Application of zinc isoocatanoate in reduction on agglomeration of white carbon black, white carbon black dispersing agent containing zinc isoocatanoate and preparation method thereof

A technology of zinc isooctanoate and white carbon black, which is applied in the field of fine chemicals, can solve the problems of serious environmental pollution and relatively expensive prices, and achieve the effects of improving mechanical properties, shortening mixing time, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

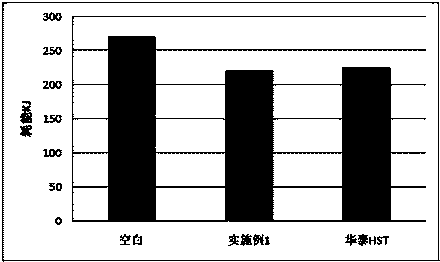

Examples

Embodiment 1

[0049] The formula of the white carbon black dispersant of the present invention is: 90 parts of zinc isooctanoate, 40 parts of polyethylene glycol 2000, 5 parts of fatty acid ester, 15 parts of calcium carbonate.

[0050] The preparation method is: Stir and melt zinc isooctanoate, polyethylene glycol 2000 and rubber protective wax at 80°C, then add calcium carbonate at a temperature of 90°C, stir and mix evenly, pour out and cool to make tablets or melt granulate. Obtain the white carbon black dispersant of the present invention.

Embodiment 2

[0052] The formula of the white carbon black dispersant of the present invention is: 90 parts of zinc isooctanoate, 40 parts of polyethylene glycol 4000, 5 parts of fatty acid ester, and 15 parts of calcium carbonate. The preparation method is the same as in Example 1.

Embodiment 3

[0054] The formula of the white carbon black dispersant of the present invention is: 90 parts of zinc isooctanoate, 40 parts of polyethylene glycol 6000, 5 parts of fatty acid ester, and 15 parts of calcium carbonate. The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com