A kind of composite coagulant for removing cyanobacteria without damage and its preparation method and application

A coagulant and blue-green algae technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of destroying algal cell walls and releasing intracellular algal toxins, etc. Achieve the effects of simple operation process, good stability, and significant social and economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

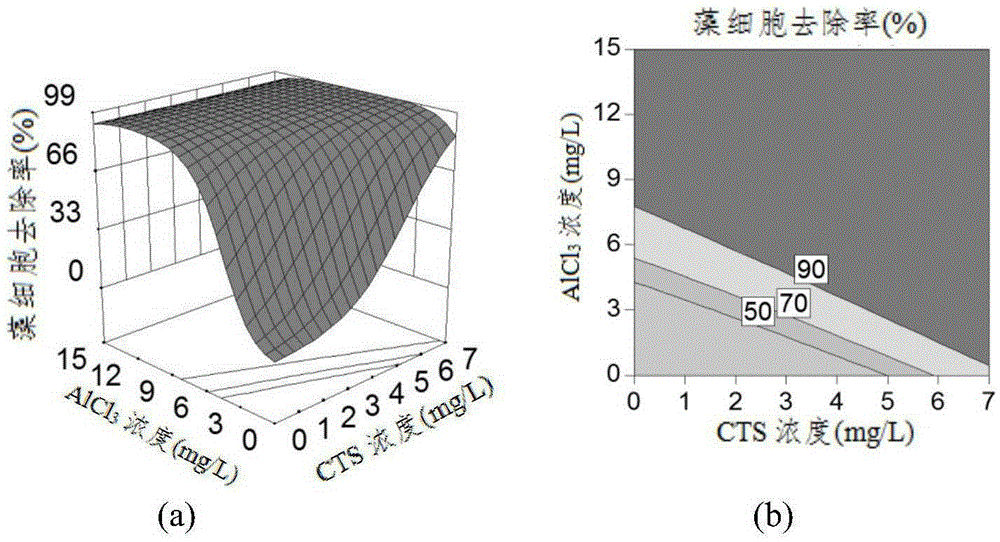

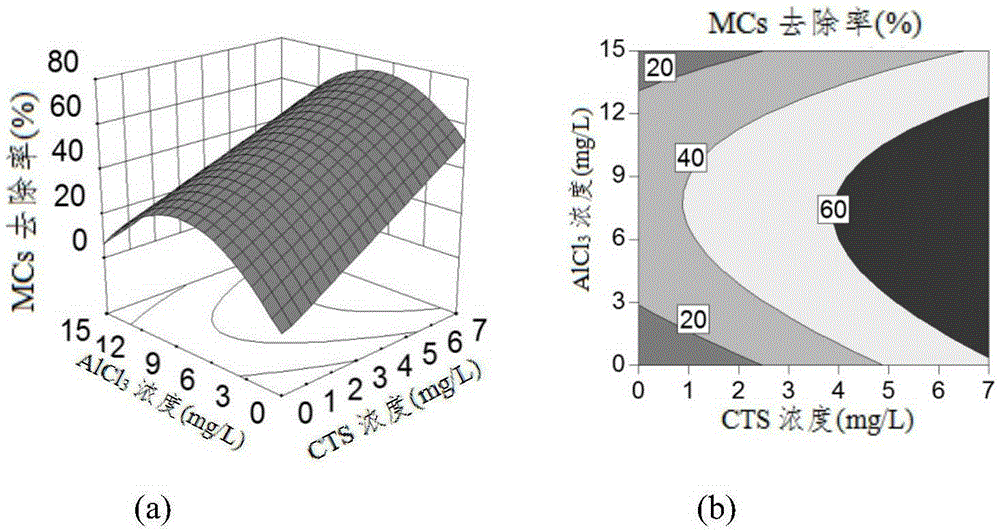

[0025] Embodiment 1 The present invention CTS-AlCl 3 Selection of Composite Coagulant

[0026] Determine CTS-AlCl of the present invention by response surface method 3 The optimal coagulant parameters of composite coagulant are: CTS concentration 2.5mg / L, AlCl 3 With a concentration of 7.5mg / L, the predicted optimum removal rate of Microcystis aeruginosa was 96.28%, and the concentration of extracellular microcystin was 51.59%. The verification test is carried out on the parameters obtained from the response surface, and the specific operation process is as follows:

[0027] 1) CTS-AlCl 3 Preparation of composite coagulant

[0028] a) Chitosan (CTS) is produced by Qingdao Haisheng Biological Engineering Co., Ltd. Weigh 100mg of CTS, add 10mL of 1% acetic acid solution and stir continuously to dissolve it completely, then add distilled water to 100mL to obtain a 1g / LCTS stock solution.

[0029] b), aluminum chloride (AlCl 3 ) stock solution 3g / L: 1.5g analytically pure Al...

Embodiment 2

[0034]In this study, M.aeruginosa FACHB-905, a typical MCs toxin-producing algae species, was selected as the coagulation treatment object. The samples of Prototheca were cultured in BG11 culture medium, under the conditions of 14h / 10h photoperiod and constant temperature at 25°C. Harvest the algae cells at the end of the logarithmic growth phase (about 10 days after culture).

[0035] Take 1L of Microcystis aeruginosa suspension and place it in a 1L beaker, place the beaker on a six-coagulation mixer and start stirring immediately, and start timing at the same time. The microcystis aeruginosa suspension to be treated was stirred rapidly for 30 seconds, and after mixing evenly, the above-mentioned composite coagulant (adding concentration was 10 mg / L) was added respectively in the beaker, after continuing to stir rapidly for 2 minutes, turn to slow stirring for 20 minutes, and finally Place precipitation for 30min, the fast stirring speed is 250r / min, and the slow stirring sp...

Embodiment 3

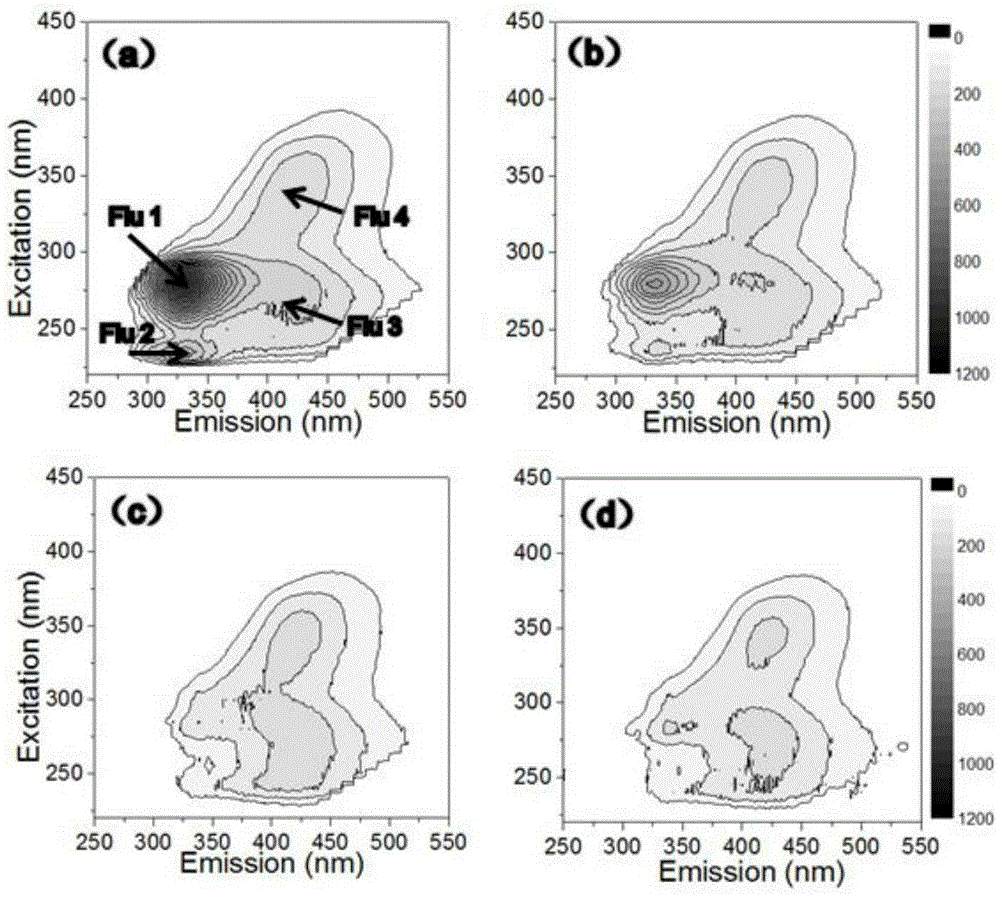

[0065] Example 3AlCl 3 , CTS and CTS-AlCl 3 Comparison of Effects of Compound Coagulants on Removal of Extracellular Polymers

[0066] The preparation concentration is 2×10 6 cell / mL algae liquid, take three 1L beakers and take 1L of Microcystis aeruginosa suspension, place the beakers on a six-coagulation mixer and start stirring immediately, and start timing at the same time. The Microcystis aeruginosa suspension to be treated was stirred rapidly for 30s, and after mixing evenly, 10mg / L of CTS-AlCl of the present invention was added to 3 beakers respectively 3 Compound coagulant, 7mg / LCTS flocculant (the optimal dose of CTS alone), 15mg / LAlCl 3 Coagulant (adding AlCl alone 3 optimal dosage). After continuing to stir rapidly for 2 minutes, turn to slow stirring for 20 minutes, and finally let it settle for 30 minutes. The fast stirring speed is 250r / min, and the slow stirring speed is 20r / min.

[0067] Since extracellular polymeric EOM forms disinfection by-products du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com