Rigid-foam polyurethane heat-preserving and decorating integration plate and manufacturing method thereof

A rigid foam polyurethane and polyurethane board technology, applied in chemical instruments and methods, lamination devices, lamination and other directions, can solve the problems of inability to form at one time, complicated production process, etc., achieve high production efficiency, simplify operation procedures, realize The effect of product standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

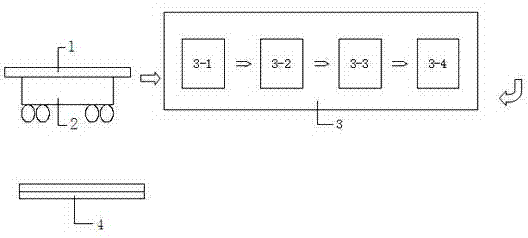

Image

Examples

Embodiment 1

[0028] A hard foam polyurethane thermal insulation and decorative integrated board, comprising a decorative board 1, a BOPP film 5, a polyurethane board 6, and a cement fiberglass felt 7; the lower surface of the decorative board 1 is covered with the BOPP film 5; the upper surface of the decorative board 1 is covered with polyurethane The board 6 is bonded, and the bonding method is pouring; the upper surface of the polyurethane board 6 is bonded with a cement glass fiber mat 7 .

[0029] The decorative board 1 is based on calcium silicate, and the decorative board 1 is finished with at least one of fluorocarbon paint, real stone paint, decorative mortar, facing brick, stone material and transfer printing. The polyurethane board 6 has a thickness of 3 to 6 cm and a combustion rating of B. That The thickness of the decorative board 1 is 0.6~1.2cm, and the water absorption is ≤500g / m 2 , Aging resistance 1000h is qualified.

[0030] The specific preparation method of the abo...

Embodiment 2

[0034] It is further preferred on the basis of implementation 1, wherein the thickness of the polyurethane board 6 is 4cm, the thickness of the decorative board 1 is 0.8cm, and the surface material of the decorative board 1 is real stone paint.

Embodiment 3

[0036] It is further preferred on the basis of implementation 1, wherein the thickness of the polyurethane board 6 is 5 cm, the thickness of the decorative board 1 is 1 cm, and the surface material of the decorative board 1 is stone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com