Method for preparing chloride metallocene polypropylene by acid-phase emulsion melting process

A technology of metallocene polypropylene and chlorinated metallocene, applied in the field of acid phase emulsion melting method to prepare chlorinated metallocene polypropylene, which can solve the problems of inability to achieve solubility and inability to break the crystallinity of polypropylene, so as to avoid environmental pollution Problems, cost reduction, effect of improving chlorination uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

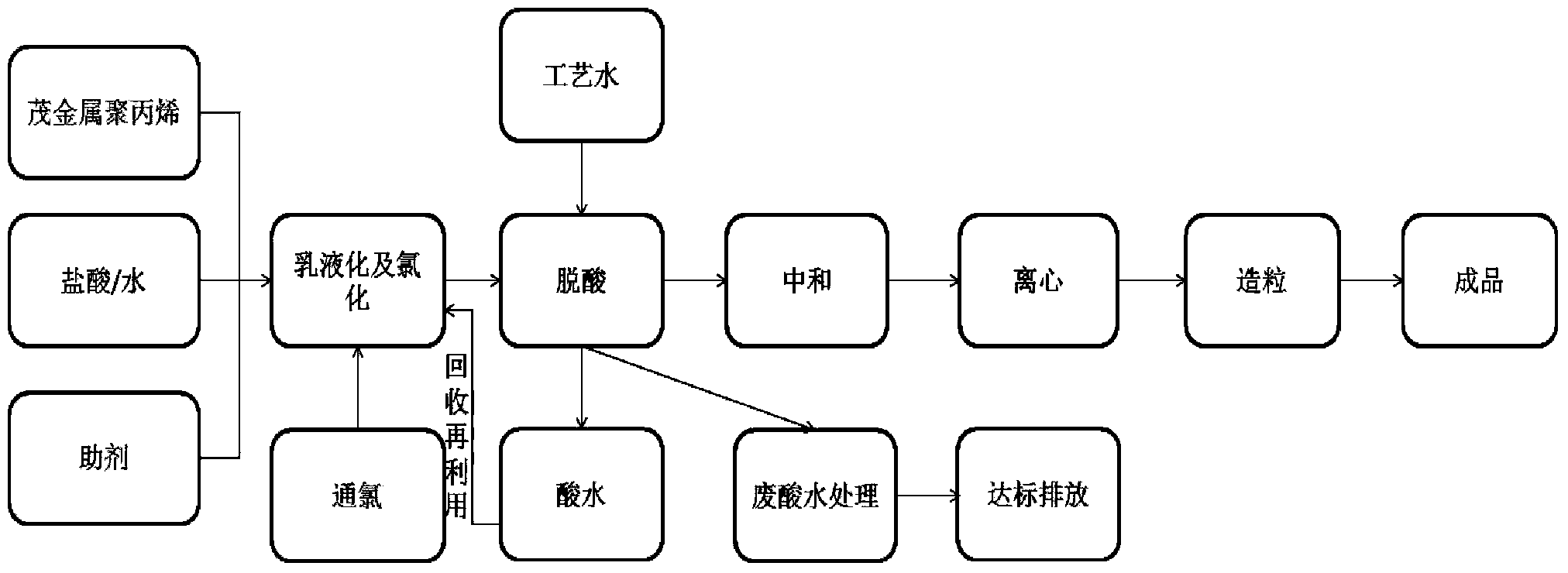

[0047] In the present embodiment, the method for preparing chlorinated metallocene polypropylene by acid phase emulsion melting method, the chlorination process is initiated by adding an initiator, including the following steps:

[0048] 1) Emulsification chlorination reaction

[0049] Add 80 liters of hydrochloric acid solution with a mass concentration of 30% into the reactor, start stirring, add 2Kg of fatty acid polyethylene glycol ester, 2Kg of polyoxyethylene ether and 5Kg of metallocene polypropylene particles, open the steam valve of the reactor to heat up and emulsify, Add 200g of benzoyl peroxide when the temperature in the reactor rises to 75-80°C, close the reactor, and start feeding liquid chlorine when the temperature in the reactor rises to 90°C, and control the temperature in the reactor to 90-130°C. As the amount of chlorine increases, the temperature of the materials in the reactor also increases. Controlling the reaction temperature is a key factor for the s...

Embodiment 2

[0053] In the present embodiment, the method for preparing chlorinated metallocene polypropylene by acid phase emulsion melting method, the chlorination process is initiated by adding an initiator, including the following steps:

[0054] 1) Emulsification chlorination reaction

[0055] Add 75 liters of hydrochloric acid solution with a mass concentration of 20% into the reactor, start stirring, add 1.5Kg of sodium polymethacrylate, 2Kg of castor oil epoxy ethyl ethers and 5Kg of metallocene polypropylene particles, and open the steam valve of the reactor Heating and emulsification, when the temperature in the reactor rises to 75-80°C, add 150g of azobisisobutylamidine hydrochloride, close the reactor, and start feeding liquid chlorine when the temperature of the reactor rises to 90°C, and control the temperature in the reactor. The temperature is 90-130°C. As the amount of chlorine increases, the temperature of the materials in the reactor also increases. Controlling the reac...

Embodiment 3

[0059] In the present embodiment, the method for preparing chlorinated metallocene polypropylene by acid phase emulsion melting method, the chlorination process is initiated by adding an initiator, including the following steps:

[0060] 1) Emulsification chlorination reaction

[0061] Add 85 liters of hydrochloric acid solution with a mass concentration of 25% into the reactor, start stirring, add 2.5Kg of polyvinylpyrrolidone, 3Kg of polyoxyethylene ether and 5Kg of metallocene polypropylene particles, and open the steam valve of the reactor to heat up and emulsify. Add 180g of azobisisobutyronitrile when the temperature in the kettle rises to 75-80°C, close the reaction kettle, and start feeding liquid chlorine when the temperature in the kettle rises to 90°C, and control the temperature in the reaction kettle to 90-130°C. As the amount of chlorine increases, the temperature of the materials in the reactor also increases. Controlling the reaction temperature is a key factor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com