Heat exchanger integrated assembly

A technology of heat exchangers and components, applied in the direction of indirect heat exchangers, heat exchanger shells, heat exchanger types, etc., can solve the problems of complex connection structure of plate heat exchangers, affecting cooling effect, and low vibration resistance , to achieve the effect of avoiding pipe breakage, small number of parts and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention provides a heat exchanger integration device. The integration device of the invention can integrate the heat exchanger and the expansion valve without pipeline connection, and has simple structure, high stability and good vibration resistance.

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings.

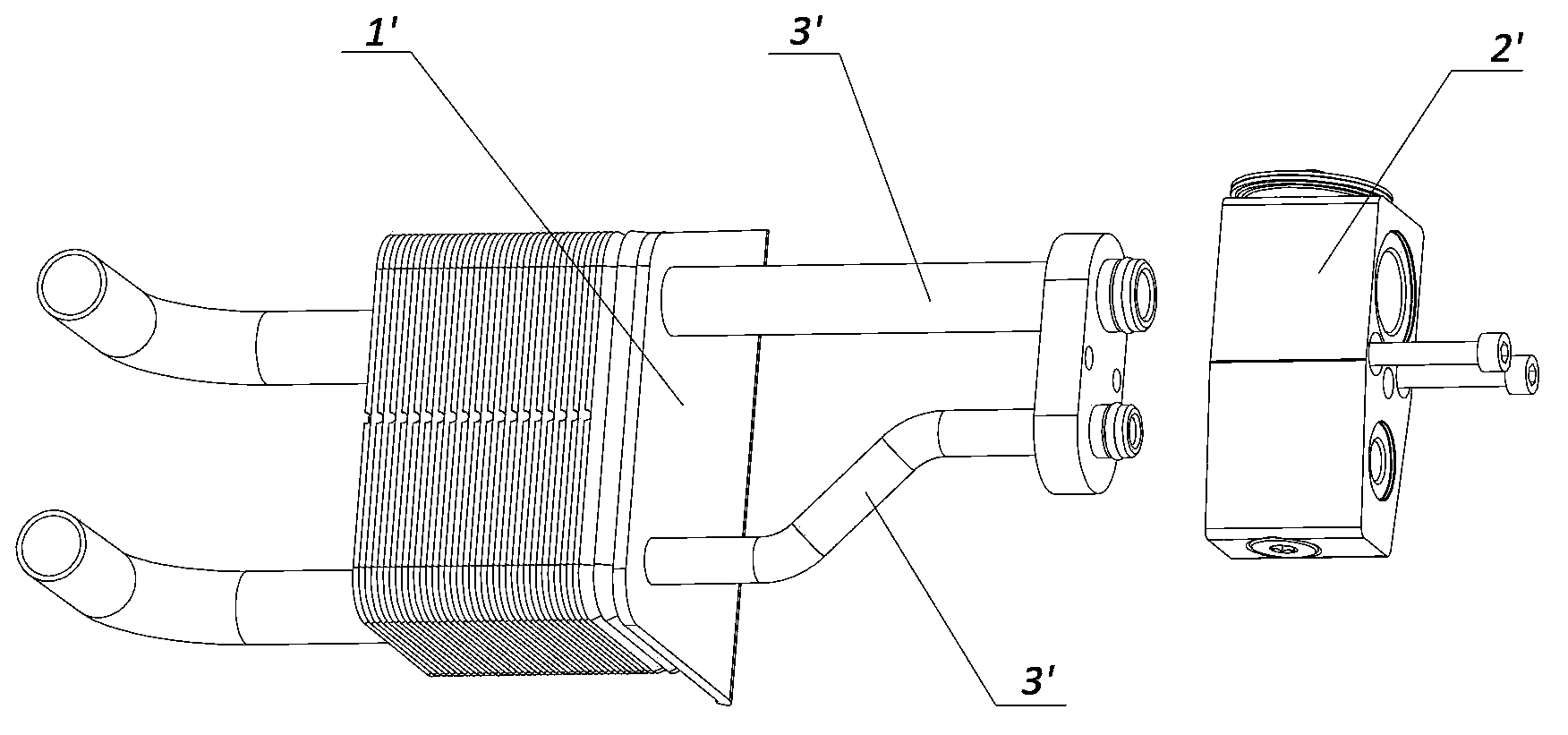

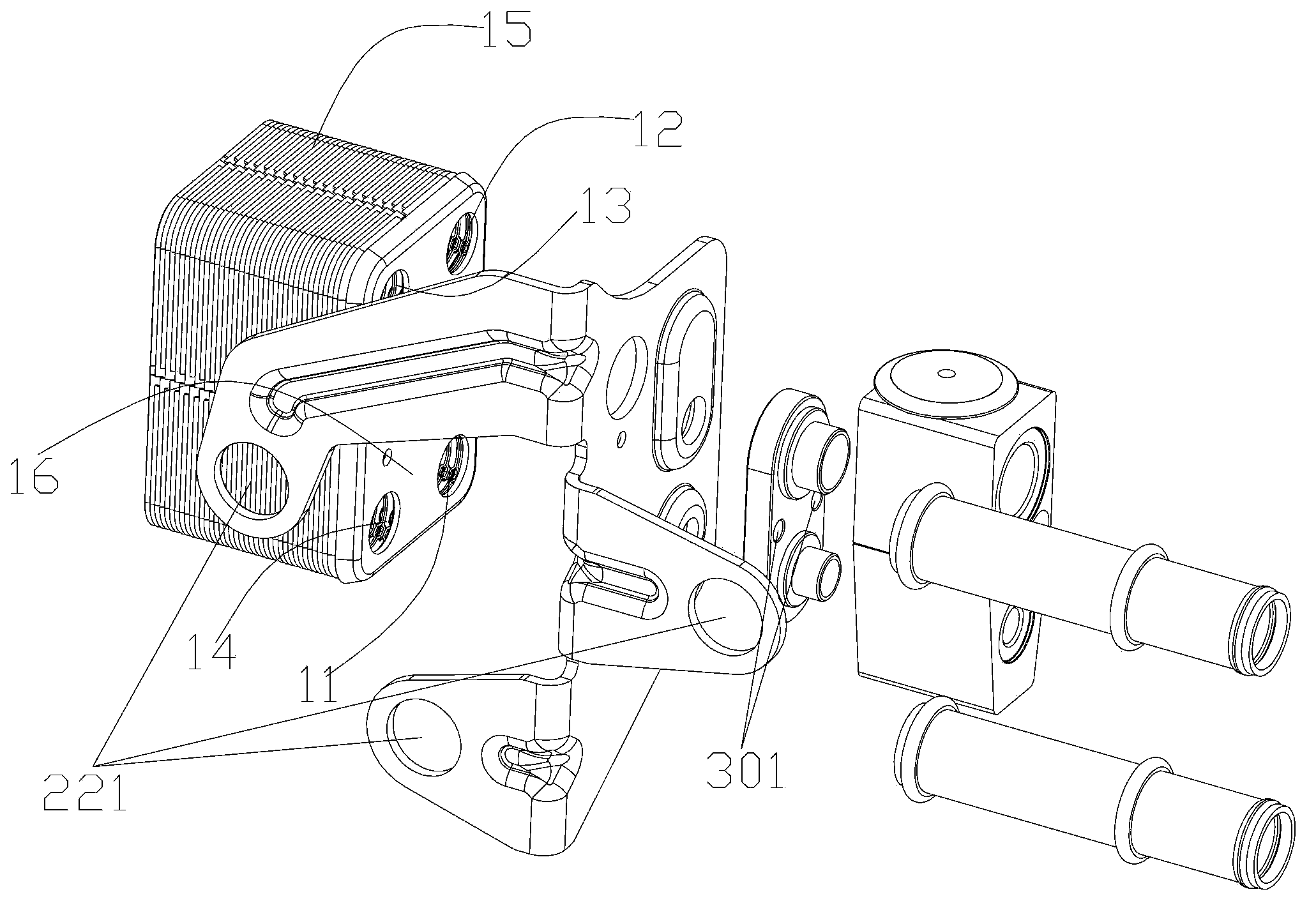

[0036] figure 2 It is a three-dimensional schematic diagram of the heat exchanger integrated assembly of the present invention.

[0037] Such as Figure 2 to Figure 4 As shown, the present invention discloses a heat exchanger integrated assembly 100, including a heat exchanger 1, a mounting bracket 2 for installing the heat exchanger integrated assembly 100 on other devices, and an adapter device 3 fixed on the mounting bracket 2 , the heat exchanger integrated assembly may further include an expansion valve 4, wherein the expansion valve is detachably installed on the heat exchanger integrated assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com