Dirt dispersion agent for processing wastewater with high phosphorus content and high calcium content by using activated sludge

A technology of scale inhibitor and dispersant and activated sludge, which is applied in the field of scale inhibitor and dispersant, can solve problems such as the influence of the normal operation of the biological treatment system, and achieve the effects of long duration of drug effect, good stability and good biological activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

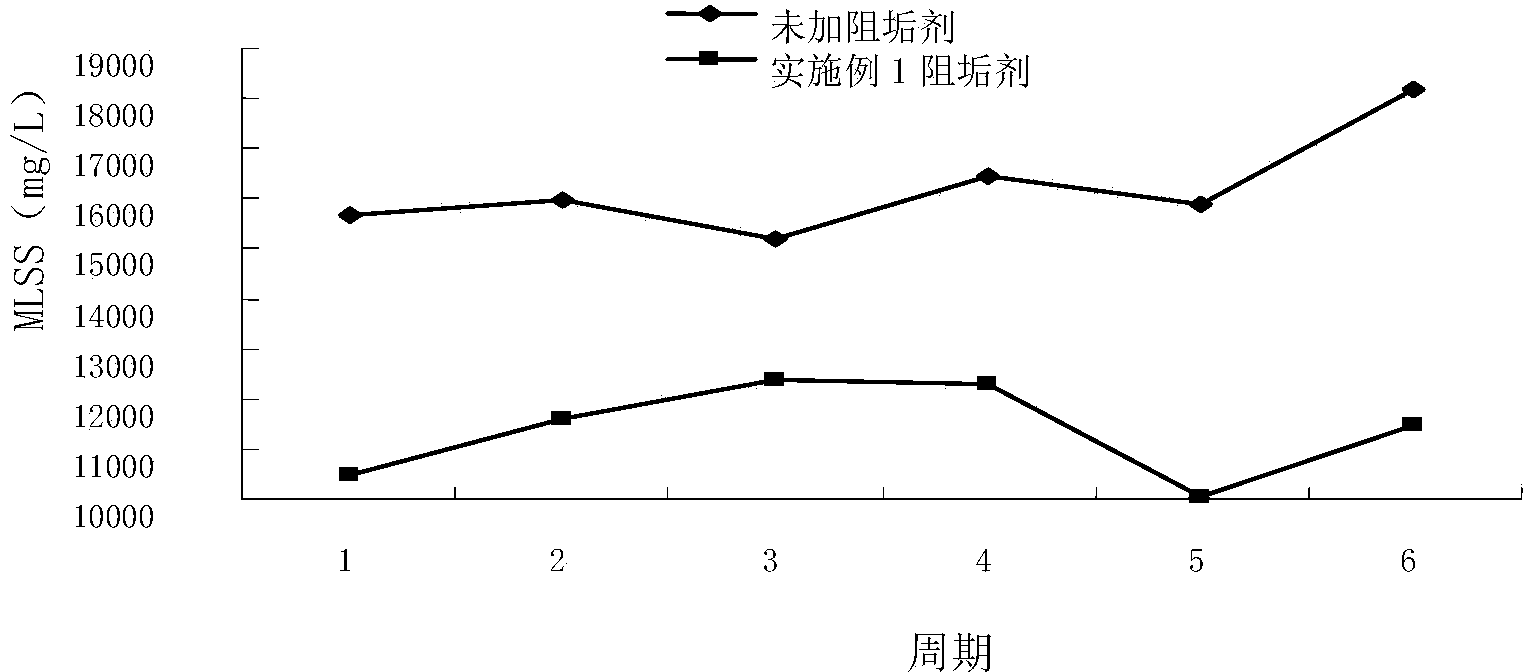

Embodiment 1

[0017] Take 15 parts by weight of acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, 15 parts by weight of 2-phosphonobutane-1,2,4-tricarboxylic acid, polyamino polyether group methylene phosphine 15 parts by weight of acid polycarboxylic acid are prepared by mixing and stirring.

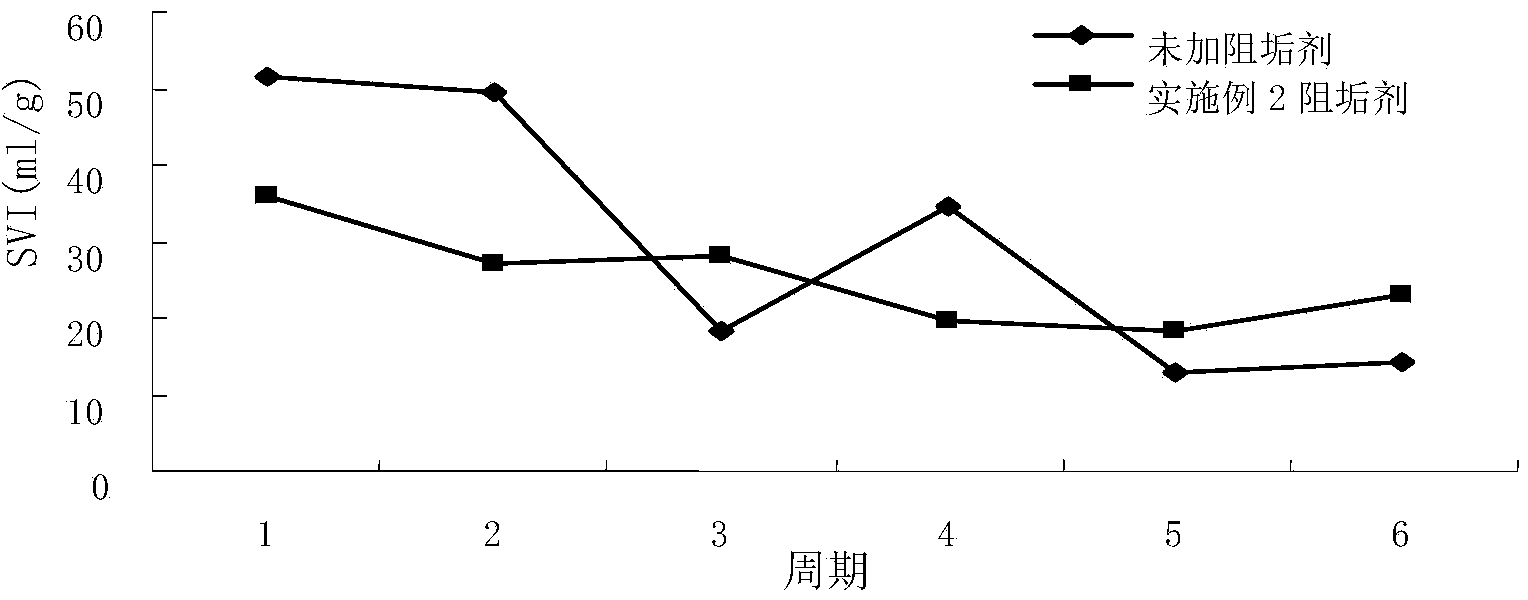

Embodiment 2

[0019] Take 19 parts by weight of acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, 12 parts by weight of 2-phosphonobutane-1,2,4-tricarboxylic acid, polyamino polyether group methylene phosphine 20 parts by weight of acid polycarboxylic acid are prepared by mixing and stirring.

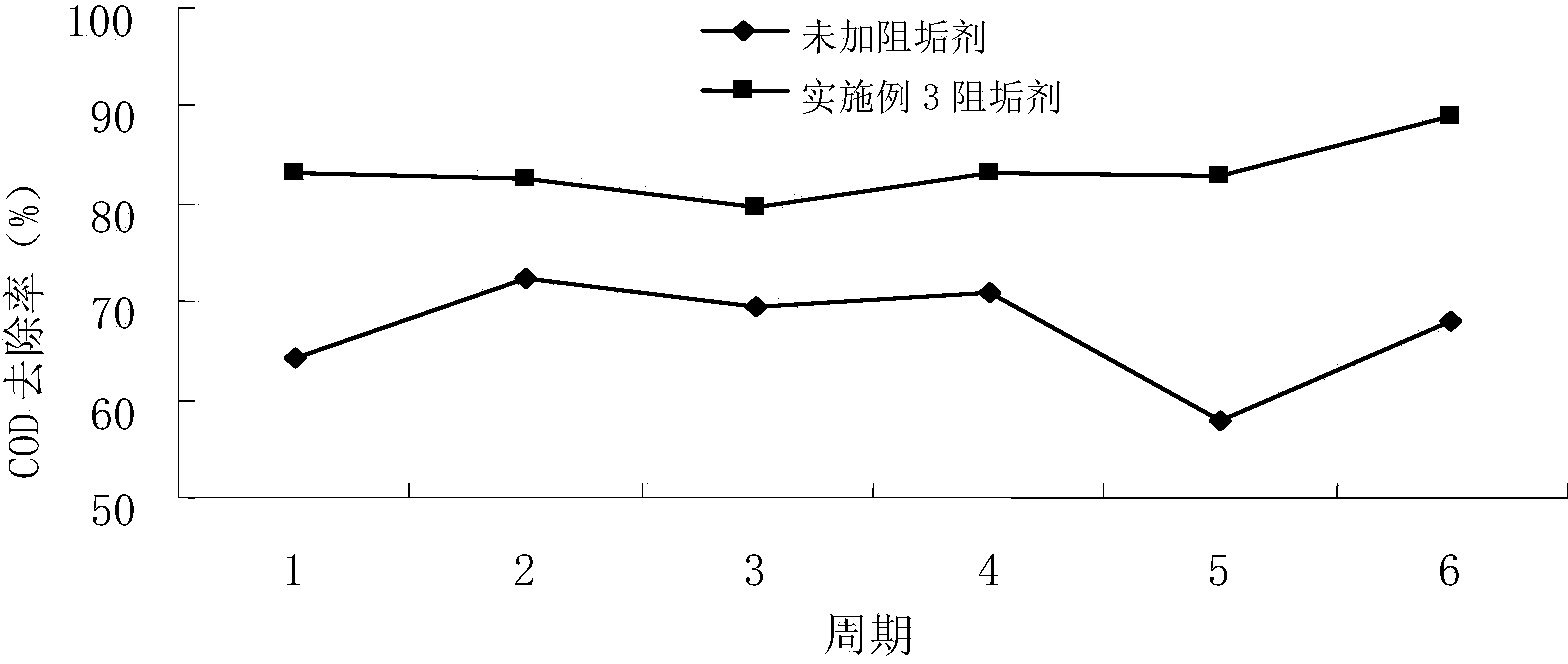

Embodiment 3

[0021] Take 22 parts by weight of acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, 10 parts by weight of 2-phosphonobutane-1,2,4-tricarboxylic acid, polyamino polyether group methylene phosphine 15 parts by weight of acid polycarboxylic acid are prepared by mixing and stirring.

[0022] In order to illustrate the scale inhibition and dispersion effect of the present invention on the treatment of high-phosphorus and high-calcium wastewater by activated sludge, the above-mentioned examples are used to further illustrate its performance below. The water quality of the following experiment is the influent water sample whose pH value was adjusted to be neutral by using alkali to adjust the pH value of the production wastewater in the CaHPO4 recovery process section of a gelatin company.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com