Anti-electromagnetic radiation glue used for carbon crystal and carbon fiber electronic heaters and preparation method

An anti-electromagnetic radiation and electronic heating technology, which is applied in ohmic resistance heating parts, non-polymer adhesive additives, adhesives, etc., can solve problems such as endangering human health, and achieve the effects of reducing radiation, tight shielding, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

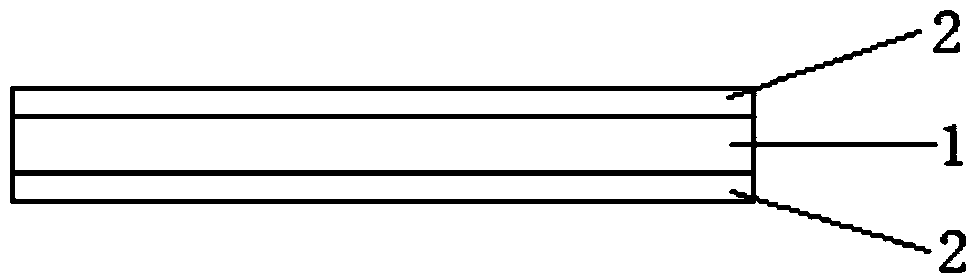

Image

Examples

preparation example Construction

[0026] The preparation method of above-mentioned anti-electromagnetic radiation glue is characterized in that, comprises the following steps:

[0027] Step 1: Weigh the following components according to mass percentage: epoxy resin 20%-50%, conductive carbon powder 10%-20%, graphite 5%-10%, tourmaline 10%-20%, copper powder 5% %~10%, nickel powder 5%~10%, dicyandiamide 1%~3%, magnesium hydroxide 9%~12%, the sum of the mass percentages of the above components is 100%;

Embodiment 1

[0036] Step 1: Weigh the following components respectively: 20g of epoxy resin (E20), 20g of conductive carbon powder, 10g of graphite, 20g of tourmaline, 10g of copper powder, 10g of nickel powder, 1g of dicyandiamide, and 9g of magnesium hydroxide;

[0037] Step 2: Add the epoxy resin and curing agent weighed in step 1 into the reactor, and add acetone with a total mass of each component of 100% to dissolve, and then add conductive carbon powder, tourmaline, and magnesium hydroxide to the reactor in turn , and add graphite, copper powder, nickel powder, stir evenly, use sm-12 type coating machine to coat the surface of carbon crystal electronic heating plate, the thickness of coating is more than 10μm, and then solidify at 150℃ for 2h to form Electromagnetic radiation shielding and adsorption layer.

[0038] After adding the anti-electromagnetic radiation coating, the electromagnetic radiation can be reduced to 0.8 μΤ.

Embodiment 2

[0040] Step 1: Weigh the following components respectively: 50g of epoxy resin (E51), 10g of conductive carbon powder, 5g of graphite, 10g of tourmaline, 5g of copper powder, 5g of nickel powder, 3g of dicyandiamide, and 12g of magnesium hydroxide;

[0041] Step 2: Add the epoxy resin and curing agent weighed in step 1 into the reactor, and add acetone with a total mass of 200% of each component to dissolve, and then add conductive carbon powder, tourmaline, and magnesium hydroxide to the reactor in turn , and add graphite, copper powder, nickel powder, stir evenly, use sm-12 type coater to coat the surface of carbon fiber electronic heating plate, the thickness of the coating is more than 15μm, and then cure at 180°C for 0.5h to form Electromagnetic radiation shielding and adsorption layer.

[0042] After adding the anti-electromagnetic radiation coating, the electromagnetic radiation can be reduced to 0.73 μΤ.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com