Method for manufacturing steel sheet for grinding and cutting granite stones

A production method and granite technology, applied in the field of steel sheet production, can solve problems such as low tensile strength, fracture, deviation, and dramatic changes in chemical composition, and achieve the goal of overcoming poor mechanical properties, high tensile strength and wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

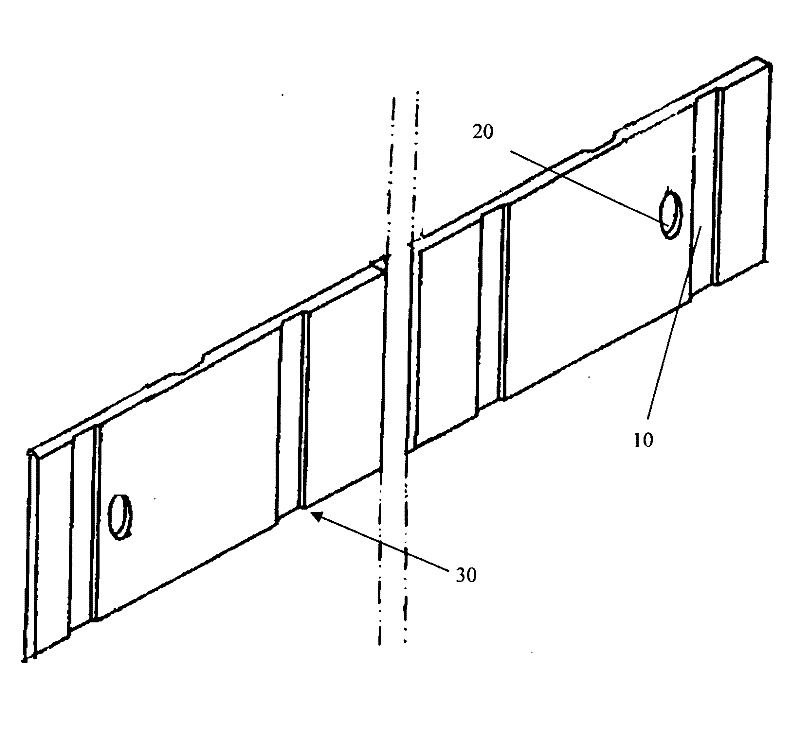

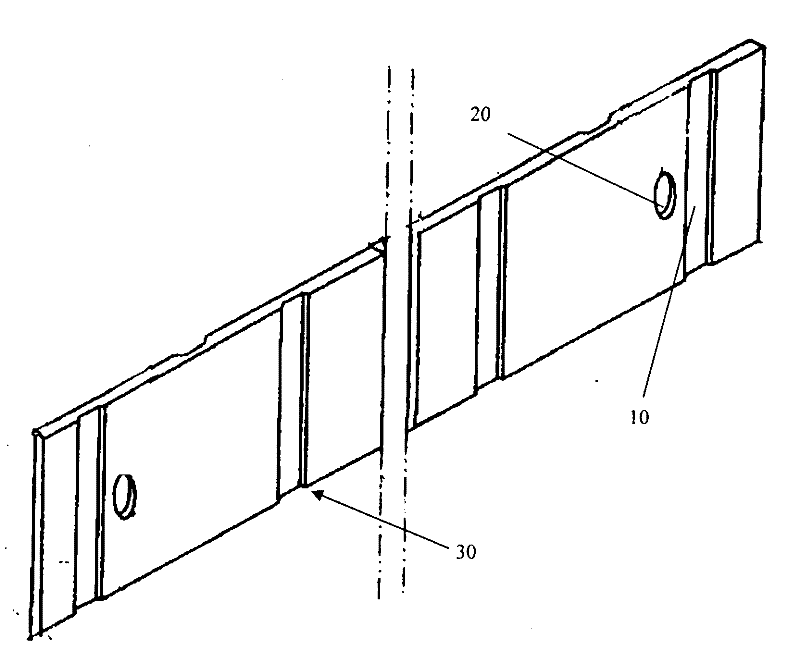

[0022] Such as figure 1 As shown, the steel sheet product to be produced in the present invention has a sand leakage groove 10 on the steel sheet 30, and mounting holes 20 at both ends, which are used to install on the equipment for grinding and cutting granite stones to process granite stones. After long-term research, analysis and comparison of the equipment, processing technology, working principle of the grinding and cutting machine and the mechanical properties required by the steel sheet, the applicant believes that it is best to use waste rails to make grinding and cutting granite. The quality of the steel sheet of the stone cannot meet the requirements of stone processing, only the steel sheet for grinding and cutting granite stone can meet the requirements of stone processing only with the same grade of steel billet. therefore. The present invention adopts billet as raw material to propose a new manufacturing method, and its main technical features are:

[0023] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com