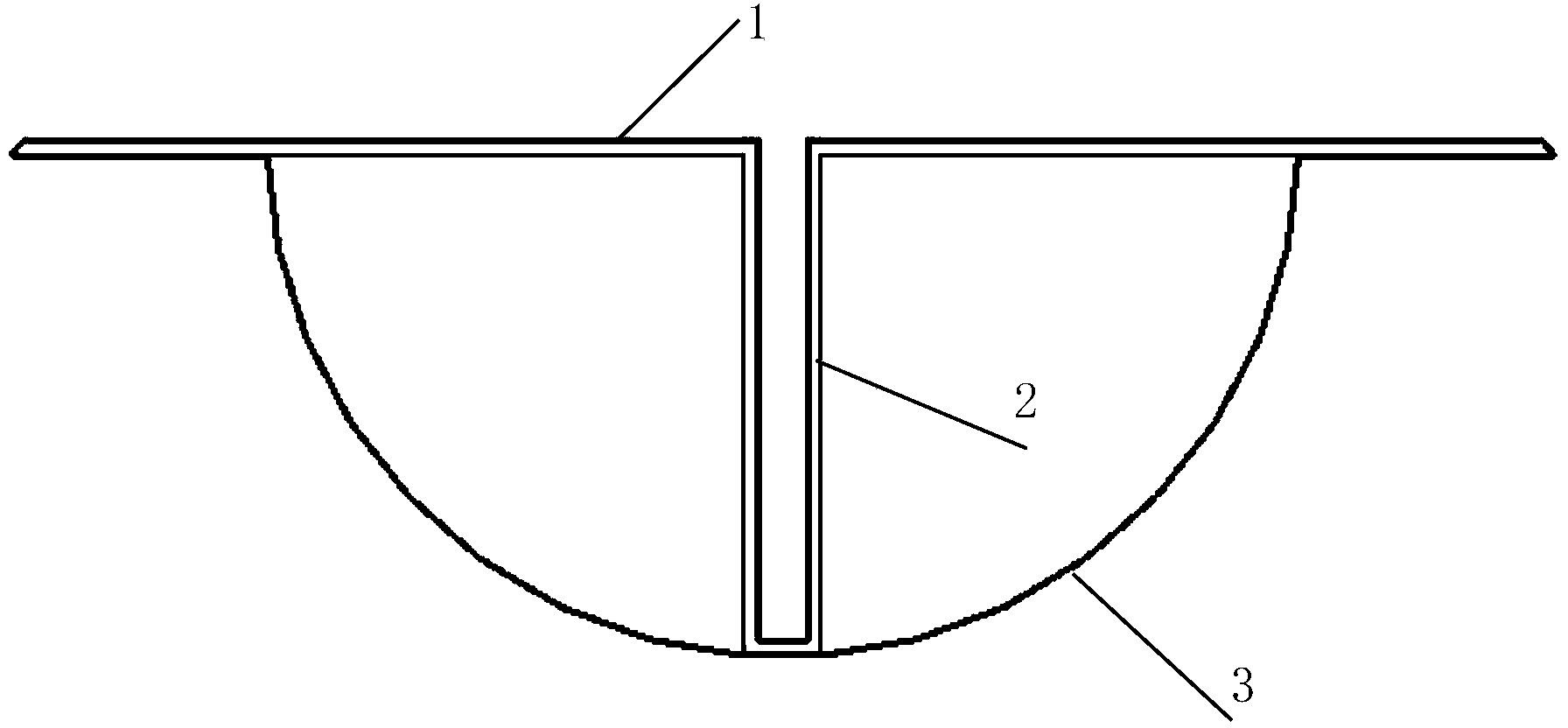

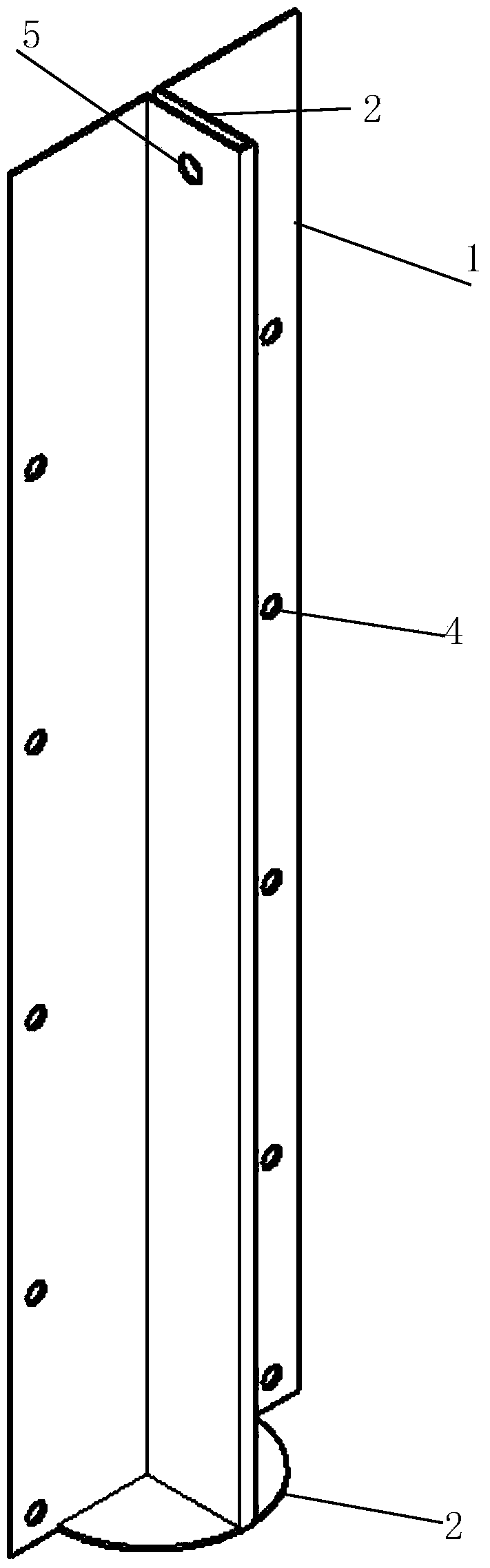

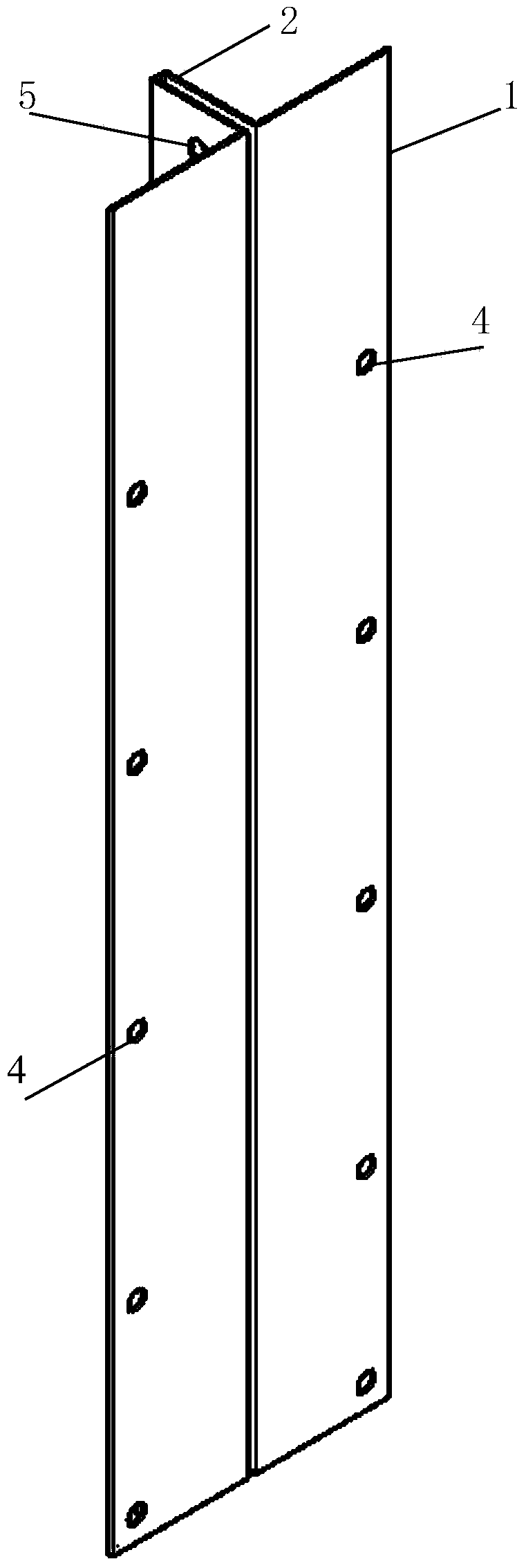

[0042]1) Fabrication of frame 1: frame 1 is a rectangular steel plate with a thickness of 2-4mm and a length greater than the height of the deformation joint by 20-40cm. A groove 2 is folded or welded in the middle, and the depth of the groove 2 is 15-30cm. Groove 2 width 5-10cm, framework 1 contains groove 2 width 30-50cm, fixation holes 4 are set at a certain distance longitudinally on both sides of framework 1, hanging holes 8 are set on the upper end groove 5 of framework 1, and The lower end of 1 is provided with a base 3, the radius of the base 3 is equal to the depth of the groove 2, and the two sides of the skeleton 1 are provided with 45° chamfering;

[0043] 2) Airbag pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

| Groove width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com