Polyether sulfone temperature stimulus response film and preparation method thereof

A stimuli-responsive, polyethersulfone technology is applied in the field of polyethersulfone temperature stimuli-responsive membranes and their preparation, which can solve the problems of high production cost, limited temperature-sensitive substances, membrane mechanical defects, etc., and achieves overcoming poor mechanical properties and easy industrialization. Production, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

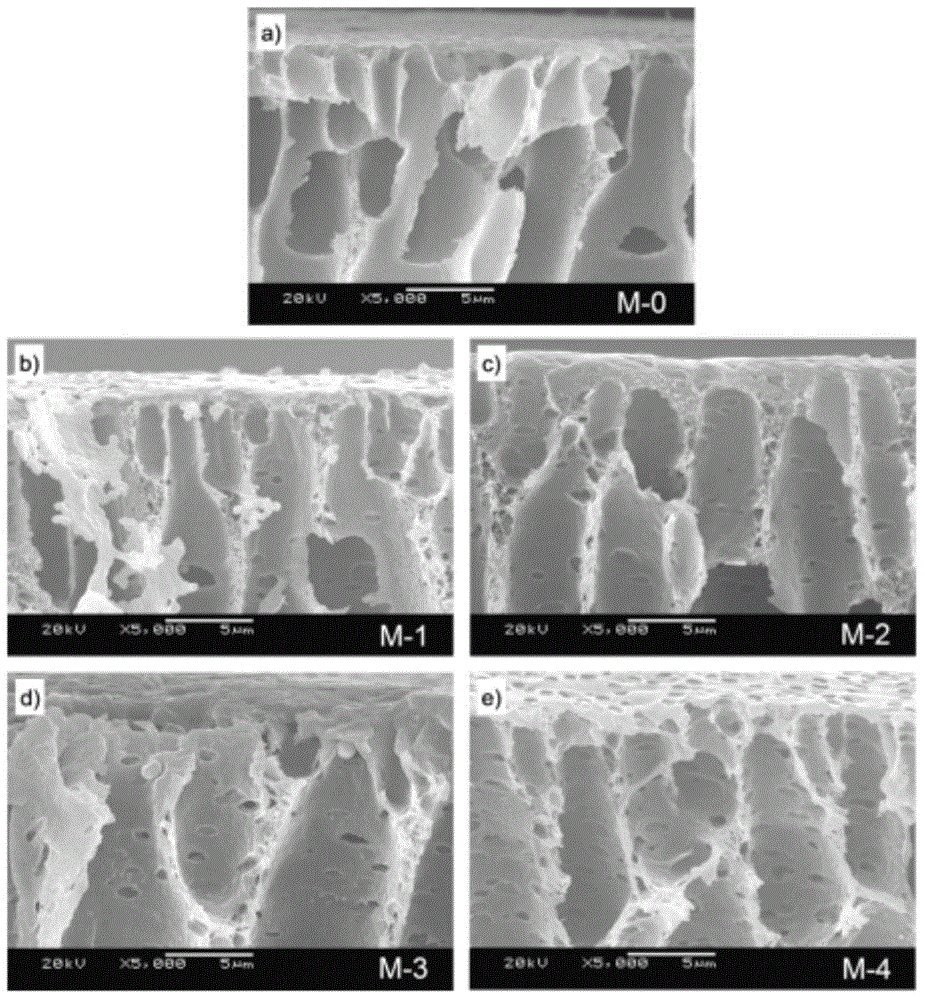

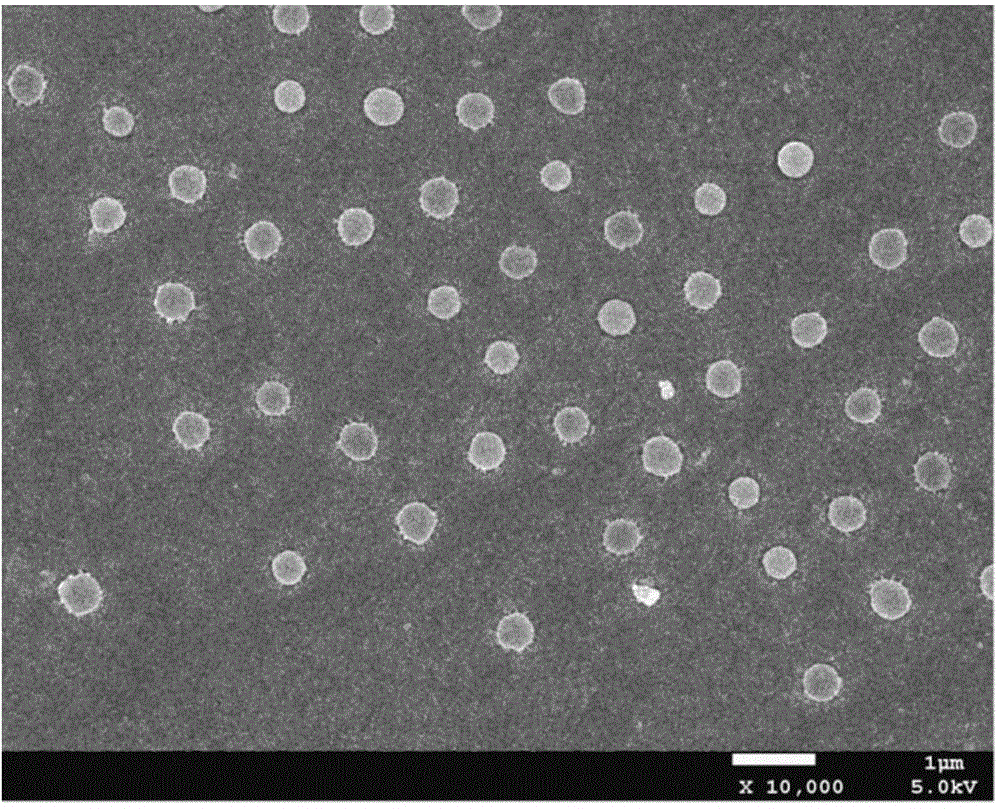

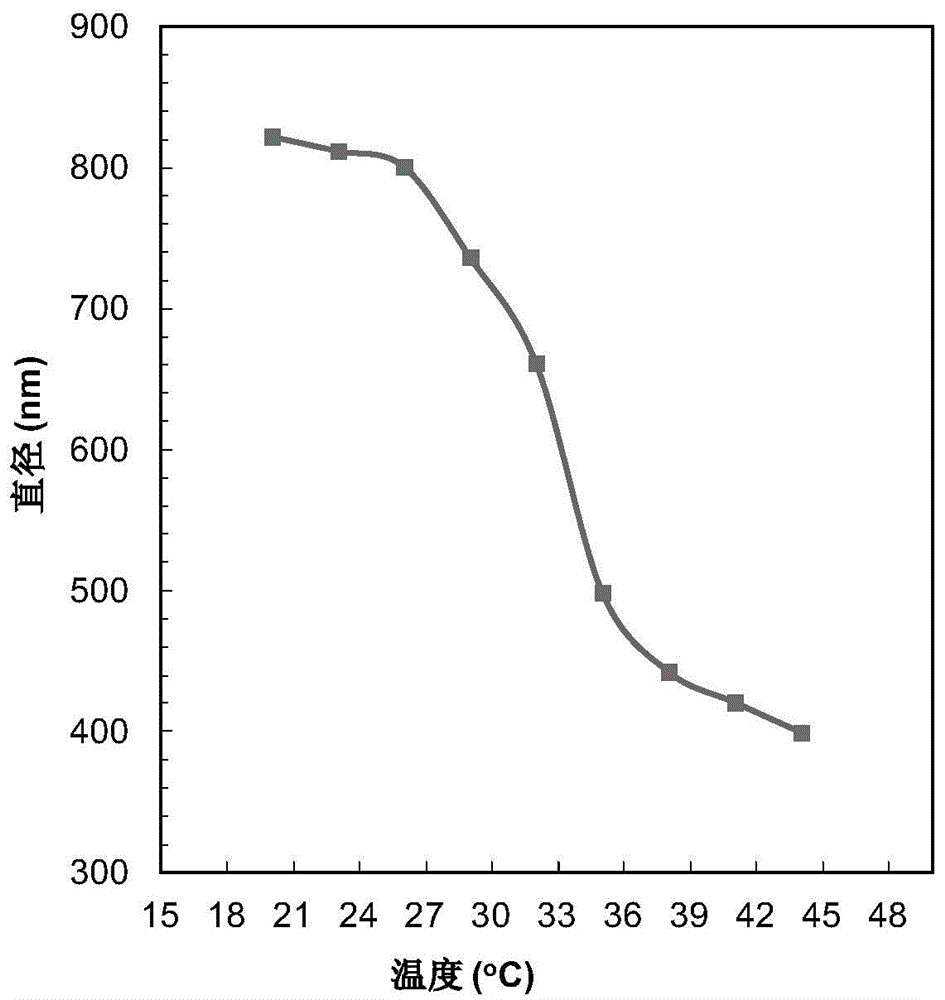

[0036] In this example, the preparation method of the polyethersulfone temperature-stimuli-responsive membrane is as follows:

[0037] (1) With N-isopropylacrylamide and N, N-methylenebisacrylamide as raw materials, ammonium persulfate is used as initiator, the raw material, initiator and deionized water are added in a single-necked flask, stirred Uniformly form a mixed solution, then pass high-purity nitrogen gas into the single-necked flask for 30 minutes to remove the oxygen in the single-necked flask, seal the single-necked flask, and place it in a constant temperature water bath at 70°C to stir for 7 hours;

[0038] The mass ratio of N, N-methylenebisacrylamide to N-isopropylacrylamide is 0.1:1, the mass ratio of ammonium persulfate to N-isopropylacrylamide is 0.02:1, deionized water The mass ratio to N-isopropylacrylamide is 140:1;

[0039] (2) Filter the reaction solution obtained in step (1), and then centrifuge the obtained filtrate at a speed of 8000r / min. After the...

Embodiment 2

[0045] In this embodiment, the process steps of the preparation method of the polyethersulfone temperature-stimulus-responsive membrane are the same as in Example 1, except that the mass ratio of PNIPAM nanogel dry powder to polyethersulfone in step (3) is 8.5:100 .

Embodiment 3

[0047] In this embodiment, the process steps of the preparation method of the polyethersulfone temperature-stimulus-responsive membrane are the same as in Example 1, except that the mass ratio of PNIPAM nanogel dry powder to polyethersulfone in step (3) is 12.75:100 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com