A three-dimensional porous fiber scaffold, preparation method and application

A fiber scaffold and three-dimensional porous technology, which is applied in the field of three-dimensional porous fiber scaffold, medical materials and its preparation, and can solve the problems of unstudied tensile mechanical properties, low tensile strength and elongation rate, low CPC strength, etc. problems, to achieve good expandability, improve conductivity, fine fiber diameter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

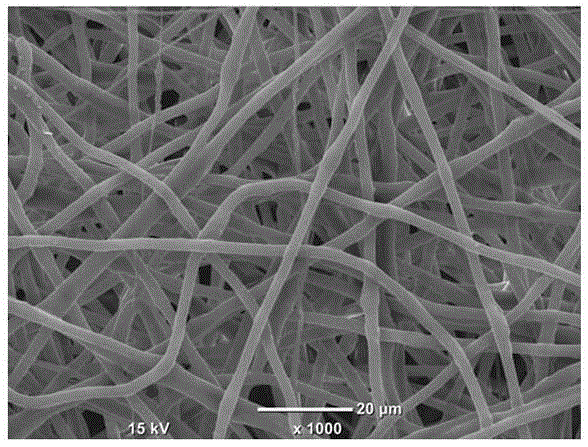

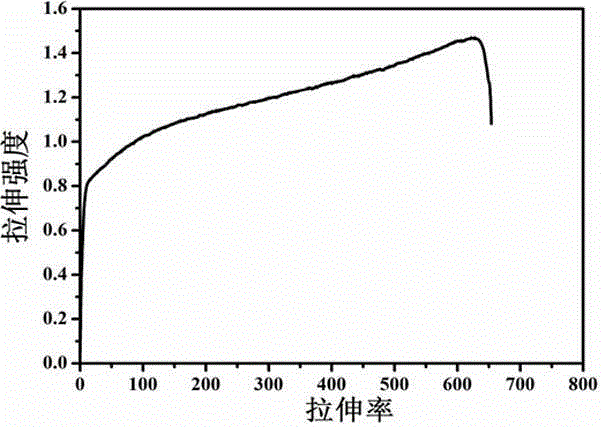

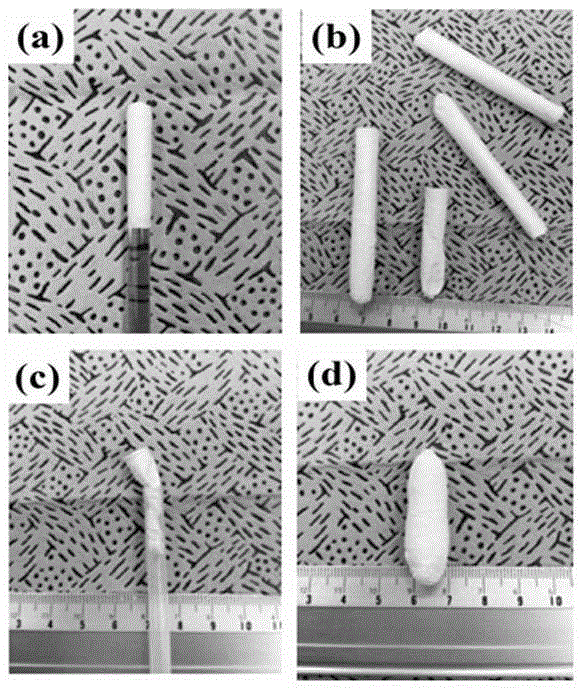

Embodiment 1

[0029] Take by weighing 4g of P3HB4HB, wherein the molar content of 4HB is 18%, slowly adding the weighed P3HB4HB to the mixed solvent of 46g of chloroform and acetone mass fraction ratio is 75:25, about 4 under the condition of magnetic stirring Hour, can obtain the solution that polymer concentration is 8wt%. Then transfer the polymer solution to a 10ml glass syringe and place it in an electrospinning device. By adjusting the voltage to 10kV, the extrusion rate is 3ml / h, and the distance from the needle to the receiving device is 14cm, fibers can be obtained under this condition Fiber membrane with uniform diameter distribution and good shape. When the fiber membrane reaches 50 μm, the spinning process is stopped, and the fiber membranes are collected directly with a glass rod, and this process is repeated 3 times to increase the thickness of the scaffold wrapped on the glass rod, and the thickness can be controlled by the number of repetitions. Wrap the obtained scaffold w...

Embodiment 2

[0035] Weigh 4g of P3HB4HB, wherein the molar content of 4HB is 18%. Slowly add the weighed P3HB4HB into 46g of chloroform solvent for about 4 hours under the condition of magnetic stirring to obtain a solution with a polymer concentration of 8wt%. Then transfer the polymer solution to a 10ml glass syringe and place it in the electrospinning device. By adjusting the voltage to 10kV, the extrusion rate is 3ml / h, and the distance from the needle to the receiving device is 14cm, fibers can be obtained under these conditions Fiber membrane with uniform diameter distribution and good shape. The fibrous membrane obtained under this condition could not be successfully collected on the glass rod, and the three-dimensional elastic scaffold could not be successfully prepared.

Embodiment 3

[0037] The P3HB4HB that takes 4g, wherein the molar content of 4HB is 18%, slowly the P3HB4HB that weighs is added to the mixed solvent that the chloroform of 46g and acetone mass fraction ratio are 50:50, about 4 under the condition of magnetic stirring Hour, can obtain the solution that polymer concentration is 8wt%. Then transfer the polymer solution to a 10ml glass syringe and place it in an electrospinning device. By adjusting the voltage to 10kV, the extrusion rate is 3ml / h, and the distance from the needle to the receiving device is 14cm, fibers can be obtained under this condition Fiber membrane with uniform diameter distribution and good shape. When the fiber membrane reaches about 50 μm, the spinning process is stopped, and the fiber membrane is collected directly with a glass rod, and this process is repeated 3 times to increase the thickness of the scaffold wrapped on the glass rod, and the thickness can be controlled by the number of repetitions. Wrap the obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com