Battery piece feeding conveying mechanism for photovoltaic stringing welding machine

A transmission mechanism and cell technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as efficiency bottlenecks, achieve the effects of improving efficiency, maintaining stability, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings and embodiments.

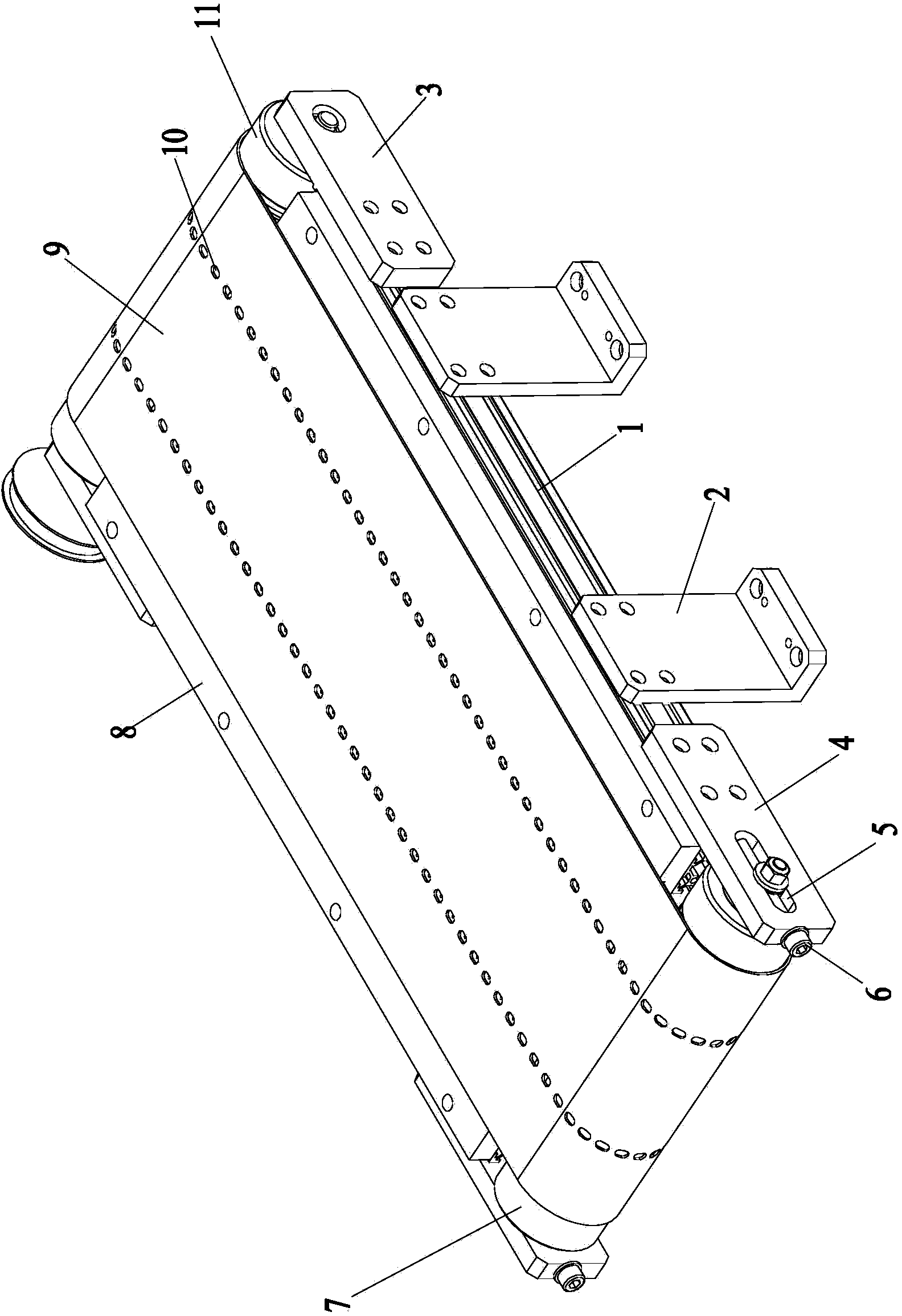

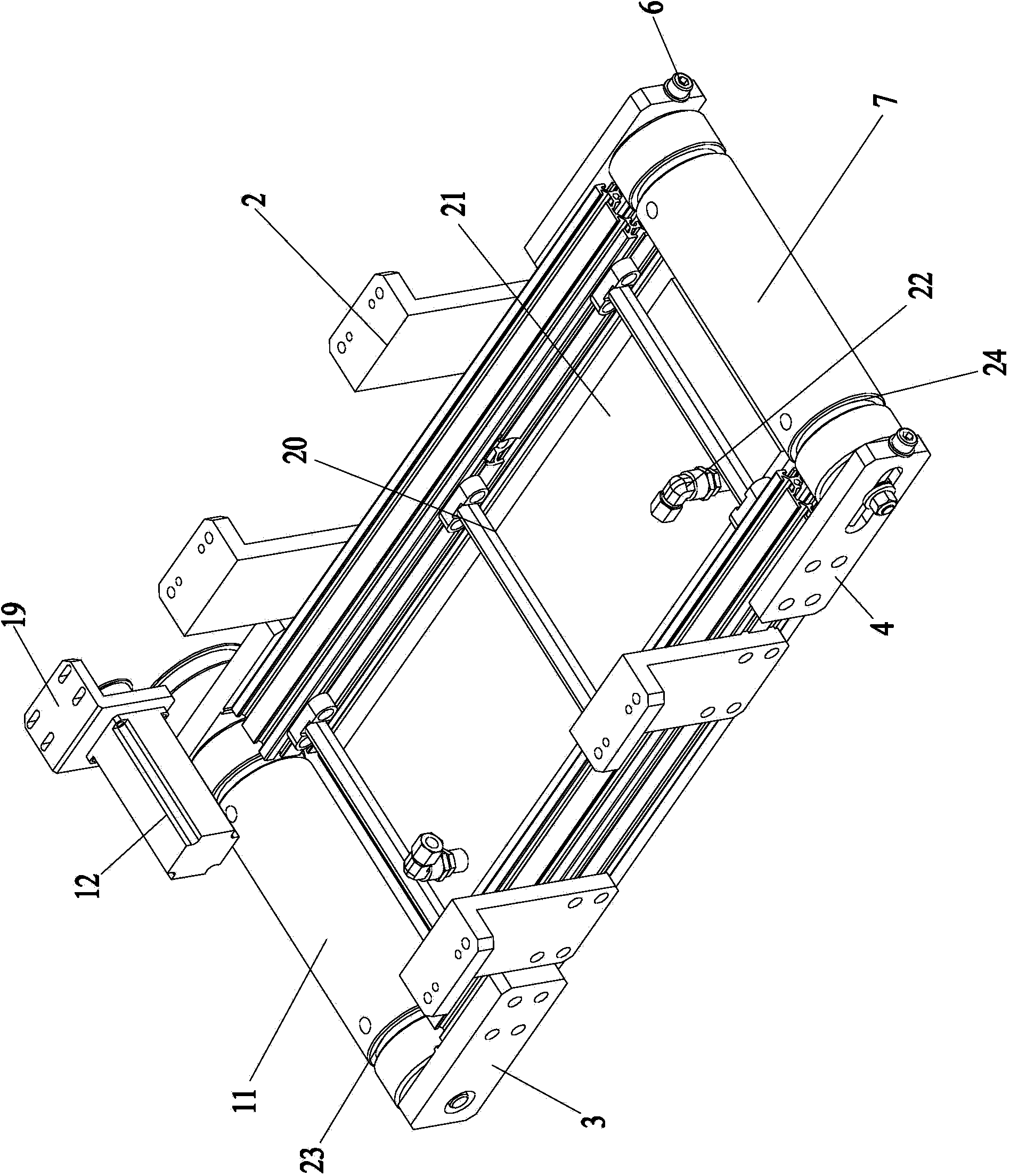

[0020] like figure 1 and figure 2 Shown: In order to improve the efficiency of feeding and transmission, increase the production capacity, reduce the fragmentation rate of cell feeding, and shorten the generation cycle, the present invention includes a transmission frame, and the transmission frame has a first frame end and is connected to the first The second frame end corresponding to the frame end; a driving wheel 11 is installed on the first frame end of the transmission frame, and a driven wheel 7 is installed on the second frame end of the transmission frame, and the driven wheel 7 and the driving wheel 11 are connected by the transmission belt 9 installed on the transmission frame body, and the transmission belt 9 is provided with a number of belt air holes 10 passing through the transmission belt 9, and the belt air holes 10 can be connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com