A brazing process suitable for dissimilar metals of steel and aluminum and its brazing connector

A dissimilar metal and brazing technology, which is applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of product use range and performance limitations, and achieve the goal of controlling adverse effects, ensuring welding quality, and promoting wetting and spreading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

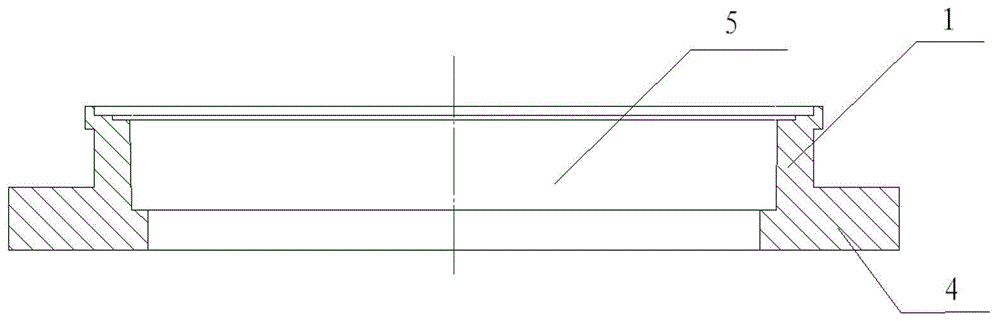

[0030] Example 1: Ф47mm inner diameter specification 1Cr18Ni9Ti / 6A02 conduit structure brazing

[0031] 1) Remove oil and oxide film by conventional aluminum alloy surface cleaning methods for aluminum rings, process cores and solder;

[0032] 2) The surface of stainless steel needs to be nickel-plated, and the thickness of the coating is 20 μm;

[0033] 3) Raise the crucible furnace to the set furnace temperature in advance before brazing, and set the furnace temperature to 660°C;

[0034] 4) Put the process core into the aluminum ring;

[0035] 5) Rivet the bottom of the combined semi-finished product of the process core and the aluminum ring to achieve bottom sealing;

[0036] 6) Press the steel ring into the annular gap formed by the process core and the aluminum ring, and measure the height difference between the upper surface of the process core and the upper surface of the inner ring platform of the steel ring at four symmetrical points to ensure that the height diffe...

example 2

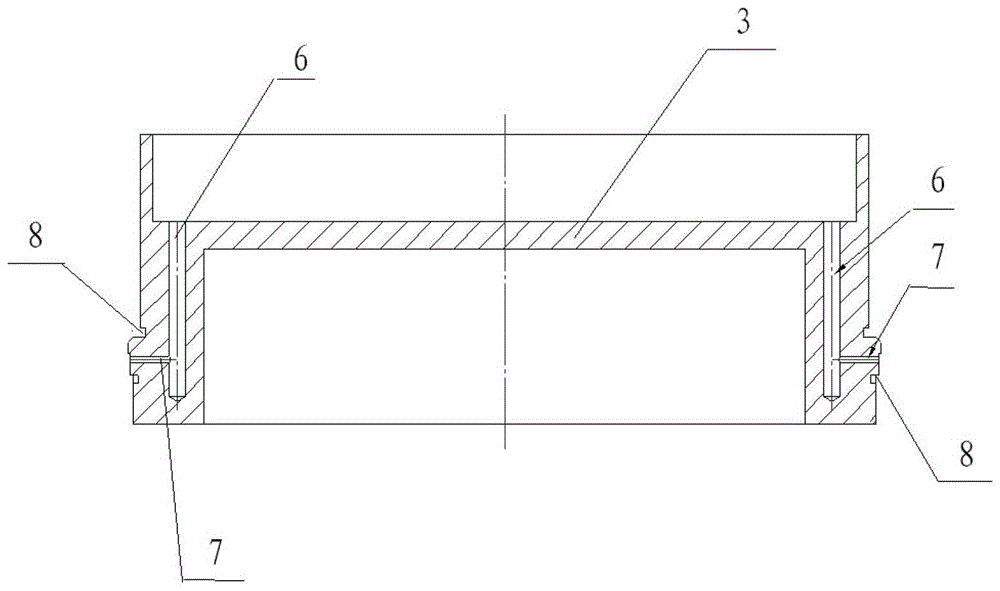

[0042] Example 2: Ф220mm inner diameter specification 1Cr18Ni9Ti / 6A02 conduit structure brazing

[0043] 1) Remove oil and oxide film by conventional aluminum alloy surface cleaning methods for aluminum rings, process cores and solder;

[0044] 2) Nickel plating is required on the surface of stainless steel, with a thickness of 30 μm;

[0045] 3) Raise the crucible furnace to the set furnace temperature in advance before brazing, and set the furnace temperature to 720°C;

[0046] 4) Put the process core into the aluminum ring;

[0047] 5) Rivet the bottom of the combined semi-finished product of the process core and the aluminum ring to achieve bottom sealing;

[0048] 6) Press the steel ring into the annular gap formed by the process core and the aluminum ring, and measure the height difference between the upper surface of the process core and the upper surface of the inner ring platform of the steel ring at four symmetrical points to ensure that the height difference after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com