Low-corrosion and high-efficiency chlorine salt deicing agent and preparation method thereof

A snow-melting agent and low-corrosion technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of destroying the ecological environment around the road infrastructure, metal, concrete corrosion, high price and cannot be promoted, and achieve enhanced corrosion inhibition Effect, low cost, mild condition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following examples are a further description of the content of the present invention as an explanation of the technical content of the present invention, but the essential content of the present invention is not limited to the following examples, those of ordinary skill in the art can and should know any Simple changes or replacements of the essential spirit of the invention shall fall within the scope of protection required by the present invention.

[0043] (1) Formula of low-corrosion and high-efficiency chlorine salt deicing agent

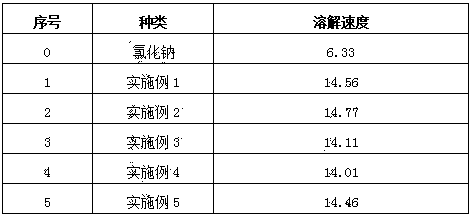

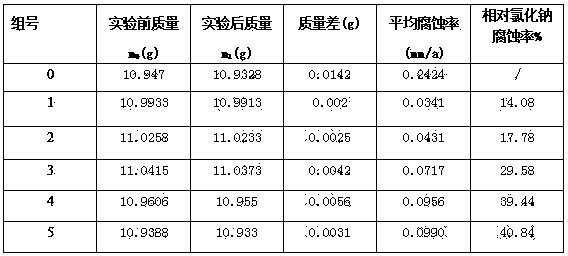

[0044] Table 1 lists 5 kinds of representative embodiments, wherein said numerical value refers to the weight percent of each component in the deicing agent.

[0045] Table 1 The formulation composition of low-corrosion and high-efficiency chloride salt deicing agent

[0046] Formula composition Sodium chloride Example 1 Example 2 Example 3 Example 4 Example 5 Sodium chloride 100 90 92.5 91.5 92 93.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com