Hollow carbon sphere preparing method

A carbon sphere and hollow technology, applied in the field of preparing nanometer hollow carbon spheres

Active Publication Date: 2015-01-28

CHANGZHOU XIAOGUO INFORMATION SERVICES

View PDF4 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Chinese patent CN 101224883A discloses that anhydrous ethanol is used as carbon source, metal zinc is used as reducing agent and metal solvent, and the nominal diameter is about 400nm prepared by hydrothermal method Hollow carbon spheres, this method has short reaction time and high powder purity, but requires high temperature and high pressure to react, and the cost is high

[0006] In summary, the existing preparation methods mainly have the following disadvantages: one, the synthesis process steps are complicated, the conditions are harsh, and the cost is high; two, the prior art The monodispersity of the synthesized hollow carbon spheres is not good, and the size of the carbon spheres is uncontrollable, which limits the application of hollow carbon spheres as drug carriers in the field of medicine

3. The purity of the synthesized hollow carbon spheres is not high, the template is not easy to remove, and it is easy to cause the hollow carbon spheres to collapse and break when the template is removed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0030] Example 3:

Embodiment 2

[0032] Example 4:

Embodiment 3

[0034] Example 5:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

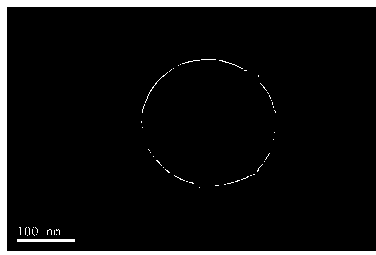

Abstract

The invention discloses a hollow carbon sphere preparing method, and belongs to the technical field of preparing methods of inorganic nonmetal materials. An oxygen-containing organic compound is adopted as a carbon source. A finished product is prepared by adding the oxygen-containing organic compound, a carburizer and a surfactant into a reactor, uniformly mixing by stirring to form reverse microemulsion, heating to 70-200 DEG C to react the compounds for 24-96 h, stopping heating, filtering, washing and drying. The method has advantages of high powder purity, low energy consumption, good monodispersity, good solubility, good chemical stability, easy controllable preparation, large-scale production, and the like.

Description

technical field [0001] The invention relates to a technology for preparing nanometer hollow carbon spheres, and belongs to the technical field of preparation methods of inorganic non-metallic materials. Background technique [0002] As a special carbon material, hollow carbon spheres have high chemical stability, low density, good high temperature heat resistance and biocompatibility, and can be used for catalyst carriers, electrode materials, supercapacitors, hydrogen storage materials, Drug delivery devices and templates for preparing other hollow materials are mainly used in the fields of materials science, medicine, pharmacy and coating industry. [0003] At present, the methods for preparing hollow carbon spheres mainly include: high-temperature pyrolysis of organic matter, vapor deposition, laser distillation, arc discharge, template method, etc. [0004] Rui L et al. ( Angew. Chem. Int. Ed. 2011, 50, 6799-6802) Using dopamine as the carbon source and silica sphere...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B31/02

Inventor 姜兴茂闵建中李亚情梁帅蔡云亮付鑫陈震

Owner CHANGZHOU XIAOGUO INFORMATION SERVICES

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com