Core-shell structure precious metal-nitrogen heterocyclic Carbene polymer magnetic catalyst

A nitrogen heterocyclic carbene, core-shell structure technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, carbon-based compound preparations, etc., can solve problems such as improvement and unfavorable industrial benefits, Achieve the effect of high catalytic activity, reduced industrial cost, and high industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

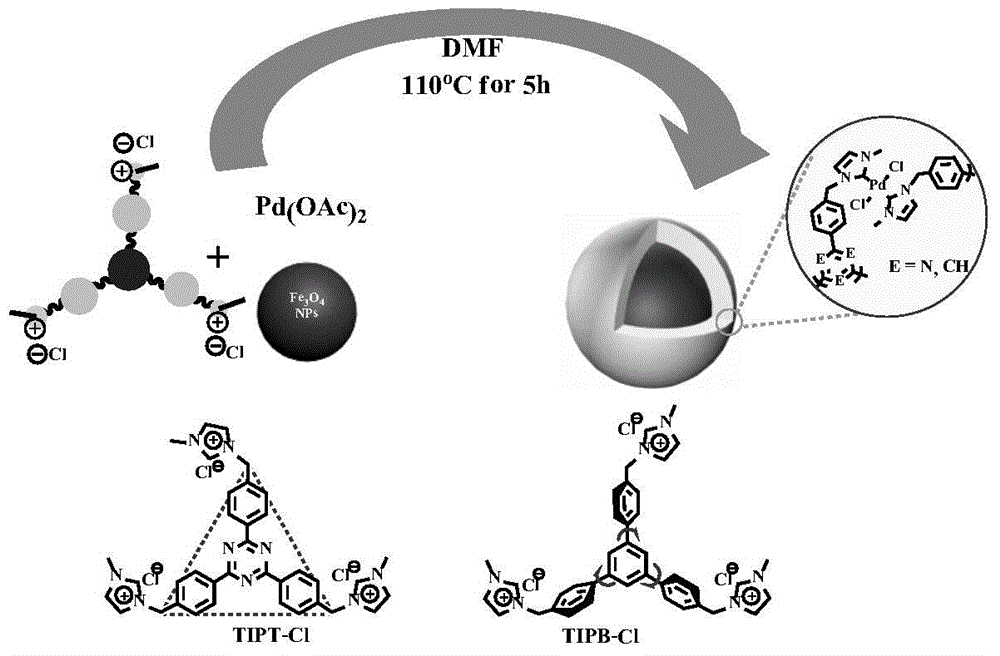

[0015] Embodiment 1 (catalyst Fe 3 o 4 Preparation and application of PNP1)

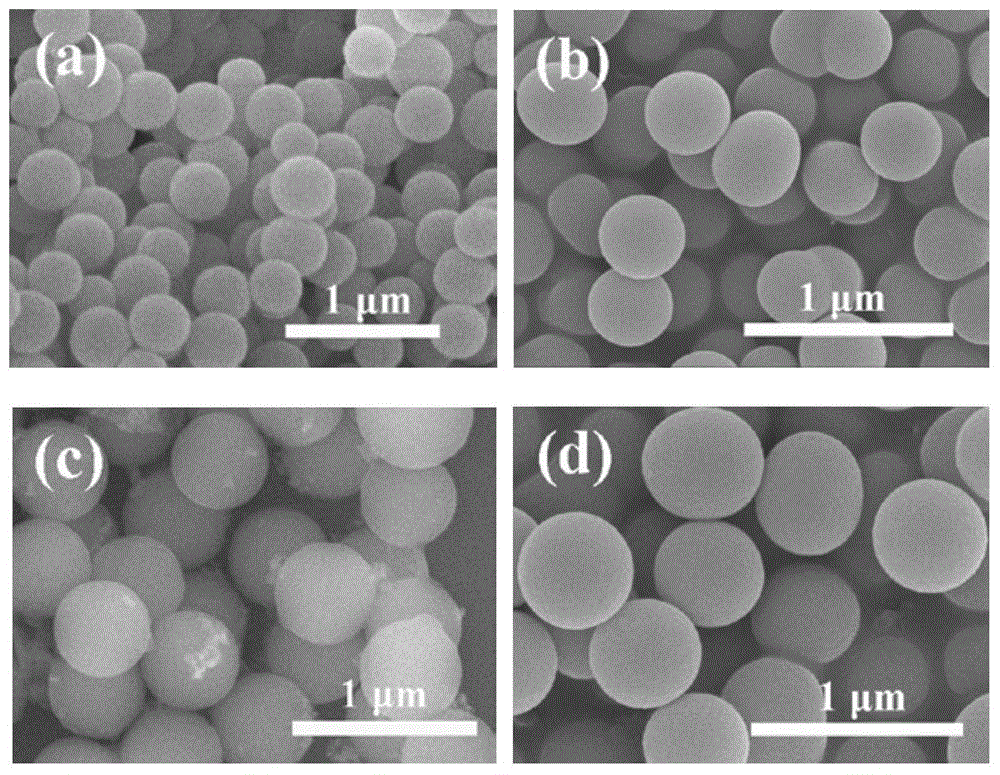

[0016] Dissolve 100 mg of palladium acetate in 10 mL of DMF solution, then add 210 mg of TIPT-Cl and Fe containing imidazolium salt under ultrasonication 3 o 4 Nanoparticles in 70mL DMF solution, and then the reaction system was reacted at 90°C for 1h under ultrasonic conditions, and then reacted at 110°C in an oil bath for 5h. After the reaction was completed, cooled to room temperature, and the obtained solid was collected and separated under an external magnetic field. , and then washed several times with DMF, dichloromethane and ether, and then dried under vacuum to obtain the magnetic spherical catalyst Fe 3 o 4 PNP1.

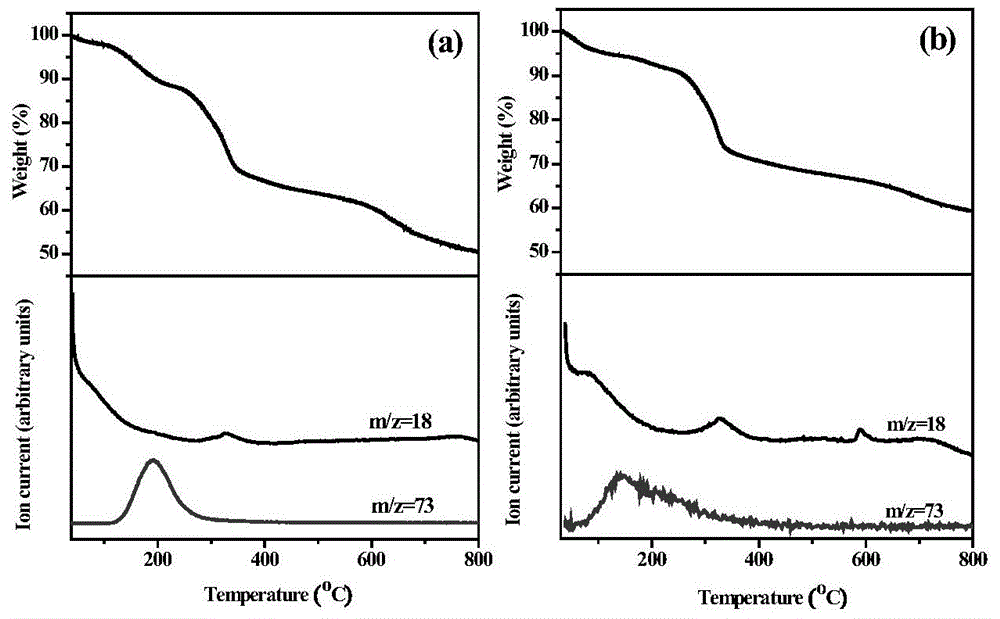

[0017] Catalyst Fe 3 o 4 The content of Pd in PNP1 is 1.07mmol / g and the thermal stability is at least above 250°C.

[0018] Catalyst Fe 3 o 4 PNP1 is used in the Suzuki coupling reaction of 4-bromoacetophenone and phenylboronic acid, the catalyst dosage is 1%, the re...

Embodiment 2

[0019] Embodiment 2 (catalyst Fe 3 o 4 Preparation and application of PNP2)

[0020] Dissolve 100mg of palladium acetate in 10mL of DMF solution, then add to the solution containing 210mg of imidazolium salt TIPB-Cl and appropriate amount of Fe 3 o 4 Nanoparticles in 70mL DMF solution, and then the reaction system was reacted under ultrasonic at 90°C for 1h, and then reacted in an oil bath at 110°C for 5h. After the reaction was completed, cooled to room temperature, the obtained solid was Collect and separate, then wash several times with DMF, dichloromethane and ether, then dry under vacuum to obtain the magnetic spherical catalyst Fe 3 o 4 PNP2.

[0021] Catalyst Fe 3 o 4 The content of Pd in PNP2 is 0.82mmol / g, and the thermal stability is at least 250℃.

[0022] Catalyst Fe 3 o 4 PNP2 is used for the Suzuki coupling reaction of 4-bromoacetophenone and phenylboronic acid, the catalyst dosage is 1%, the reaction temperature is room temperature, the reaction time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com